Marine transportation safety investigation report M17C0060

Mooring accident

Bulk carrier Nord Quebec

Trois-Rivières, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content.

-

Table of contents

Summary

On 22 May 2017, the second officer on the bulk carrier Nord Quebec was fatally injured during a mooring accident while the vessel was berthing at section 16 of the Port of Trois-Rivières, Quebec. There was no damage to the vessel, and no pollution was reported.

Le présent rapport est également disponible en français.

Factual information

Particulars of the vessel

| Name of the vessel | Nord Quebec |

| IMO* number | 9612296 |

| Port of registry | Singapore |

| Flag | Singapore |

| Type | Bulk carrier |

| Materials | Steel |

| Gross tonnage | 22 850 tons |

| Length, overall | 177.85 m |

| Draft (summer) | 10.87 m |

| Built | 2013, Onomichi Dockyard Company Ltd., Japan |

| Propulsion | 1 low-speed 2-stroke diesel engine (8280 kW) driving a single 5‑blade fixed-pitch propeller |

| Cargo | None (ballast condition) |

| Crew | 19 |

| Registered owner | Norden Shipping Singapore Pte Ltd., Singapore |

| Manager | Dampskibsselskabet Norden A/S, Denmark |

* International Maritime Organization

Description of the vessel

The Nord Quebec (Figure 1) is a double-hulled bulk carrier with a summer deadweight of 36 546 tonnes, fitted with four 30-tonne electrohydraulic deck cranes. The vessel is built of steel and has 5 cargo holds. The machinery spaces and accommodations are located aft. The vessel is propelled by a diesel engine with a maximum continuous rating of 8280 kW at 129 revolutions per minute. The vessel has no bow thruster.

The forward mooring station is located on the forecastle deck. The port and starboard mooring units are of the windlass-winch combination type. Each unit has 2 mooring line drums (inner and outer), an anchor chain windlass, a warping drum (capstan head) at the outboard extremity, and hand-operated friction band brakes. A single variable-speed radial piston hydraulic motor drives each unit, and jaw clutches allow the operator to select the component to be operated. The investigation determined that at the time of the occurrence, the forward mooring units were in working condition with no apparent defect.

The mooring lines of the Nord Quebec consist of DNV GL‑type approved 8-strand mixed polymer (polyolefin and high-tenacity polyester) ropes 48 mm in diameter, with a certified minimum breaking load of 451 kilonewtons. At the time of the occurrence, the 2 ropes being used as forward spring linesFootnote 1 were in good condition with no apparent defect.

History of the voyage

On 17 May 2017, the Nord Quebec departed in ballast condition from Port Alfred, Quebec, and proceeded to the anchorage off Trois-Rivières, Quebec, to undergo a grain pre-loading inspection.

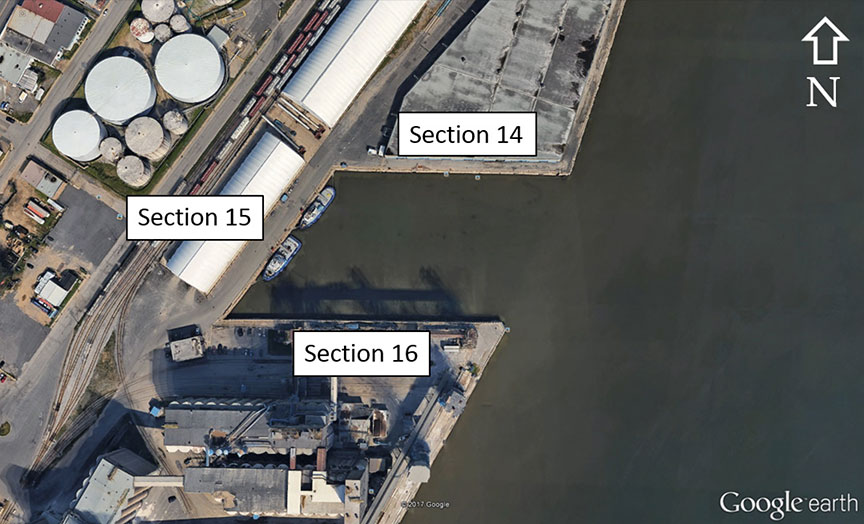

On 22 May at 1342,Footnote 2 a pilot and 2 apprentices from the Corporation des pilotes du Saint-Laurent central had boarded the Nord Quebec and arrived on the navigation bridge to berth the vessel port side to the jetty at section 16 of the Port of Trois-Rivières (Appendix A). The docking manoeuvre and mooring plan were discussed and agreed upon during a formal master/pilot exchange. At 1400, the tugs Ocean Bravo and Ocean Charlie were made fast at the starboard shoulder and quarter of the vessel, and the anchor was weighed at 1402. At that time, the bridge team consisted of the pilot, the 2 apprentices, the master, the chief officer, and 1 helmsman.

