Marine transportation safety investigation report M18C0240

Crew member seriously injured

Passenger vessel Amadea

Québec, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content.

-

Table of contents

Summary

On 09 September 2018, a crew member of the passenger vessel Amadea was seriously injured while stowing lifeboat No. 4 after a regular lifeboat drill. At the time of the occurrence, the Amadea was berthed at section No. 21 in the port of Québec, Quebec. The injured crew member was transported to a local hospital by ambulance.

1.0 Factual information

1.1 Particulars of the vessel

| Name of the vessel | Amadea |

|---|---|

| IMO number / Official number | 8913162 / 8001146 |

| Port of registry | Nassau |

| Flag | Bahamas |

| Type | Passenger / Cruise |

| Call sign / MMSI | C6VE9 / 308445000 |

| Classification | LR 100 A1 Passenger Ship, L1, LMC, UMS |

| Gross tonnage | 29008 |

| Length overall / registered | 192.82 m / 172.93 m |

| Breadth extreme / moulded | 27.80 m / 24.7 m |

| Draft loaded / deadweight | 6.718 m / 3939 tonnes |

| Built | 1991 (hull No. 2050), Mitsubishi Heavy Industries Nagasaki Shipyard & Machinery Works Ltd., Nagasaki, Japan. |

| Propulsion | Two 4-stroke medium-speed diesel engines, driving two controllable pitch propellers (Total maximum continuous rating – MCR – 18522 kW). |

| Bow thruster | 1 tunnel-type thruster (1450 kW) |

| Crew on boardat the time of the occurrence | 318 |

| Passengers on board at the time of the occurrence | 558 |

| Registered owner | MS Amadea Shipping Ltd., Nassau, Bahamas. |

| Technical manager | Bernhard Schulte Cruise Services GmbH & Co. KG, Hamburg, Germany. |

1.2 Description of the vessel

The Amadea (Figure 1) is a deep-sea cruise ship built in 1991 in Japan. The vessel can accommodate a complement of 904 persons. The vessel is fitted with a public address (PA) system throughout all crew and passenger areas, with microphones positioned on the bridge, at reception, and in the back office. The vessel has a shipboard hospital.

The Amadea has 6 partially-enclosed motor lifeboats,Footnote 1 which are situated 3 per side on deck No. 7. The lifeboats are launched via twin-arm gravity davits, and secured with on- or off-load release mechanisms. Lifeboats No. 1 and No. 2 are also certified as rescue boats, while lifeboats No. 3, No. 4, No. 5, and No. 6 also serve as tender boats.Footnote 2 Lifeboat No. 4 is located on the port side, abeam of the vessel’s funnel, between frames No. 42 and No. 56; the lifeboat is 11.5 m long and can carry 132 people (Appendix A).

1.3 Lifeboat No. 4

The Amadea’s lifeboats No. 3 and No. 4 are identical, with identical winches and davits. The lifeboats were manufactured by Harding Safety A/S of Norway.Footnote 3 When used as tender boats, each has a maximum capacity of 90 people.

1.3.1 Lifeboat No. 4 davit and winch

Lifeboat No. 4’s davit was manufactured by D-I Davit International GmbH of GermanyFootnote 4 and has powered lowering capability in addition to gravity lowering. The D-I Davit International GmbH instruction manual on board the Amadea at the time of the occurrence referred to a winch system; section 2.7 of this manual states that “for craft recovery by manual cranking, the [winch] is back-kick proof.”Footnote 5 The Amadea had been originally fitted with lifeboat davit winches manufactured by D-I Davit International GmbH; however, at the time of the occurrence, none of Amadea’s lifeboat davits were so fitted.

The original davit winches on board the Amadea were replaced in 2000 with winches manufactured by Sekigahara Seisakusho Ltd of Japan.Footnote 6 The davit winches for lifeboats No. 1, No. 2, No. 5, and No. 6 are of different types than the davit winches for lifeboats No. 3 and No. 4. The davit winches for lifeboats No. 3 and No. 4 are a dual-drum steel winchFootnote 7 that can be driven by either an electrical induction motor,Footnote 8 or manually operated by a removable crank handle. The winch motor has an enclosed, normally-engaged, spring actuated 90 V direct-current electromagnetic brake coupled to its free end. This electromagnetic brake releases when the motor is energized. The winch gearbox has a mechanical ratio of 239:1.

No. 3 and 4 davits are fitted with twin-arms that are paired with a single winch. Each davit arm has an adjustable lever-operated electromechanical limit switch that interrupts the winch motor’s power supply once each davit arm approaches its uppermost position, immediately before contacting its stop, during lifeboat stowage (Figure 2 and Appendix C).

While at sea, gripes ensure that the lifeboats remain in their stowed positions. In addition to the gripes, 2 harbour pins can be inserted in holes that are aligned on each davit arm and the davit frame, to lock the lifeboats in their stowed position while the vessel is in port or during maintenance (Figure 2).

1.3.2 Lifeboat No. 4 davit winch motor electromagnetic brake instruction manual

The Sekigahara Seisakusho Ltd. winch motor electromagnetic brake instruction manual describes lifeboat No. 3 and No. 4’s winch motor electromagnetic brake, as well as its operation and how to adjust it. The manual includes the following danger and warning notes:

Danger: The case of the possibility that actual users will be dead or injured seriously if they operate the motor incorrectly.