The Nord Quebec left the anchorage zone and proceeded upstream at an average speedFootnote 3 of 1.6 knots. At 1436, the pilot ordered a starboard alteration to enter the basin of sections 14, 15, and 16 (Appendix B). While the third officer was in charge of the aft mooring station, the second officer was in charge of the forward mooring station, with the assistance of the bosun operating the windlass controls, and 1 ordinary seaman and 1 able seafarer deck handling the mooring lines on the forecastle deck. The second officer, third officer, bosun, and master communicated using portable very high frequency (VHF) radiotelephones.

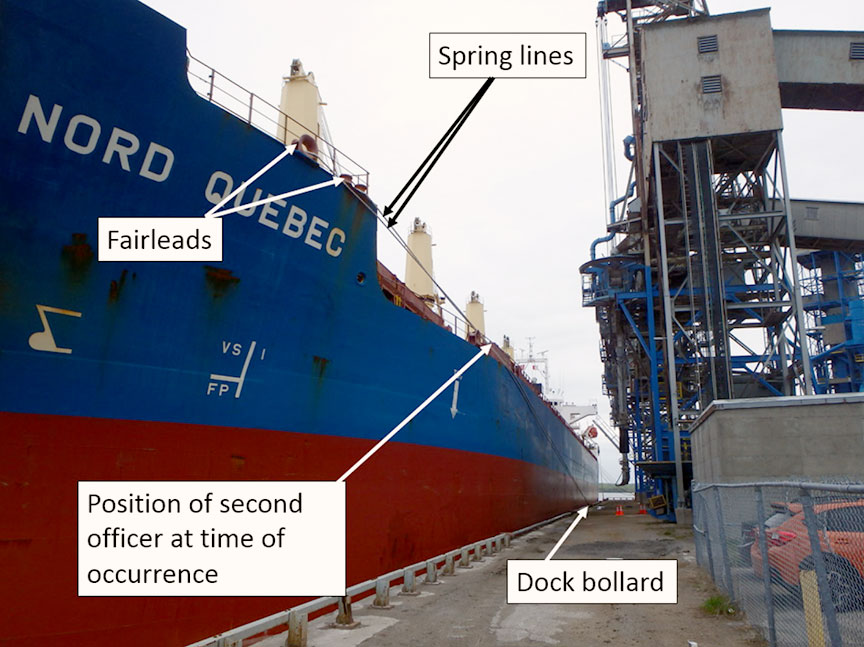

At 1500, the vessel was in final approach and parallel to the berth of section 16; the vessel's speed was further reduced to 0.5 knots and the 2 tugs were ordered to push against the vessel's hull. At 1502, the master ordered the forward mooring party to deploy the 2 spring lines. Given the size of the Nord Quebec and the restricted manoeuvering space in the basin, the bridge team decided to use 2 forward spring lines for safety and redundancy. A team of 4 linesmen was on the dock to handle the forward mooring lines and put them on the bollards, as tasked by the pilot via VHF radiotelephone. At 1505, the first spring line was put ashore and a second spring line was subsequently set on the same dock bollard. Both spring lines were winched by the vessel's port mooring unit, on the inner and outer drums, and were passed through different fairleads on the port bow (Figures 2, 3, and 4).

During their deployment, the 2 spring lines were initially kept loose between the dock and the vessel. At 1509, the pilot informed the master that the Nord Quebec was in position. The main engine was already stopped and the master ordered the second officer to heave on the spring lines to keep the vessel in place. The second officer relayed the order to the bosun and both spring lines were pulled taut with the port mooring unit, stopping the vessel's motion.

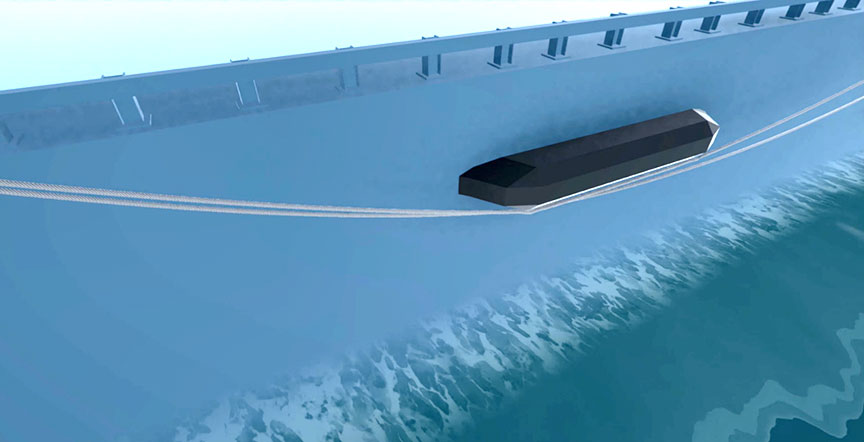

The 2 tugs were continuing to push on the vessel so that it maintained contact with the rubber fenders installed on the dock's side. At this time, both ropes were leading downward from the Nord Quebec's bow fairleads, going horizontally under one of the dock's rubber fenders, and leading upward to the dock bollard.

Figures 5, 6, and 7 offer a close view of the dock's rubber fender, and a depiction of the spring lines caught under the fender. Figures 6 and 7 are still images from an animation that the TSB created to demonstrate the events of this occurrence, and are for illustrative purposes only.Footnote 4

As the spring lines were under increasing tension, the linesmen heard the typical sound of synthetic ropes being stretched. The linesmen noticed that the mooring lines were caught, and were not leading in a straight line from the vessel's fairleads to the dock bollard as they would normally. The linesman carrying the VHF radiotelephone informed the pilot of the situation, who in turn transmitted the information to the master.

At 1512, the master ordered the second officer to resolve the issue and to normalize the layout of the spring lines. Consequently, the second officer, while on the port main deck and leaning over the vessel's side handrail to assess the status of the mooring lines, told the bosun to further heave on the winch to put more tension on the lines.

The pilot ordered the forward tug to stop pushing, which it did at 1513. Nine seconds later, the Nord Quebec's bow started to shift sideways and away from the dock's fenders. One of the linesmen on the dock shouted in English to the second officer to back away from the vessel's handrail. The second officer moved back for a few seconds, but then leaned again over the handrail to look down at the catching point of the spring lines.

At 1514, the 2 spring lines were freed from under the fender and sprung upward in a slingshot motion. The first line went well above the Nord Quebec's side handrail and hit the second officer on the chin. He subsequently fell unconscious on the vessel's main deck.

At 1515, one of the linesmen called 911 and an ambulance was dispatched. The Port Authority's on-duty security guard was informed of the accident at 1519. The ambulance arrived at the port's access gate at 1523 and the security guard activated the opening of the gate 17 seconds later.

Between 1527 and 1550, the local fire brigade, additional paramedics, and police crews arrived on the scene. The second officer was evacuated from the Nord Quebec at 1556, and at 1558 the ambulance left the scene for the local hospital. At 1818, the second officer was pronounced dead.

Environmental conditions

On 22 May, at 1500, the wind in Trois-Rivières, Quebec, was at 4.9 knots from the south-southeast (150°). The air temperature was 12.4 °C and the relative humidity was 88%. The sky was overcast and the visibility was 8.7 nautical miles.

Vessel certification

The Nord Quebec carried all the required certificates for a vessel of its class and for the intended voyage. Its last periodic (annual) inspection was carried out on 11 February 2017 by the flag state's recognized organization.

Personnel experience and certification

The master of the Nord Quebec held a Master Mariner certificate of competency and had sailed as a master on various vessels since 2009. He joined the vessel on 14 May 2017. This was his third contract with the company and his second contract on board the Nord Quebec.

The second officer held an Officer in Charge of a Navigational Watch certificate of competency issued on 21 July 2015. He joined the Nord Quebec in December 2016 and held the 12–4 watch.Footnote 5 The investigation determined that the second officer was not fatigued at the time of the occurrence.Footnote 6 The second officer had obtained a perfect score on a "Maritime English" shore-based course taken in October 2016, and was proficient in spoken English.