Warning: The case of the possibility that actual users will be injured or the material damage occurred only if they operate the motor incorrectly.Footnote 9

There are several danger notes found in the manual for the safe operation of the winch, including:

- “Danger: Please never fail to operate while manual releasing.”Footnote 10

- “Danger: Please never operate it at the speed exceeding limit revolution.”Footnote 11

The manual also provides maintenance and inspections specifications for the winch and brake. The manual includes basic lifeboat launching and recovery procedures, but does not include any instruction for manual winching using the winch crank handle.Footnote 12 The manual does not specify that the winch is kickback proof.

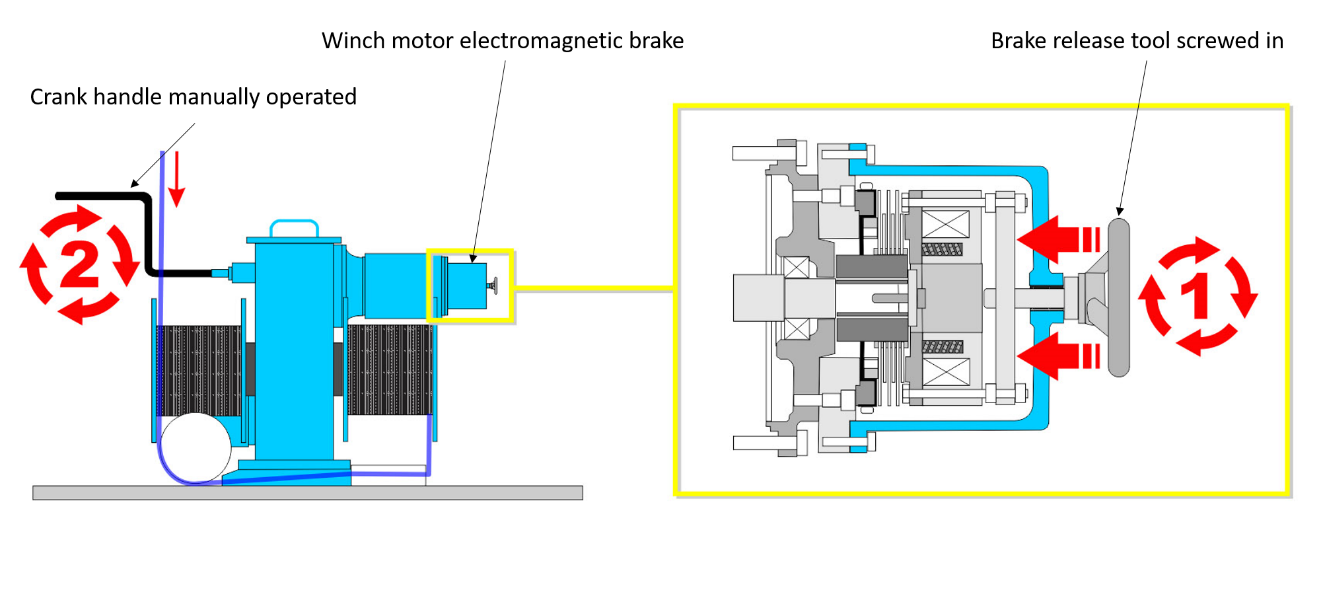

The electromagnetic brake is manually released using a tool consisting of a small-radius hand wheel attached to a threaded rod (Figure 3). The brake release tool is screwed into the brake casing at the free end of the winch motor, partially compressing the electromagnetic brake’s spring. The winch instruction manual warns that the brake release tool is the only tool that should be used, that the tool must be turned only by hand, and that using “extreme power”Footnote 13 could damage the internal components of the electromagnetic brake.

1.3.3 Lifeboat No. 4 launching, recovery, and stowage

The winch for lifeboat No. 4 has 3 separate brakes to control the davit. By default, the primary hand brake is engaged and must be released by an operator who lifts and holds up a weighted control handle. The 2nd brake is a centrifugal governor brake that controls the lifeboat’s rate of descentFootnote 14 and engages when the primary brake is released and the winch is paying out. The 3rd brake is the motor electromagnetic brake, which allows the motor to fully engage without slippage during lifeboat descent and ascent. The electromagnetic brake must be manually released using the brake release tool, during the manual winching stage for stowage and securement.

The winch is used to launch and retrieve lifeboat No. 4 (Figure 4). To retrieve the lifeboat, it must first be secured to the davit wire falls’ on- or off-load release mechanism.

The operator pushes the winch control buttons to energize the winch motor. The winch drums turn to pull and coil up the wire falls, which lifts the lifeboat (Figure 5).

The lifeboat is raised until it comes in contact with the davit arms. The winch continues to pull both the lifeboat and the davit arms inboard, rolling them along each davit arm’s roller tracks (Figure 6).

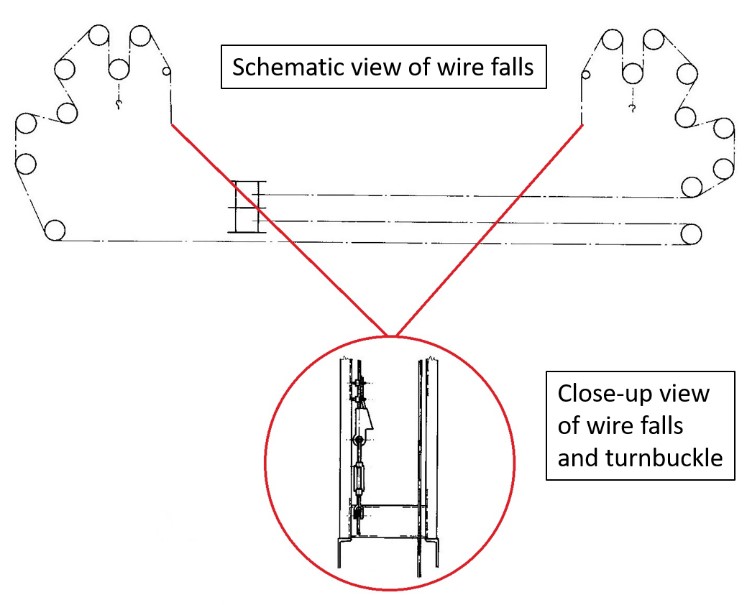

The fixed end of the wire falls of the Amadea’s lifeboat davits is fitted with a turnbuckle so that adjustments can be made to ensure that the davit arms remain aligned while they are moving (Appendix D). Overloading of the wire falls and damage to the mechanical components of the davit (Figure 2, Figure 7, and Appendix C) is prevented by means of an electromechanical limit switch to each davit arm.