The pilot held a Master Mariner certificate of competency and had obtained his Laurentian Pilotage Authority Class A pilot licence in 2010. The 2 apprentices held a Master Mariner certificate of competency and a Master, Near Coastal certificate of competency, respectively. Both apprentices had obtained their Laurentian Pilotage Authority Class D pilot licence in 2016.

Safety during mooring operations

The master and the pilot agreed that the tugs would be made fast at the starboard bow and quarter of the Nord Quebec, and that when the vessel approached with its port side to the dock, the 2 spring lines would be the first lines ashore. When the vessel approached the dock at section 16 in Trois-Rivières, this arrangement was executed as planned.

Vessel safety management system

Chapter 7 of the International Safety Management (ISM) CodeFootnote 7 states that companies

should establish procedures for the preparation of plans and instructions, including checklists as appropriate, for key shipboard operations concerning the safety of the ship and the prevention of pollution. The various tasks involved should be defined and assigned to qualified personnel.Footnote 8The Nord Quebec's safety management system (SMS) addresses these requirements in its chapter on mooring operations.Footnote 9 According to the SMS, the crew is required to ensure that a risk assessment, work instruction, and toolbox meeting are completed before they conduct any mooring operation.Footnote 10

According to a shipboard recording document that was edited and completed on 25 May, a mooring risk assessment had been carried out on the Nord Quebec prior to its berthing on 22 May. This record states that the assessment addressed the risks in mooring operations, including probabilities and types of injuries, as well as the resulting instructions, protections, and preventive measures to undertake. Although the risk assessment did not specifically address the docks of the Port of Trois-Rivières, the document identified, among other generic risks, "[t]he risks of injuries occurring in connection with hawsers that spring up […]."Footnote 11

Following the risk assessment, the mitigation measures put in place were considered to have lowered the initial risk level from serious (level 7) to moderate (level 5).Footnote 12 The document stated that a toolbox meeting was conducted and that the risk assessment and all potential hazards were discussed prior to mooring operations. It also stated, "Informed ECR [engine control room]Footnote 13 and all crew involved." All the required SMS paperwork was completed and signed by the chief officer and the bosun.

Training and familiarization

In October 2016, the second officer successfully completed shore-based training on personal safety and team leadership. He received safety familiarization and training upon joining the Nord Quebec, including the operation of mooring equipment, his job description and responsibilities, and the master and chief officer's standing orders.

The second officer had been on board the vessel for 6 months; he was familiar with the work environment and with all routine working procedures such as mooring operations.

Port authority access policies

The International Ship and Port Facility Security Code (ISPS Code)Footnote 14 is

the basis for a comprehensive mandatory security regime for international shipping. The Code […] outlines detailed maritime and port security-related requirements which […] port authorities […] must adhere to, in order to be in compliance with the Code. […] [T]he Code [also] provides a series of recommendatory guidelines on how to meet the requirements and obligations […].Footnote 15Implementing the provisions of the ISPS Code ensures that adequate and proportionate maritime security measures are in place on board ships and in ports. Port facilities to which Chapter XI-2 of the ISPS Code applies are required to develop and maintain a port facility security plan based on a port facility security assessment. These facilities are also required to designate port facility security officers, who, together with appropriate port facility security personnel, develop and implement measures designed to prevent unauthorized access to the port facility, to vessels moored at the facility, and to restricted areas of the facility.

In Canada, the provisions of the ISPS Code fall under an actFootnote 16 and regulations.Footnote 17 These regulatory requirements apply to the Port of Trois-Rivières,Footnote 18 which must develop and follow a marine facility security plan in consultation with emergency response providers.Footnote 19 Among other requirements, the port authority must monitor and control access to its facilities.

The Port of Trois-Rivières has fenced all boundaries of the areas that fall under the provisions of the Marine Transportation Security Regulations. Remotely operated security gates restrict access to these areas, including the dock of section 16. The access gates are monitored with a closed-circuit camera system and are remotely operated from a nearby reception and security office, which is constantly staffed by a security guard during the day. During the night shift, this guard must periodically conduct security rounds, during which he or she patrols the port facilities in a motor vehicle. If a person requests access to the facilities during those times, an internal communication system allows the person to communicate verbally with the security guard, who must then drive back to the reception and security office to operate the gate and grant access to the port facilities, potentially causing delays. The same protocol applies to all persons, including emergency first responders.

911 emergency call centre

All emergency calls to 911 in the Trois-Rivières area are transferred to a dispatch centre operated by a private company.

Thirty-five seconds after receiving the 911 call from the linesman on the dock beside the Nord Quebec, the dispatcher transferred the call to paramedic services. The dispatcher provided paramedic services with the only address registered in the database for section 16 of the Port of Trois-Rivières: 1545 Du Fleuve Street. This address corresponds to the port authority's administrative offices, located approximately 2 km from the entrance gates to section 16.

Previous occurrences

According to data on mooring accidents compiled by the UK P&I [protection and indemnity] Club over a 20-year period, in 53% of the occurrences, the mooring lines parted; in 42% of the occurrences, mooring lines jumped or slipped off. The remaining 5% of the occurrences were caused by actual equipment failure. Additionally, the UK P&I Club notes that "[w]hilst mooring injuries are the seventh most frequent cause of personal injuries in the Club they are the third most expensive per claim indicating how horrific some of these injuries can become."Footnote 20 Finally, the U.K. P&I Club indicates that 14% of the compiled mooring accidents resulted in death.Footnote 21

Occurrences in Canada

From 2007 to 2017, 24 occurrences (including this occurrence) involving mooring operations in Canada on domestic and foreign-flagged vessels were reported to the TSB. In these occurrences, 24 persons sustained serious injuries and 2 persons were fatally injured. Nine occurrences were caused by mooring lines parting and whipping (also known as "snap-back"), 5 were due to the slingshot and catapult effects of taut mooring lines, and 10 involved crew members falling, tripping, or being crushed during mooring operations.

The following is a summary of occurrences in Canada involving issues with mooring operations.

TSB Marine Occurrence M07C0060 – On 25 September 2007, while tying up to the approach wall of lock 1 in the Welland Canal, Ontario, 2 crew members on board the bulk carrier Canadian Olympic were struck on their heads when a steel mooring wire parted. Both crew members were seriously injured.

TSB Marine Occurrence M08L0153 – On 31 October 2008, a crew member of the bulk carrier Algoisle was fatally injured after being hit by a mooring line while shifting the vessel alongside the dock in Havre-Saint-Pierre, Quebec. Another crew member was seriously injured in the occurrence.

TSB Marine Occurrence M10L0115 – On 26 August 2010, a crew member on board the containership Hanjin Montreal was seriously injured by a parting mooring line while the vessel was berthing in the Port of Montreal, Quebec.

TSB Marine Occurrence M12L0089 – On 18 July 2012, a crew member on board the products/chemical tanker Sarah Desgagnes was seriously injured when a mooring line parted while the vessel was berthing at section 87 in the Port of Québec, Quebec.

TSB Marine Occurrence M14P0088 – On 12 May 2014, a crew member on board the bulk carrier Grand Future was pulled overboard by a mooring line during berthing at Roberts Bank Terminal in Delta, British Columbia. The crew member hit the jetty before falling into the water, sustaining serious injuries.

TSB Marine Occurrence M15C0201 – On 30 November 2015, a crew member on board the bulk carrier Mamry was seriously injured when hit by a parting mooring line while securing the vessel in lock 6 of the Welland Canal, Ontario.

International occurrences

Several occurrences involving complications with mooring, like this occurrence, have been reported internationally.

On 02 March 2015, a crew member on board the liquefied natural gas (LNG) tanker Zarga sustained serious injuries when struck by a parting mooring line during berthing operations at the South Hook LNG terminal in Milford Haven, United Kingdom. Among other findings, the United Kingdom's Marine Accident Investigation Branch determined that the injured crew member had been standing in the snap-back zone of the forward spring lines, the vessel operator and the crew underestimated the risk of snap-back, and the vessel's snap-back assessments did not fully consider all the critical variables, such as the specific mooring lines' characteristics. The investigation determined that a proper snap-back assessment would have made the Zarga's entire forward deck area a snap-back danger zone.Footnote 22

Since 2013, Hong Kong's Marine Accident Investigation and Shipping Security Policy Branch has investigated 4 mooring accidents in which crew sustained fatal injuries. One of these occurrences implicated a foreign-flagged vessel berthing in Hong Kong waters, and the others involved Hong Kong–flagged vessels conducting mooring operations in foreign waters.Footnote 23