Both electromechanical limit switches are adjustable, and their levers can be repositioned to vary the point at which the winch motor de-energizes before the davit arms reach their stops. At the time of the occurrence, the switches were adjusted so that the winch motor would de-energize 20 cm before the davit arm reached its stop.

Operators must then secure the lifeboat by manually winching it up to its final stowed position. To facilitate manual winching, the electromagnetic brake is manually disengaged using the brake release tool, which is screwed into the winch motor (Figure 8, Step 1), and the crank handle is installed to its coupling on the winch gearbox and turned by hand (Figure 8, Step 2).

Once operators winch the lifeboat to its final stowed position, they secure the lifeboat with gripes. At this point, the holes in the davit arms and davit framed are aligned and the harbour pins can be inserted while the vessel is in port or during maintenance, to further secure the arrangement (Figure 9). The electromagnetic brake is still overridden in this situation, because the winch is being operated manually.

1.4 History of the occurrence

On 01 July 2018, MS Amadea Shipping Ltd contracted Bernhard Schulte Cruise Services to take over the technical management of the Amadea from V Ships Leisure S.A.M.

On 09 September 2018 at 0838,Footnote 15 the Amadea berthed at section No. 21 of the port of Québec, Quebec, with its starboard side to the dock (Appendix B). At 1030, using the vessel’s PA system, the master ordered the crew to begin its mandatory weekly fire drill, immediately followed by its mandatory weekly vessel abandon (lifeboat) drill.Footnote 16

Per the vessel’s muster list,Footnote 17 during the fire drill the boatswain (bosun) and 3 other crew members prepared the starboard lifeboats for launching, while a similar team led by the assistant bosun prepared the port-side lifeboats; the vessel’s first officer was in charge of supervising both teams. During the drill, the first officer, bosun, and assistant bosun communicated with each other and with the safety officer using ultra-high frequency (UHF) portable radiotelephones. The safety officer then transmitted any pertinent information to the staff captain.

At 1102, once the fire drill was complete, the staff captain used the PA system to order the crew to begin the vessel abandon drill. By that time, all lifeboats had been readied for launch, so the staff captain gave the command to lower lifeboats No. 2, No. 4, and No. 6 to the embarkation level (deck No. 7).Footnote 18 At 1105, crew members informed the staff captain that all 3 port lifeboats had been lowered to the embarkation level.

At 1106, the staff captain used the PA system to order the end of all drills and instructed the bosun to oversee the proper stowage of all lifeboats. In the following minutes, ordinary seamen (OS) and able seamen (AB) began securing the lifeboats. Some crew members were wearing protective headgear, and others were not. While the lifeboats were being secured, the staff captain, safety officer, and all the emergency party leaders met on the bridge for a post-drills debriefing.

Around 1119, the bosun, the assistant bosun, 2 OS, and 1 AB recovered lifeboat No. 4 using its electrically driven davit winch. The lifeboat was brought inboard almost to its stowed position when the winch motor was deactivated by one of the 2 electromechanical limit switches.

Two minutes later, the winch crank handle was installed to its coupling on the winch gearbox, and the bosun disengaged the electromagnetic brake. An OS and an AB, positioned face-to-face on either side of the crank handle, began to manually winch the lifeboat to its final stowed position.

After a few minutes of manually winching, the OS became exhausted and another OS took his place. The relief OS was not wearing protective headgear. By approximately 1129, the forward davit arm had reached its stowed position and the assistant bosun inserted the harbour pin into the davit arm. The relief OS and the AB continued to manually crank the winch to bring the aft davit arm into its stowed position.

About a minute later, the relief OS and the AB lost their grip on the crank handle. The crank handle kicked back and freewheeled in a counter-clockwise rotation, hitting the relief OS on the head and knocking him unconscious. The davit’s aft arm lowered uncontrollably and the lifeboat’s stern lowered with it, eventually coming to a stop (Figure 10).

At 1131, the bosun reported the accident to the safety officer using his UHF radiotelephone. Shortly after, the staff captain used the PA system to inform the crew that there was a medical emergency, and to deploy the response party to the scene. At approximately 1133, the vessel’s medical party arrived at lifeboat station No. 4 and administered first aid to the OS; he was subsequently brought to the Amadea’s shipboard hospital.

At 1133, the staff captain called the Canadian Coast Guard’s Marine Communication and Traffic Services (MCTS) in Québec using a very high frequency (VHF) radiotelephone (VHF channel 12) to request an ambulance. MCTS dispatched first responders and, at 1153, an ambulance arrived at the Amadea’s dock. Paramedics boarded the vessel, and at around 1220 the OS, who had sustained a serious head injury, was evacuated and transported to a local hospital.

1.5 Vessel damage

Following the uncontrolled lowering of lifeboat No. 4‘s aft davit arm, one of the arm’s roller tracks was bent close to the shipside handrail (Figure 11).

1.6 Injuries to personnel

After being hit by the winch crank handle, the OS remained unconscious for a few seconds and suffered retrograde amnesia when he regained consciousness. He was diagnosed with a mild traumatic brain injury with intracranial hemorrhage, a fracture of the left temporal bone, and small lacerations and epidural hematomas in the left temporal and occipital regions of the head. The OS was prescribed 14 days of rest and was discharged from the vessel.

1.7 Environmental conditions

At the time of the occurrence, the sky was clear and the visibility was 12 nautical miles (NM). The wind was at 2 knots from the northwest. The air temperature was 16 °C, and the water temperature was 7 °C. The deck surrounding lifeboat station No. 4 and its equipment were dry and well lit.

1.8 Vessel certification

The Amadea carried all the required certificates for a vessel of its class and for its intended voyage. The flag state’s recognized organization (RO) carried out the vessel’s class-renewal survey on 20 December 2015, and the vessel’s last periodic survey (annual) was conducted on 27 October 2017.

The vessel’s lifeboats, davits, and winches were type approved and properly certified. Their periodic maintenance was carried out in accordance with all applicable requirements by both the crew and shoreside service providers. The company that performed periodic maintenance on the davits for the Amadea’s lifeboats is a shoreside service provider that is approved by the vessel’s RO but was not approved by the davit manufacturer.

1.9 Personnel certification and experience

The master of the Amadea held a Deck Officer Class 1, Master Mariner certificate of competencyFootnote 19 and joined the vessel on 25 July 2018.

The staff captain held a Master certificate of competencyFootnote 20 and joined the Amadea on 08 August 2018.

The safety officer held a Deep Sea Captain certificate of competencyFootnote 21 and had been sailing as a safety officer on passenger vessels since 2008. He joined the Amadea on 17 July 2018.

The bosun started his marine career in 1985. He had been employed as bosun on the Amadea since 2013. He most recently joined the vessel on 26 May 2018.

The assistant bosun had started working on board the Amadea in 2010, and most recently joined the vessel on 08 March 2018.

The AB had been working on the Amadea since 2016. He most recently joined the vessel on 08 March 2018.

The relief OS held a rating as able seafarer deck certificate of proficiencyFootnote 22 issued on 11 January 2017 in Indonesia. He joined the Amadea on 25 July 2018, and had not worked on the vessel previously.

1.10 Safety management

1.10.1 International Safety Management Code

The purpose of the International Safety Management (ISM) CodeFootnote 23 “is to provide an international standard for the safe management and operation of ships and for pollution prevention.”Footnote 24 The objectives of the Code are “to ensure safety at sea, prevention of human injury or loss of life, and avoidance of damage to the environment, in particular, to the marine environment, and to property.”Footnote 25

To this effect, the ISM Code requires companies to

establish procedures, plans and instructions, including checklists as appropriate, for key shipboard operations concerning the safety of the personnel, ship and protection of the environment. The various tasks should be defined and assigned to qualified personnel.Footnote 26

Concerning the training of new crew members, the ISM Code stipulates that

[t]he [c]ompany should establish procedures to ensure that new personnel and personnel transferred to new assignments related to safety and protection of the environment are given proper familiarization with their duties. Instructions which are essential to be provided prior to sailing should be identified, documented and given.Footnote 27

A risk assessment is a means to identify potential hazards. During this assessment, hazards and the probability of their occurrence are identified, and the severity of their potential adverse consequences are evaluated. From this assessment, appropriate mitigation measures can be put into place to eliminate the risks or reduce them as much as possible. Appropriate mitigating measures may include procedures for crew members to follow when carrying out critical shipboard tasks and operations.

In February 2018, Bernhard Schulte Cruise Services was issued a document of compliance (DOC) by an RO as proof of compliance with the ISM Code. On 01 July 2018, the Amadea was issued a safety management certificate by another RO as proof of compliance with the ISM Code.

At the time of the occurrence, Bernhard Schulte Cruise Services had not conducted a formal risk assessment regarding the retrieval and stowage of lifeboats No. 3 and No. 4, and had not identified potential hazards for these operations. There was no written operational procedure for the recovery of lifeboats No. 3 and No. 4 on board the Amadea.

1.10.2 Crew training and familiarization

As people learn a new role, their competence will develop along a continuum from novice to not-yet-competent, to proficient, and then to expert. In moving across this continuum, learners proceed through a series of predictable stages. When a minimal level of competence is attained, they can be described as being consciously competent, or at a stage where tasks may be performed effectively. As they become proficient or expert, tasks become more automatic.Footnote 28 With practice, they are able to anticipate outcomes of tasks with increasing accuracy, and the conduct of tasks become more precise.Footnote 29

Crew training and practice, such as familiarization and drills, are factors that influence the effectiveness of shipboard operations. As part of its safety management system (SMS), the Amadea had established a structured training system for the crew. The company’s SOLAS-compulsory fire safety and lifesaving appliances training manuals were also made available for all crew to consult as required.Footnote 30

On board the Amadea, new crew members received training before being assigned duties. The training program for new crew members consisted of 6 field training modules:

- Safety familiarization training: before being assigned shipboard duties, all persons employed or engaged on a seagoing vessel other than passengers shall receive approved familiarization training or sufficient information and instruction in personal survival techniques. Familiarization training also includes the operation of watertight doors.

- Induction 1 (within 3 days of embarkation): review of safety familiarization training; theory, demonstration and practice concerning fire hoses, extinguishers and fire blankets (an expansion on response to fire with hoses, extinguishers, fire blankets and other firefighting appliances).

- Induction 2 (within 5 days of embarkation): designated roles and actions of crew members in case of abandonment; hypothermia; lifeboat preparation, launching operation, and equipment; davit and throw-over inflatable life raft preparation, launching, operation and equipment.

- Induction 3 (within 7 days of embarkation): ISM; SMS; company policies; use of personal protective equipment (PPE), its location, fault reporting, and Company Policy; International Ship and Port Facility Security (ISPS) Code; test of crew knowledge and capability following familiarization.

- Induction 4 (within 14 days of embarkation): exercise in lifeboat operation.

- Induction 5 (within 14 days of embarkation): first aid and cardiopulmonary resuscitation; survival first aid; precautions for sexually transmitted infections; shipboard health; norovirus; verbal assessment.Footnote 31

Induction 2 covered lifeboat launching only in cases of abandonment of the vessel; no training was provided on lifeboat recovery.

According to the Amadea’s training and drill records, all crew members were familiarized and trained in accordance with the vessel’s training program, as required by the vessel’s SMS and Bernhard Schulte Cruise Services’ policies. However, based on these shipboard records, the relief OS had never practised recovering lifeboat No. 4 before the occurrence.

1.10.3 Personal protective equipment

When operating lifeboat winches and davits, and when using lashings, crew members need to wear proper personal protective equipment (PPE). This equipment includes protective headgear, gloves, and safety shoes. When worn properly, protective headgear such as hard hats protect a person’s head from impact and penetration from falling or flying objects. Social factors, such as how a work group perceives the wearing of PPE, may influence an individual’s decision to use the equipment. Training and awareness can enhance peer acceptance of PPE use, and some studiesFootnote 32 have shown that direct incentives can increase its use.

Each deck crew member on the Amadea was issued their own PPE, such as protective headgear, coveralls, safety shoes, gloves, and safety glasses, and kept it in their cabin.

1.10.4 Supervision

Supervision is an administrative control that supports or reinforces human factors aspects including compliance with procedures, priorities, workload, fatigue, engagement and motivation. Supervisors can have a significant impact on many of the factors that influence employee behaviours in the workplace. Footnote 33

Individuals in any form of supervisory role need to be competent and trained to supervise. Competence includes both technical and non-technical skills such as planning, communication, and delegation. Technical competence should also include an understanding of risks and mitigation measures. The most effective leaders are those who consciously establish a command hierarchy that is appropriate to the qualifications and experience levels of its team members.

During the occurrence, the relief OS was not wearing his protective headgear and was not instructed by senior crew members to wear it during lifeboat recovery and stowage operations.

1.11 Post-occurrence examination and engineering analysis

Following the occurrence, the TSB examined lifeboat No. 4’s davit winch arrangement, and conducted function tests on and an internal inspection of the gearbox and electromagnetic brake. During the TSB’s examination, lifeboat No. 4 was prepared, launched, and recovered several times in the same manner as during the occurrence. The primary hand brake, centrifugal governor brake, and electromagnetic brake were tested, and they performed as intended. The primary hand brake released the lifeboat and stopped its descent effectively; the centrifugal governor brake ensured that the descent rate was controlled; the electromagnetic brake allowed the winch motor to fully engage without slippage during ascent and descent movements, and it disengaged when the brake release tool was applied. Final manual winching to the stowed position was accomplished with just 1 operator.

Two shortcomings were observed during testing:

- The electromechanical limit switches, installed to stop the winch motor before the davit arms reached the stops, were out of adjustment such that the winch stopped before clearing the harbour pin holes. This necessitated additional manual winching before the davit arms reached the final stowage position.

- The davit arms were slightly misaligned, such that the fore arm contacted its stop before the aft arm. The operator had to continue manual winching to bring the aft davit arm to its stop, which created tension in the davit falls. The investigation could not determine for how long the davit arms had been misaligned prior to the occurrence, or why the misalignment was not corrected using the wire falls’ turnbuckles.

During testing, close attention was paid to the feedback forceFootnote 34 of the winch’s manual crank handle during the various stages of lifeboat deployment. Throughout the various stages of deployment, operators stopped the electrically controlled movement, manually released the electromagnetic brake, and operated the manual crank handle. The crank handle gave little to no feedback when the lifeboat was in any of the following stages:

- waterborne

- slight tension on the wire falls

- just above the water

- half way up

- davit engagement

- davit arms at 45 degrees

- davit arms retracted

If the operator stopped turning the manual crank handle, it would remain motionless. If the operator pushed and released the manual crank handle, it would slowly re-wind. A single operator could maintain full control of the manual crank handle with little effort.

The tests and subsequent analysis revealed that, if operated correctly, the whole system worked as designed. However, if the manual winching continued after the davit arms contacted their stops, feedback in the manual crank handle increased dramatically as elastic stress in the cabling and framework increased. With the winch gearbox mechanical ratio of 239:1, continued manual winching created additional tension in the system with little additional effort. The tests identified that if the manual crank handle is fitted to its shaft on the winch gearbox, this excessive tension could cause a sudden backlash where the crank handle forcefully rotates at high speed.

During the lifeboat stowage trials, the TSB observed that the crew used a lever-type toolFootnote 35 in the spokes of the electromagnetic brake release tool’s hand wheel to create additional torque when releasing the electromagnetic brake. Using this lever on the hand wheel allowed crew members to disengage the electromagnetic brake further than what would normally be accomplished by hand alone, because some drag within the electromagnetic brake is required to prevent or control backlash in the system. Using the lever-type tool was routine practice, including during the occurrence.

The TSB examination and engineering analysis concluded that the winch and davit system for lifeboat No. 4 worked safely when operated as intended, but could create an unsafe condition when not rigged and operated correctly. With the electromechanical limit switches positioned to stop the winch motor 20 cm away from the stops of the davit arms and with the 2 davit arms being misaligned, extensive manual winching was required to bring the lifeboat to its stowed position.

1.12 TSB laboratory reports

The TSB completed the following laboratory report in support of this investigation:

- LP013/2019 – Functional Testing of Lifeboat No. 4 Winch

2.0 Analysis

This section will discuss the lack of formal operating procedures for lifeboat recovery and stowage on board the Amadea, issues regarding crew familiarization with the vessel’s lifeboat davit and winch systems, the crew’s use of personal protective equipment, supervision by senior crew members, and the failsafe design of lifeboat No. 4’s davit winch.

2.1 Causes and contributing factors to crew member’s injuries

After successfully completing routine fire and lifeboat drills, the Amadea’s crew members were in the process of retrieving and storing the fire fighting appliances and lifeboats that had been deployed as part of the drills. The bosun had been tasked with overseeing the proper stowage of the lifeboats, and was assisted by other deck crew.

The crew members retrieving lifeboat No. 4 used the electrically driven davit winch to raise the lifeboat until the davit arms reached their electromechanical limit switches, which deactivated the winch motor’s power supply. The electromechanical limit switches, with their positions set at 20 cm before the davit arms reached their stops, required extensive additional manual winching to complete the stowage of lifeboat No. 4 following the lifeboat drill. An ordinary seaman (OS) and an able seaman (AB) then installed a manual crank handle on the winch and proceeded to manually winch the lifeboat to its stowed position. The bosun released the electromagnetic brake using the brake release tool to permit manual winching.

The lifeboat falls were not of equal lengths and as a result, the fore davit arm contacted its stop before the aft davit arm. The crew members had to continue manual winching to bring the lifeboat to its stowed position, which put increased tension on the winch system, making manual winching more difficult.

To make manual winching easier, the bosun used a lever-type tool in the spokes of the brake release hand wheel to increase leverage resulting in greater disengagement of the electromagnetic brake, and eliminating the drag that would normally be present in the brake system.

As the OS and the AB continued manually winching to bring the aft arm to its stop, the tension increased on the winch system, making winching more difficult. Eventually, the OS became exhausted from exertion and was replaced by another OS.

The relief OS and the AB continued manual winching and the excessive tension on the winch system caused them to let go of the crank handle. Because the electromagnetic brake was released, the crank handle suddenly kicked back and spun backwards, hitting the OS on the head. The OS was not wearing protective headgear and sustained serious head injuries.

2.2 Design of lifeboat davit winch

Per its original design, the electromagnetic brake is meant to retain some drag when it is manually released, to prevent or control backlash in the winch system as lifeboat No. 4 is manually winched and stowed. To that effect, the electromagnetic brake release tool consists of a small-radius hand wheel, which prevents operators from completely compressing the electromagnetic brake’s internal spring when screwing in the brake release tool by hand. Sekigahara Seisakusho Ltd’s instruction manual warned operators to tighten the brake release tool by hand only, and to not overtighten it.

The electromechanical limit switches were set at 20 cm before the davit arms reached their stops. Additionally, the fore and aft davit arms were misaligned from one another. Consequently, to bring the lifeboat to its final stowed position crew members had to manually winch extensively, due to the winch gearbox ratio of 239:1.

The level of effort required for the additional manual winching was likely what prompted the crew members to further release the electromagnetic brake with a lever-type tool (wheel spanner or F-key), and to have 2 crew members operate the winch crank handle. These actions reduced the drag on the winch crank handle and reduced the amount of effort required to winch the lifeboat. However, these actions had 2 unintended consequences. First, further releasing the electromagnetic brake disabled the drag and overrode the winch’s kickback protection. Second, continued manual winching to align the davit arms after the fore davit arm reached its stop, with 2 crew members on the crank handle, created excessive tension on the winch system.

Bernhard Schulte Cruise Services did not have written procedures or instructions for disengaging the electromagnetic brake, and there was no formal guidance prohibiting the use of a wheel spanner on the brake release tool to disengage the electromagnetic brake.

It became an informal practice among crew members to manually over-torque the electromagnetic brake release tool to reduce the physical effort involved in manually winching lifeboat No. 4. This would result in the winch’s gear train freewheeling if the operator(s) let go of the crank handle. The crew members were unaware of the hazard related to over-torqueing the brake release tool.

If equipment design allows operators to override or disable its built-in safety features, these features will not function as intended, increasing the risk that the crew will be injured while operating this equipment.

2.3 Risk management

Effective safety management requires an organization to have processes and procedures in place to identify hazards and mitigate risks. Formal risk assessments and continuous improvement protocols are designed to accurately capture how a process is being done, identify potential gaps in the process, and proactively address those gaps. Identifying gaps in a process also identifies risks and safety hazards, and proactively addressing those gaps includes taking measures to mitigate those risks and safety hazards. Additionally, the International Safety Management (ISM) Code requires that vessel operators (crew and management) identify risks and establish procedures for all critical shipboard operations, such as the launching and recovery of lifeboats.

Although Sekigahara Seisakusho Ltd’s instruction manual did not make it clear to operators that the davit winch system was not kickback proof, operators were warned that there was a risk of death or serious injury if they operated the motor incorrectly, and that excessive tightening of the electromagnetic brake release tool could damage the unit.

Bernard Schulte Cruise Services did not identify lifeboat recovery (including davit winch operations) as a critical shipboard operation, and therefore did not conduct a risk assessment for this operation. The company also did not identify and mitigate any risks introduced by using 3 different types of davit winches on board a single vessel.

Without having identified any risks associated with lifeboat recovery, no formal procedure for this operation was developed and put in place. The risk of the winch crank handle kicking back was also not identified; therefore, no measures were taken to ensure that crew members were aware of the kickback hazard, and that they should take necessary safety precautions.

Frequently, lifeboat davits and winches on board a vessel are supplied by the same manufacturer, and so generally a manufacturer’s manual provides instructions for both pieces of equipment. As originally fitted, the Amadea’s davits and associated winches were manufactured by D-I Davit International GmbH; however, these winches were retrofitted in 2000 with winches manufactured by Sekigahara Seisakusho Ltd. Consequently, 2 different manuals regarding lifeboat davit winch technical specifications and operations were on board the vessel at the time of the occurrence.

The manual provided by D-I Davit International GmbH included instructions for operating its davits and winches, even though the winches on board the Amadea had been retrofitted with those manufactured by Sekigahara Seisakusho Ltd. Therefore, the sections in the D-I Davit International GmbH manual concerning its winches, and the fact that these winches were kickback proof, no longer applied to the winches on board the vessel. Relying on this manual in lieu of the manual supplied by the shipboard winch manufacturer may have led the officers and crew to believe that there was no risk of the winch crank handle kicking back, and may have prevented the crew from mitigating this risk.

Using personnel protective equipment (PPE) can help mitigate safety hazards and is considered the last line of defense for crew members. It is up to vessel management to determine if a risk is present and if PPE should be worn by crew members. Modifying crew member behaviour with training, oversight, and feedback can enhance PPE use, and using PPE in combination with other risk mitigating measures can further reduce the likelihood of injury.

If the safety hazards associated with critical shipboard operations, such as the launching and recovery of lifeboats, are not identified and mitigated, there is a risk of injury to crew.

2.4 Familiarization and training

The International Convention for the Safety of Life at Sea, 1974 (SOLAS Convention) and the ISM Code require that crew members be properly trained to be familiar with the safe operation of all shipboard equipment that they will use. Safe work methods, including operating procedures and training, need to be developed and adopted to give crew members the necessary guidance and skills to safely carry out operations. Operating procedures and training also provide crew members with a valuable opportunity to assess risks and incorporate mitigating measures.

Vessel management must ensure that new or returning crew members undergo all necessary training and familiarization as soon as possible. Bernhard Schulte Cruise Services had put in place an ISM-compliant safety management system (SMS). The vessel’s SMS included training all crew members on the proper use of PPE such as protective headgear. Although the SMS included training on the launching and operation of the lifeboats, it did not include training on lifeboat recovery and stowage, or on operating the davit winches.

At the time of the occurrence, the relief OS had been on board the Amadea for a month and had taken all the vessel’s basic safety training and familiarization. The OS had also been issued his own protective headgear and trained on how to use it. The OS had never worked on the Amadea before, had limited experience as a seafarer, and did not have any experience with operating a davit winch or with stowage procedures for lifeboats.

Bernhard Schulte Cruise Services began managing the Amadea 2 months prior to the occurrence. Most of the crew members on board the vessel at time of the occurrence had completed several contracts on board with the vessel’s previous managing company, V Ships Leisure S.A.M. The deck ratings and officers were well aware of the lifeboat stowage procedure, including manual winching using the crank handle. Experienced crew members who supervised and worked with the OS did not mention the particulars of the manual winching procedure or the need to wear appropriate PPE for this operation. The relief OS was therefore assisting the bosun in this occurrence without having been trained and familiarized with the task and he was unaware of the risks and hazards associated with it. None of the crew members had been trained and familiarized on the proper operation of the davit winch.

If crew members are not trained in the safe operation of critical shipboard equipment such as lifesaving appliances, there is a risk that they will not operate such equipment in a safe manner.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- The electromechanical limit switches, with their positions set at 20 cm before the davit arms reached their stops, required extensive additional manual winching to complete the stowage of lifeboat No. 4 following the lifeboat drill.

- The lifeboat falls were not of equal lengths and as a result the fore davit arm contacted its stop before the aft davit arm.

- The crew members had to continue manual winching to bring the lifeboat to its stowed position which put increased tension on the winch system, making manual winching more difficult.

- To make manual winching easier, the bosun used a lever-type tool in the spokes of the brake release hand wheel to increase leverage resulting in greater disengagement of the electromagnetic brake, and eliminating the drag that would normally be present in the brake system.

- The relief ordinary seaman and able seaman continued manual winching and the excessive tension on the winch system caused them to let go of the crank handle. Because the electromagnetic brake was released, the crank handle suddenly kicked back and spun backwards, hitting the ordinary seaman on the head.

- The ordinary seaman was not wearing protective headgear, and sustained serious head injuries.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If equipment design allows operators to override or disable its built-in safety features, these features will not function as intended, increasing the risk that the crew will be injured while operating this equipment.

- If the safety hazards associated with critical shipboard operations, such as the launching and recovery of lifeboats, are not identified and mitigated, there is a risk of injury to crew.

- If crew members are not trained in the safe operation of critical shipboard equipment such as lifesaving appliances, there is a risk that they will not operate such equipment in a safe manner.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

- The fixed end of the wire falls of the Amadea’s lifeboat davits is fitted with a turnbuckle so adjustments can be made to ensure that when moving the davit arms remain aligned.

- Both electromechanical limit switches of the Amadea’s lifeboat davits are adjustable, and their levers can be repositioned to vary the winch motor de-energizing distance between the davit arms and their stops.

- The company that performed periodic maintenance on the Amadea’s lifeboats’ davits is a shoreside service provider that is approved by the vessel’s Recognized Organization but was not approved by the davit manufacturer.

4.0 Safety action

4.1 Safety action taken

4.1.1 Bernhard Schulte Cruise Services GmbH & Co. KG

Following the occurrence, Bernhard Schulte Cruise Services ordered a complete inspection of lifeboat No. 4’s davit and winch by a shore technician. This inspection took place on 22 October 2018, while the Amadea was dry docked in Hamburg, Germany. No defect was noted during this inspection.

Bernhard Schulte Cruise Services conducted an internal investigation into this occurrence. The internal investigation concluded that the incident occurred due to human error, that the ordinary seaman was injured because he was not wearing the proper personal protective equipment required for the job, and that the ordinary seaman had not been trained in lifeboat recovery.

Bernhard Schulte Cruise Services has since updated the Amadea’s training manual. For lifeboat recovery, the updated training manual specifies that crew members must wear protective headgear (helmet), gloves, and safety shoes while performing any activity involving lifeboat winches, davits, and lashings. A detailed written procedure involving 4 crew members was implemented for lifeboat stowage.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .

Appendices

Appendix A – Location of lifesaving appliances on board the Amadea

Source: Bernhard Schulte Cruise Services GmbH & Co. KG, with TSB annotations

Appendix B – Area of the occurrence

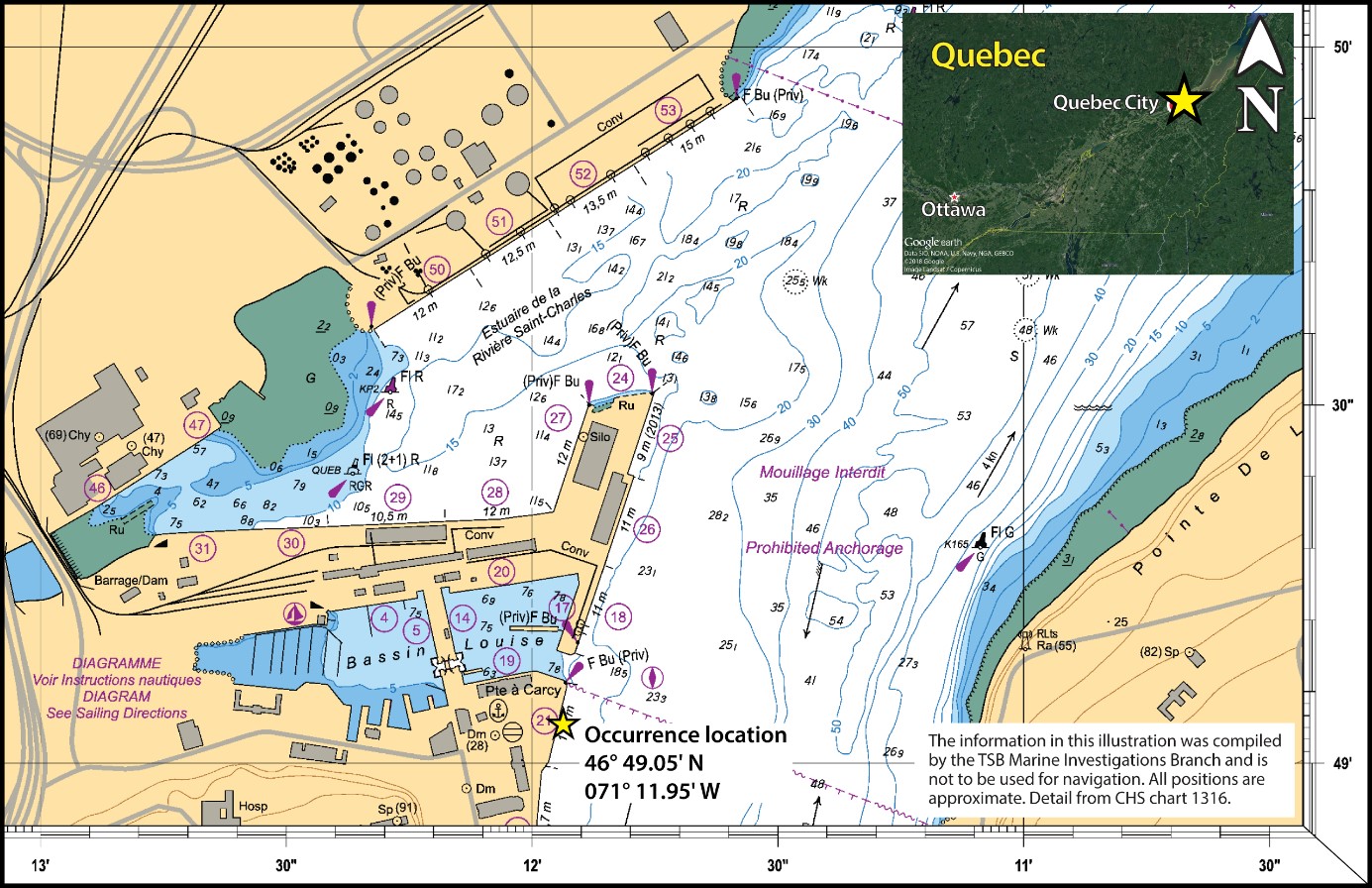

Source of main image: Canadian Hydrographic Service, Chart 1316: Port de Québec, with TSB annotations. Source of inset image: Google Earth, with TSB annotations

Appendix C – Technical drawing of Lifeboat No. 4 showing electromechanical limit switch

Source: D-I Davit International-Hische GmbH, with TSB annotations