On 10 September 2015, the Hong Kong–registered bulk carrier Ocean Gold had its forward spring line caught under a berth fender. When the vessel swung out a short distance from the berth fender, the spring line stretched further, was released from beneath the berth fender, and slingshotted toward a crew member. The spring line struck a crew member on the neck, and the crew member was fatally injured. Among other findings, the investigation determined that the crew member had not been properly reminded to keep away from the dangerous zone created around a taut mooring line during mooring operations.Footnote 24

On 08 March 2013, the Bahamas-flagged cruise ship Norwegian Jade was finalizing its berthing port side to the dock in the port of Katakolo, Peloponnese, Greece, when the forward spring line parted and snapped back toward the mooring platform, striking and pulling a crew member over the guard rails and overboard; the crew member was fatally injured. The Hellenic Bureau for Marine Casualties Investigation determined, among other findings, that the vessel's mooring platforms were not assessed and identified as a snap-back zone. The crew member had therefore been standing in a dangerous area when the occurrence took place.Footnote 25

Between 2007 and 2016, Germany's Federal Bureau of Maritime Casualty Investigation reported on 3 marine casualtiesFootnote 26 where crew members sustained serious injuries, and 2 very serious marine casualtiesFootnote 27 in which crew members received fatal injuries. In all 5 occurrences, vessel mooring lines either broke and snapped back, or became entangled during mooring operations, hitting the crew members.Footnote 28

Between 2010 and 2017, Chile's Marine Accident Investigation and Analysis Division reported on 2 serious marine casualties where crew members sustained serious injuries, and 3 very serious marine casualties in which crew members received fatal injuries. Of these 5 mooring accidents, 4 were caused by mooring lines parting and snapping back, hitting the crew members.

In 2010 and 2012, the Dutch Safety Board investigated 2 mooring accidents that occurred on board Netherlands-flagged vessels, resulting in 2 fatalities and 1 serious injury to a crew member. In both occurrences, mooring lines parted and snapped back, hitting the crew members.Footnote 29 Footnote 30

Between 2007 and 2016, the Swedish Transport Agency reported on 21 mooring operation–related accidents in the country's ports. Of those 21 occurrences, 8 were caused by mooring lines parting and snapping back, 6 by mooring line entrapment, and 7 by an individual tripping, falling, and being struck while conducting mooring operations. One fatality and 20 serious injuries resulted from these mooring accidents.

Analysis

The investigation found that the second officer of the Nord Quebec was fatally injured by one of the 2 spring lines that had been caught under one of the dock's rubber fenders and released during the mooring of the vessel at section 16 of the Port of Trois-Rivières.

Factors leading to the accident

The Nord Quebec was berthing at section 16 of the Port of Trois-Rivières in ballast condition with the assistance of 2 harbour tugs. The second officer was the officer in charge of supervising the forward mooring of the vessel with 3 other crew members, which was sufficient for the intended task. The second officer was not fatigued and had the required qualifications and experience for the intended task. As well, the required pre-berthing risk assessment and toolbox meeting had been conducted with the crew involved. The berthing and mooring plan had been discussed and agreed upon by the master and the pilot.

The plan for mooring the vessel was not uncommon and followed standard seamanship practices: the 2 spring lines were the first lines sent ashore but were initially kept loose, because the vessel was making way at a low speed toward the required position relative to the dock's cargo loading gear. When the pilot determined that the vessel was in position, its residual forward motion had to be stopped. While the 2 tugs maintained the vessel alongside the dock, the spring lines were tensioned to stop the vessel. There was no room between the vessel's hull and the dock fenders for the spring lines to straighten between the vessel's fairleads and the dock's bollard. Consequently, the 2 spring lines became caught under one of the dock's rubber fenders.

As the crew worked to free the 2 spring lines, the second officer leaned over the vessel handrail to visually assess their status, bringing his upper body into the snap-back zone. Although the second officer backed away from the snap-back zone following a verbal warning of the hazard from one of the linesmen, the second officer leaned over the handrail again shortly thereafter. The investigation could not determine why the second officer entered the snap-back zone again.

As the vessel's hull moved away from the rubber fender and the spring lines were freed, the energy stored in their synthetic fibers caused them to snap upward in a slingshot motion along the Nord Quebec's side shell plating. The first spring line went above the main deck handrail, fatally injuring the second officer.

Findings

Findings as to causes and contributing factors

- While the Nord Quebec was mooring at section 16 of the Port of Trois-Rivières with the assistance of 2 tugs, the vessel's 2 spring lines became caught under one of the dock's rubber fenders.

- The second officer leaned over the vessel handrail to visually assess the status of the caught lines, bringing his upper body into the snap-back zone of the spring lines.

- Although the second officer moved out of the snap-back zone following a verbal warning of the hazard from one of the linesmen, the second officer leaned over the vessel handrail again shortly thereafter.

- As the vessel's hull moved away from the rubber fender and the spring lines were freed, the energy stored in their synthetic fibers caused them to snap upward in a slingshot motion along the Nord Quebec's side shell plating.

- The first spring line went above the main deck handrail, fatally injuring the second officer.

Other findings

- The access gates to the Port of Trois-Rivières are periodically unattended at night when the routine security patrols take place, potentially delaying emergency first responders from being able to access the facilities and vessels during those times.

- The address in the 911 dispatch database for the Port of Trois-Rivières was actually for a location 2 km away from the port entrance gates.

Safety action

Safety action taken

Transportation Safety Board of Canada

On 18 January 2018, the TSB sent Marine Safety Information Letter 01/18 to Transport Canada (TC), with a copy to the Maritime and Corporate Administrator of the Republic of the Marshall Islands and to the Marine Accident Investigation Branch of the United Kingdom, sharing various statistics collected by the TSB and other Member States of the International Maritime Organization (IMO). These statistics showed multiple mooring-related marine casualties, which occurred both in Canada and abroad, demonstrating the international profile of the safety issues related to mooring operations on board merchant vessels. The TSB invited TC, as Canada's State Representative to IMO, to bring the information to the IMO's Sub-committee on Ship Design and Construction (SDC), as the latter had been tasked with proposing changes to Chapter II-1, Part A-1, Regulation 3-8 (Towing and mooring equipment) of the International Convention for the Safety of Life at Sea, 1974 (SOLAS), revising the guidelines MSC.1/Circ.1175 (Guidance on shipboard towing and mooring equipment), and drafting new guidelines for safe mooring operations for all ships.

Transport Canada

Following receipt of Marine Safety Information Letter 01/18, TC attended the 5th session of the IMO's SDC Sub-committee, which took place in London, United Kingdom at the end of January 2018. The Canadian delegation prioritized participating in the Working Group (WG) for safe mooring operations, along with 25 other IMO Member States and 13 non-governmental organizations. Subsequently, TC shared with the TSB a summary of the WG's recent activities. Noticeably, the SDC Sub-committee finalized the amendments to Regulation II-1/3-8 of SOLAS. Meanwhile, the WG developed the revised guidelines MSC.1/Circ.1175 and new draft guidelines on the inspection and maintenance of mooring equipment, on the design of mooring arrangements, and on the selection of appropriate mooring equipment and fittings for safe mooring. Furthermore, TC plans to participate in an intersession Correspondence Group to further develop these guidelines, to consider the consequential amendments to other relevant IMO instruments, and to attend the 6th session of the SDC Sub-committee in 2019.

Dampskibsselskabet Norden A/S

Following the occurrence, Dampskibsselskabet Norden A/S immediately sent a safety information letter to all its vessels, and a formal safety bulletin was distributed to the fleet soon after. A company safety campaign focusing on risk assessment, including preparing and implementing a mooring operation risk assessment, was carried out, and this particular occurrence was discussed during the company's 2017 annual officers' seminar. Additionally, the company's on board computer-based training program now includes a specific chapter on mooring.

Singapore Transport Safety Investigation Bureau

Following the occurrence, the Singapore Transport Safety Investigation Bureau issued a safety flyer for the industry, highlighting the presumed causes for this occurrence and advising the industry to note the risk of serious injuries caused by mooring ropes, even without those ropes failing when put under strain.

Administration portuaire de Trois-Rivières

The Trois-Rivières Port Authority had the address for the main entrance gate to its facilities, 132 de la Commune Street, added to the 911 dispatch database for paramedic services and the fire brigade.

This report concludes the Transportation Safety Board of Canada's investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .