Sinking and loss of life

Passenger vessel " TRUE NORTH II "

off Flowerpot Island, Georgian Bay, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 16 June 2000, while returning to Tobermory, Ontario, from Flowerpot Island, Georgian Bay, Ontario, in moderate sea and weather conditions, the small passenger vessel "TRUE NORTH II" was swamped by a series of waves which stove in the vessel's bridge front door, flooded the main deck and downflooded into the hull. The vessel sank rapidly in 15 metres of water approximately 200 metres off Flowerpot Island at about 1030 local time. Of the 20 people on board, 18 drifted ashore on two buoyant apparatus. Two grade-seven school children drowned.

1.0 Factual information

1.1 Particulars of the vessel

| Name | "TRUE NORTH II" |

|---|---|

| Official number | 369046 |

| Port of registry | Collingwood, Ontario |

| Flag | Canada |

| Type | Passenger Vessel |

| Gross tonnageFootnote 1 | 5.67 |

| Voyage Classification | Inland Waters Voyage, Class II |

| Length Overall | 10.6 mFootnote 2 |

| Draught | Forward: 0.9 m Aft: 1.0 m |

| Built | 1948, Russel Brothers Inc., Owen Sound, Ontario |

| Propulsion | One 120 - kW Cummins six-cylinder diesel engine |

| Crew | 1 |

| Passengers | 19 |

| Owner | True North Charter Services Ltd., Tobermory, Ontario |

1.1.1 Description of the vessel

The "TRUE NORTH II " is a small passenger vessel of closed construction, with a single chine hull form of all-welded steel, a transom stern, and a wooden open superstructure. The vessel is powered by a Cummins six-cylinder marine diesel engine rated at 120 kW, which drives a single fixed-pitch propeller, and gives a maximum speed of approximately 10 knots. The basic layout of the vessel is shown in the "Outline General Arrangement" (Figure 1).

The hull below the main deck is a common compartment extending from stem to stern, and contains the propeller stern tube gland and main engine, located near midships, and the rudder trunk gland and steering gear quadrant at the after end, near the transom.

A watertight steel trunk, arranged on the centreline forward of midships, extends above main deck level and encloses clear plastic panels fitted in the bottom shell plating. The clear panels allow viewing of underwater features such as shipwrecks at Fathom Five National Marine Park.

The wooden superstructure, which provides shelter from the weather for deck passengers, is open at the after end and has large passenger embarkation openings in the port and starboard sides forward of midships.

The steering position is at the forward end of the superstructure, on the port side. A door on the starboard side of the bridge front gives access to the open foredeck.

An inflatable liferaft and two buoyant apparatus are located on top of the superstructure. Two lifebuoys are stowed inside the viewing well coaming. The lifejackets are stowed in the upper port side of the main engine wooden casing.

1.2 History of the voyage

1.2.1 Outbound trip to flowerpot island

On 15 June 2000 a group of 13 school children, two supervisory teachers and two chaperons left the Bruce Township Central Public School, in Underwood, Ontario, for an overnight camping trip on Flowerpot Island. The "TRUE NORTH II" had been used by the school on four previous occasions to ferry grade-seven classes to Flowerpot Island. The island is within Fathom Five National Marine Park and is the only island with facilities for the public within the park. Access to the island is available through commercial tour vessels, which have permits issued by Parks Canada.

Upon arrival in Tobermory, the group loaded their gear and boarded the "TRUE NORTH II". At 1030 eastern daylight time, the vessel departed for a scenic tour of the harbour and the crossing to Flowerpot Island.Footnote 3 During the crossing, it was arranged that the "TRUE NORTH II" would return the next day to pick up the group at 1000 if the conditions were not too rough. Although the school group had a cellular telephone with them, it was normally turned off to save the batteries. No communications arrangements were made in the eventuality that the vessel was unable to return on time on the following day.

1.2.2 Decision to sail

On June 16, before he left home, the master listened to the weather forecast on 90.7 FM, the Parks Canada Weather and Activities Information radio broadcast, to decide whether he would sail. The master recalled that the forecast indicated winds south, 10 to 20 knots, increasing in the morning to 15 to 25 knots from the south-southwest, and that a small craft warning was in effect. The master continued listening to the weather forecast while driving to the harbour, as there was also a thunderstorm advisory.

The Environment Canada publication Wind, Weather & Waves: A guide to marine weather in the Great Lakes region mentions the area of the occurrence as being subject to a build-up of confused seas as a result of refraction. Due to the forecast and prevailing weather conditions, some local tour boat operators cancelled their trips for that morning.

At 0930 the master, accompanied by his dog, boarded the "TRUE NORTH II". There was no one else on board. The vessel departed Tobermory and proceeded directly to Beachy Cove, Flowerpot Island, to pick up the school group as agreed. As the vessel approached the south shore of Flowerpot Island, the master observed waves 1.0 m high, with some white caps and sea spray. The vessel arrived without incident at Beachy Cove at about 1000.

1.2.3 Returning from flowerpot island

After docking the vessel at the Parks Canada dock in Beachy Cove, and prior to loading the vessel with the camping equipment, concern was expressed to the master regarding the prevailing weather and sea conditions. The master gave reassurances and proceeded to load the vessel.

Two adult tourists, who had been brought to the island the day before by another boat operator, asked if they could return to Tobermory on the "TRUE NORTH II". The master agreed.

At 1012, when all of the 19 passengers were on board and their personal gear stowed, the master turned the vessel and left the cove at slow speed. The bridge front door leading to the foredeck was open. Upon departure, the master directed passengers to move forward to trim the vessel to ensure greater underkeel clearance at the after end while transiting the shallow entrance marked by two buoys near the breakwater.

At about 1022, when clear of the entrance, the master steered the vessel toward Tobermory (to the southwest) and generally bow into the wind and waves. At that point, the wind had increased to about 30 knots. Passengers on the open foredeck became wet from the heavy spray of the waves hitting the bow. One adult passenger fell to the deck due to water shipped over the bow. When the passengers on the foredeck entered the superstructure to seek shelter, the master left the wheel to close the door, secured it with its barrel bolt latch, and increased speed to approximately 7 knots.

1.2.4 Swamping, downflooding and sinking

Shortly after the passengers cleared the foredeck, a large wave was shipped over the bow and struck the bridge front door, reaching a height halfway up the front window. About 30 cm of water was trapped inside the bulwarks. Another wave was shipped and the accumulation of water retained on the foredeck reached the height of the bulwark top rail. The vessel became heavier by the bow. The master observed that the shipped water was draining slowly through the port and starboard scuppers. He instructed the passengers to move aft to help raise the bow as he maintained his course and speed into the waves.

At about 1025, as the vessel pitched and rolled into the waves, the master reduced the engine revolutions and put the rudder to starboard to turn the boat toward the island. Shortly after, a wave was shipped over the bow which stove in the bridge front door and window; waves were also shipped on the port side through the large side openings in the superstructure. Water flooded aft along the port side passageway. The shipped water was retained on deck inside the steel bulwarks at the after end of the vessel. Water retained on the foredeck and in the forward end of the superstructure flowed aft toward the stern and downflooded through various openings in the main deck. Passengers proceeding aft in the port side passageway had water suddenly reaching their knees, as the vessel heeled to port and more shipped water rapidly swamped the deck space. At about 1026 the vessel returned briefly to the upright and quickly sank by the stern in position 45°17.6′ N, 081°37.2′ W (Appendix A).

1.2.5 Abandonment

From the time the vessel started to ship water, the rapidity of the sinking was such that the master did not have time to give out lifejackets or prepare his passengers for abandoning the vessel. Some passengers were swept clear by the water. Others swam to the surface after abandoning the vessel by way of the bridge front doorway or the port, starboard and rear openings in the superstructure.

As the vessel heeled and sank, two orange rigid floats — called buoyant apparatus — located on the top of the superstructure floated free. The master reboarded the sinking vessel and stood on top of the superstructure, which was awash, but he was unable to reach the already-submerged inflatable liferaft, which remained secured to its cradle. Of the 20 persons on board, the master and 5 passengers clung to one buoyant apparatus, 12 passengers clung to the other. The buoyant apparatus, pushed by the 30-knot winds and 1.5 m waves, drifted separately onto Flowerpot Island. A head count of the passengers was not possible until after the two buoyant apparatus reached the shore. When it was found that two children were missing, a shoreline search was initiated.

The two schoolchildren who were missing were among the last to be seen on board the vessel. Their egress may have been hindered by various floating debris such as bench seats, the shuffle board, wooden panels and camping equipment trapped inside the superstructure as the vessel sank. In the week following the sinking, the team of professional divers engaged to clear the wreck confirmed that most of this debris was still trapped and floating in the superstructure.

1.2.6 Alerting

There was no distress call or any emergency radio communication transmitted by the "TRUE NORTH II" before it sank.

At 1045 the pleasure craft "PICKING DAISIES", en route to Tobermory, sighted the two apparatus with people in the water around them. The location was reported to the nearby Canadian Coast Guard (SAR) Station in Tobermory at 1049. Because of the shallow water near Flowerpot Island, the operator of the pleasure craft felt he could not approach the buoyant apparatus in the prevailing sea and wind conditions.

At about 1100, after reaching the shore, one child, accompanied by the master's dog, ran to the lighthouse to alert the Friends of Fathom Five volunteers of the sinking of the vessel. Realizing that the dog belonged to the owner of the "TRUE NORTH II", one volunteer, using a portable telephone, alerted the CCG Station that the "TRUE NORTH II" had sunk. By that time, the 12 persons with the second buoyant apparatus had reached the shore. The passengers, who had spent up to 50 minutes in 1.5 m waves and 10C water, were in various stages of hypothermia and shock. The park warden station near Beachy Cove was closed and, regardless, did not have any means of communication to alert the Park Warden.

1.2.7 Search and rescue operations

At 1050 the CCG Station in Tobermory informed the Rescue Co-ordination Centre (RCC), in Trenton, Ontario, that the “TRUE NORTH II” had sunk and the local SAR unit, “CCG 733” had been dispatched. At 1104 the “CCG 733” arrived at Beachy Cove to provide assistance to the survivors. Parks Canada staff also joined the rescuers to provide assistance. The “CCG SHARK”, a small Department of Fisheries and Oceans research vessel, arrived on-scene to participate in the search, and at 1125 the coxswain of the “CCG TOBERMORY” became the on-scene commander.

Floating debris and a patch of oil leaking from the "TRUE NORTH II" helped to locate the vessel on the lake bottom in about 15 metres of water in position 45°17.8′ N, 081°36.9′ W. At 1128, following a head count and a shoreline search, it was confirmed that two children were missing. The on-scene commander requested additional resources including an Ontario Provincial Police (OPP) helicopter to assist with the search for the two missing children.

At 1205, RCC Trenton established the first search pattern, which was completed at 1355. Further search patterns were undertaken throughout the day. At 2253, the search was suspended because of darkness. The area was searched by two Coast Guard cutters, an OPP helicopter, two Parks Canada vessels, and six private boats. During the afternoon, the survivors were evacuated from the island by two air ambulance helicopters and taken to Tobermory for medical examination.

On the morning of June 17, the OPP Underwater Search and Recovery Unit conducted an examination of the sunken "TRUE NORTH II" and located the bodies of the two missing children on the lake bottom near the vessel. The bodies were subsequently examined by the Coroner, who determined that the cause of death was drowning.

1.3 Injuries to persons

| Crew | Passengers | Others | Total | |

|---|---|---|---|---|

| Fatal | - | 2 | - | 2 |

| Missing | - | - | - | - |

| Serious | - | - | - | - |

| Minor/None | 1 | 17 | - | 18 |

| Total | 1 | 19 | - | 20 |

1.4 Vessel history

1.4.1 Construction history

The vessel was built in 1948 as a steel-hulled, flush-decked small fishing boat of closed construction, with a wooden deckhouse bolted to a 200 mm high steel watertight coaming, was fitted at the after end of the main deck in way of the underdeck steering gear quadrant.

The underdeck space was a common compartment throughout the length of the hull and was not fitted with any watertight transverse bulkheads. Such subdivision was not required by the Small Fishing Vessel Inspection Regulations.

A steel bulwark around the perimeter of the main deck, some 350 mm long, were installed in each of the port and starboard side bulwarks and fitted with outboard-swinging hinged steel flaps. The foremost pair of freeing ports was near midships, and the after pair was 2.4 m forward of the transom.

1.4.2 Vessel conversion history

The vessel was extensively modified and was renamed "CAPTAIN AHAB"; it entered service in 1972 as a passenger vessel. As part of the modification, the original deckhouse and all fishing-related gear were removed, the height of the steel bulwarks was raised to 585 mm, and an open wood-framed plywood superstructure was erected over the main deck to provide shelter for deck passengers.

Hull Construction Regulations (HCR) requirements applicable to passenger vessels call for subdivision of the hull by the incorporation of at least three transverse watertight bulkheads in order to retard the loss of stability and buoyancy in the event of flooding. This requirement is not applicable to passenger vessels with a gross tonnage of less than 75. Consequently, as a passenger vessel with a gross tonnage of 5.67, the hull of the "TRUE NORTH II" was not required to be subdivided, and was comprised of one common compartment.

The size of the opening in the main deck in way of the original deckhouse and engine casing was reduced, and the 200 mm high steel watertight coaming around its perimeter was removed. The engine casing was replaced with a semi-portable wood-framed plywood structure located inside the superstructure.

To ease access to the main engine, the lower plywood panels of the new casing were secured to the wooden framing with simple turn-button and slip bolt fastenings and were not attached to the main deck plating. The after end of the new casing was 405 mm forward of the original casing opening in the main deck, and this space was fitted with recessed flush-fitting wooden covers with no means of securing and no watertight gaskets.

The original steel hatch cover and its 75 mm high watertight coaming at the after end of the main deck were removed and replaced with a wooden hatch cover recessed into the deck, providing an unobstructed level surface in the passenger sitting area. The flush-fitting wooden cover was not fitted with a securing device or a watertight gasket.

An access hatch with a clear opening of 510 mm high steel coaming was installed in the main deck forward of the new superstructure. The hinged steel hatch cover was not fitted with a watertight gasket.

Two 32 mm high scupper opening was fitted at its centre.

Scuppers were installed in the port and starboard bulwark plating to provide drainage from the foredeck, with openings in the plating 140 mm diameter steel pipe, and closed at its forward end.

After these modifications, the First Inspection Report was completed and a Safety Inspection Certificate (DOT).

1.4.3 Structural modifications history

At various times during service as a passenger vessel, since 1972, structural and mechanical modifications and additions were made, the most significant of which were:

- the installation, in 1984, of a watertight steel trunk which encloses transparent panels in the bottom shell plating for underwater viewing;

- the fitting of hinged doors in the port and starboard side steel bulwarks to provide easy boarding and disembarking of passengers with a disability on to the main deck;

- the installation of a 430 mm access hatch in the main deck abaft the engine casing, which is fitted with a flush-fitting wooden cover with no securing device or watertight gasket;

- the hinged steel flaps of the main deck freeing ports__in the port and starboard side bulwarks near midships__were welded shut;

- the replacement, in the spring of 2000, of the original Cummins 63 kW.

Sketches and further details of items 1 and 2 were forwarded to DOT, prior to their incorporation in the vessel, and item 5 was completed before the routine annual safety inspection in the spring of 2000.

There is no record of when items 3 or 4 were installed, or if they were formally accepted. These modifications and the main deck non-watertight flush fitting hatches were present and accepted at each subsequent annual safety inspection where an SIC 16 was issued.

1.4.4 Vessel structural condition

The watertight integrity of the hull shell plating below main deck level was intact and leak free when examined while the vessel was afloat after her recovery. Localized pitting found on the internal surface of the shell plating was insignificant, and the extent and depth of any existing external pitting was such that it did not compromise the watertight integrity of the underwater hull at the time of the occurrence.

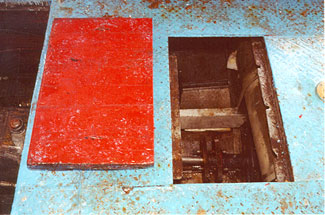

Neither the access hatches nor the main engine casing boundary in the main deck were fitted with watertight gaskets or securing devices. Any water shipped and retained on the main deck was thus allowed to freely enter the underdeck compartment (see photographs 2 and 3).

Main deck plating was extensively corroded around the boundary of an irregularly shaped opening that provided access to the main engine control, steering gear and electrical cables inside the wooden console at the steering position. This opening allowed any water shipped and retained on the main deck to freely enter the underdeck compartment.

The lower edges of the 75 mm above main deck level, and were not fitted with a means of closing. These openings allowed water shipped and retained on the main deck to freely enter the underdeck compartment as the vessel rolled or heeled to either side.

The lower edge of the portable plywood panel forming the after end of the engine casing structure did not extend down to the main deck level, leaving an opening 15 cm by 1.05 m wide across the bottom of the casing end. This opening was provided to enhance ventilation and air supply to the main engine. However, its location at deck level also allowed free entry into the underdeck compartment of any water shipped and retained on the main deck (see photographs 4 and 5).

The drainage scupper at the centre of the transom bulwark was found to be effectively sealed shut by a large decal, bearing the vessel's name, that was fixed to the outside of the transom.

This obstruction, in conjunction with the welding-shut of the two freeing ports near midships, reduced the vessel's ability to clear any water shipped on the main deck (see photographs 6 and 7).

The effective height of the port and starboard side bulwarks within the superstructure was 0.91 m, while that in way of the chain rails at the open after end of the main deck was 660 mm.

Visual, probing and mallet pounding examinations of the wooden superstructure in general, and the bridge front and its door and door frame in particular, showed areas of significant deterioration due to advanced and incipient rot (see photograph 8).

The wooden framing of the bridge front, console and door frame was discoloured and softened by decay, and the lower ends were partially disintegrated (see photograph 9).

The deteriorated condition of the inboard edge of the wooden frame in way of two of the three hinges of the bridge front door was such that the holding power of the 25 mm long screw fastenings was markedly reduced. The timber and wood packing in way of the hinge screw holes was decayed such that the screws were pulled clear with the door. The third and lowest door hinge remained attached to the door frame, and its screw fastenings were pulled clear from the door itself.

The 20 mm of the deck and consequently did not provide any support to the lower area of the door.

The 63 mm thick wooden door stop, forming a sill across the bottom of the door, had been unbolted and removed for repair the day before the occurrence. The sill had been replaced without its bolted connection, which reduced support to the lower area of the bridge front door (see photographs 10 and 11).

Reinorcement or repairs to the bridge front included the fitting of an additional layer of plywood over the original structure installed when the vessel was converted to passenger service. The inner layer of plywood was in a deteriorated condition due to dampness and rot, and several voids had developed between the layers where the inner layer had disintegrated.

The lower area of the outer layer was found to be soft when lightly probed and the unpainted edges of both layers of plywood exposed in way of the damaged hinges were discoloured and the wood fibres loose and brittle.

Over a period of time, the accumulation of standing water due to the loss of weathertightness of the lower bridge front structure would have led to the corrosion of the main deck plating inside the steering console and contributed to the decay and disintegration of the lower wooden framing.

The nature of the fractures and the colour of the exposed damaged surfaces of the wooden beams and plywood awning__in the area damaged from impact with the bottom__are consistent with the onset of decay and incipient rot in that area of the superstructure.

1.5 Vessel condition on recovery

Underwater video recordings showed the bow of the sunken vessel was pointing toward Flowerpot Island, that the hull was nearly level fore and aft, and resting on the port side bottom shell and bilge.

On June 24 the sunken vessel was raised to the surface; occurrence-related items noted during the subsequent inspections included the following:

- The steel hull up to main deck level was undamaged and structurally intact, with the bilges remaining dry after the recovered vessel was pumped clear of all flood water.

- All through-hull fittings of the main engine keel cooling and bilge pumping systems and the inboard glands of propeller and rudder shafts were undamaged and leak free.

- The after starboard quarter of the superstructure top was damaged and several wooden beams broken as a result of impact with the lake bottom.

- The wooden door on the starboard side of the bridge front was torn from its hinges, forced through its frame and retained inside the superstructure.

- The wood door stop and all securing bolts at the bottom of the bridge front door opening were missing, and the retaining stop at the outboard side of the door frame was bent aft through 90 degrees.

- The frame of the bridge front window forward of the steering position was stove in some 100 mm.

- The semi-portable lower side and after end panels of the plywood casing in way of the main engine were displaced and scattered inside the superstructure.

- The hinged upper plywood panels on the port and starboard sides of the engine casing lockers were open, and the lifejacket contents, pyrotechnics and firefighting gear exposed.

- All of the wooden flush-fitting hatch covers in the main deck were displaced.

- The inflatable liferaft on top of the superstructure was lashed secure in its cradle and one lifebuoy with safety light remained in its stowed position, while the other, with its heaving line, was on deck, having remained within the superstructure during the sinking.

- Unsecured passenger seating initially found by divers to have been displaced, was recovered or removed prior to the raising of the vessel, and the broken backrest of one passenger seat at the after port side of the main deck remained attached to the wooden framing of the superstructure.

- The passenger boarding doors in the port and starboard bulwarks at the forward end of the superstructure were secured in the shut position, and all bulwark safety chains around the after deck were in place.

- Passenger camping equipment was found stowed inside the steel trunk of the viewing well, and personal baggage, camping gear and the vessel's tool boxes, spares and other sundry gear were scattered on the main deck.

- The main engine control lever was found engaged in the forward drive position and the throttle was at the normal service speed setting.

- Starting and service batteries adjacent to the main engine were unsecured and had been displaced, probably as a result of impact with the lake bottom when the vessel sank.

- The outfit of electronic communications equipment was water damaged, the radar scanner dome fractured, and the vessel's funnel, found on the lake bottom near the sunken vessel, was recovered separately.

1.6 Vessel stability

When the vessel was built as a small fishing vessel in 1948, there was no regulatory requirement for the preparation and submission of stability data for approval purposes. The original builder is no longer in business, and there are no records of any hydrostatic particulars or stability data having been prepared.

On completion of her conversion for operation as a passenger vessel, and as part of the inspection and certification process, an estimate of the vessel's initial intact transverse stability was made in 1972.

At that time, and in the absence of more comprehensive hull design data, a rolling period test was carried out by the then GM)Footnote 4 of 0.677 m, and was accepted as a reasonable indication of satisfactory transverse stability characteristics.

After the "TRUE NORTH II" was raised to the surface, a rolling period test and a more comprehensive inclining experiment was carried out by the GM to be 0.704 m and 0.674 m, respectively.Footnote 5

Based on the lightship weight and the longitudinal and vertical centres of gravity derived from the inclining experiment, together with additional hydrostatics data generated by the TSB, a review was made of the vessel's trim and intact transverse stability characteristics for the various loaded conditions at the time of the occurrence.

Calculations show that on departure from Beachy Cove with all passengers, camping and personal equipment stowed on board, and with five persons located on the foredeck, the vessel was trimmed slightly by the bow. However, due to the after rake of the keel, the actual forward and after static draughts were 0.90 m and 1.0 m, respectively.

When approximately 0.3 m of water was shipped and retained on the foredeck, and passengers from the foredeck had just moved inside the superstructure, the forward trim increased slightly and the actual forward and after static draughts were 0.95 m and 1.0 m, respectively.

While passengers were making their way aft on the instruction of the master, and the water shipped and retained on the foredeck was level with the top of the bulwarks, the forward trim increased and the forward and after static draughts were 1.1 m and 0.93 m, respectively.

On departure, the GM was some 0.41 m, and the vessel still retained positive initial intact transverse stability.

The retention of a positive range of transverse stability was dependent on the vessel maintaining its intact watertight integrity; however, this integrity was compromised by the non-watertight condition of virtually all of the access hatches and other openings in the main deck.

The longitudinal and transverse stability of the vessel were markedly reduced by the weight and free-surface effects of the large volume of water shipped through the port side openings in the superstructure.

The clearing of shipped water from the main deck inside the open superstructure was retarded, as two of the four original freeing ports had been welded shut. The shipped water, which was retained on the after end of the main deck, caused the vessel to trim by the stern and also downflooded through non-watertight openings and accumulated in the underdeck compartment.

The additional weight of the water suddenly shipped when the bridge front door was stove in further reduced the transverse stability as it surged aft along the port side alleyway and also caused the vessel to trim rapidly by the stern. The vessel initially heeled severely to port, as transverse stability was virtually eliminated due to the increasing free-surface effects of water shipped and retained above the main deck and the accumulated downflooding water inside the hull.

The action of the relatively high waves on the vessel caused a transitory rolling motion to starboard, and as the wave actions continued, the vessel variously heeled or was rolled to port and starboard as she settled deeper in the water.

Downflooding into the underdeck compartment became continuous, and water accumulated until the vessel lost all reserve buoyancy and sank by the stern.

The extent and rapidity of the downflooding, which caused the sudden heeling to port and stern-first sinking of the "TRUE NORTH II", together with the obstructions caused by unsecured passenger seats, personal baggage, and camping equipment that became buoyant as the vessel settled, all contributed to the difficulties encountered by the passengers in abandoning the inside of the superstructure.

1.7 Downflooding and sinking sequence

The loss of reserve buoyancy was brought about by the accumulation of water inside the hull resulting from the rapid and progressive downflooding of shipped water through non-watertight hatch covers and other openings in the main deck of the vessel.

Rolling and heeling effects, imparted by wave motions while the vessel was trimmed by the stern and sinking, preclude a precise determination of the many trimmed attitudes the vessel could have taken. However, based on the reported sequence of events, the chronology of the occurrence__from the initial shipping of water over the bow to the subsequent sinking__can be determined, and is illustrated in Figure 2.

1.8 Vessel inspection and certification

1.8.1 Passenger vessel inspection

Pursuant to the Canada Shipping Act (CSA), the inspection of passenger vessels is carried out by Transport Canada, Marine Safety (TCMS), in accordance with the Hull Inspection Regulations, to ensure compliance with the appropriate regulatory requirements, including the HCR.

On satisfactory completion of an annual inspection by TCMS, a SIC 16 is issued, and the vessel’s current structural and other safety-related data are recorded in the Ship Inspection Reporting System (SIRS).

Each annual inspection is intended to be comprehensive, and includes examination of the hull, machinery, shafting, steering, pumping, electrical, life-saving, firefighting, navigation and communications outfits. Internal and external inspections also address the general structural condition of the vessel, including hatchways, ventilators, casings and other deck openings, together with their closing and securing appliances. Crew numbers, certification status, qualifications and operating limitations are also reviewed at this time.

"Standards for the Construction and Inspection of Small Passenger Vessels" (TP 11717) was published by the (then) Ship Safety Branch of the CCG in June 1994. The standards address a range of small passenger vessels including those (similar to the "TRUE NORTH II") with gross tonnages less than 15 and which carry more than 12 passengers. The standards include requirements addressing stability, subdivision, hull and deck watertight integrity, minimum freeing ports area and passenger deck railing heights. However, the standards are only applicable to new vessels and, because her conversion to passenger service took place in 1972, before TP 11717 came into effect, the "TRUE NORTH II" was not subject to this standard.

It is the responsibility of the operator to inform the inspector or bring to the attention of TCMS during the annual inspections are brought to the attention of the operator in order that remedial action can be taken.

In addition to regulatory requirements, two construction standards and a compliance program addressing the safety of passenger and other small vessels have been compiled, published and implemented by TC. These incorporate safety requirements, including hull subdivision for small vessels and charter vessels, which are more stringent than the regulations applicable to passenger vessels under 75 gross tons.

1.8.2 "TRUE NORTH II" inspection

Since entry into service as a passenger vessel in 1972, regulations made pursuant to the TCMS.

Following modifications to the vessel in 1978, the "TRUE NORTH II" was re-measured by LSE) Regulations, in lieu of her previous Class VII rating. Class V required a lifeboat with means of launching and one or more inflatable liferafts to accommodate 75 per cent of the passenger and crew complement.

The then owner requested that the life-saving equipment on board the vessel at that time be accepted because of the impracticability of carrying a lifeboat, due to the small size of the vessel. In November 1978 the Board of Steamship Inspection granted an exemption from the requirement to carry a Class I lifeboat (Board Meeting 3470), subject to the following conditions:

- buoyant apparatus capable of supporting 100 per cent of the complement to be carried;

- voyages to be limited to fine and clear weather only between May 1st and October 15th of each year on Inland Waters Class II Voyages on the waters of Georgian Bay bound by straight lines drawn from Tobermory Harbour to Lat. 45°15′24″ N, Long. 081°36′12″ W, thence to Gigs Point, Cove Island and Turning Island to Tobermory Harbour;

- the vessel to be manned by two crew members in accordance with the Safe Manning Regulations; and

- compliance with all other requirements of the LSE Regulations for a Class V ship.

The Board of Steamship Inspection's exemption reiterated the requirement in the existing Safe Manning Regulations for the "TRUE NORTH II" to have two crew members and this requirement was continued in what are now known as the Crewing Regulations.

From 1978 to 1985, conditions 2, 3 and 4 were not recorded on the SIC 16s issued by TC after each routine annual inspection and TCMS did not ensure compliance with these conditions prior to the issuance of the SIC 16s.

Following the sale of the vessel in 1981, the current owner of the “TRUE NORTH II” operated the vessel alone every year until the time of the sinking. SIC 16s issued from 1986 to 2000 included a voyage limitation condition but contained no mention of the vessel having to be manned by two crew members. During this period, condition number 3 was not met and TCMS neither recorded the discrepancy nor required the operator to meet this condition.

In 1997, a 20-person inflatable liferaft was added on board the vessel and the total number of passengers and crew indicated on the SIC 16 was lowered from 21 to 20 persons to reflect the liferaft's maximum carrying capacity.

The inspection certificate issued on 22 May 2000 was valid for Inland Waters Class II voyages until 21 May 2001.Footnote 6 The vessel was equipped with one inflatable liferaft capable of accommodating 20 persons, two 10-person capacity buoyant apparatus, 2 lifebuoys, 23 adults' lifejackets and 3 children's lifejackets. The vessel was certified for the carriage of 20 passengers and one crew member, for a total of 21 persons, which exceeded the rated capacity of the inflatable liferaft.

It was reported that, between 1996 and 2000, there were instances when the school had sent a group of 25 children and 4 adults, a number of passengers that exceeded the limit of 20 indicated on the vessel certificates.

The May 2000 certificate also contained the following notation regarding voyage limitation:

Tobermory to Flowerpot Island & Cove Island, in fine clear weather only at master's discretion. Between May 15th and September 30th.

This notation is at variance with the 1978 decision of the Board of Steamship Inspection. The notation also assigns a discretionary role to the master which was not a part of the Board's decision.

1.9 Parks Canada operators' permits

To operate within Fathom Five National Marine Park, commercial tour operators are required to submit an "Application for Commercial Operators Permits" and to enter into a "Commercial Vessel Operating Agreement" with Parks Canada. The application for the permit states that the applicant agrees to conform to the provisions of the "Commercial Vessel Operating Agreement" as well as to applicable federal and provincial laws. At the time of the occurrence, Parks Canada had signed the agreement but the master of the "TRUE NORTH II" had not. Neither the permit nor the Agreement contained a weather-limiting clause.

1.10 Master's qualifications and certification

In 1979 the master of the “TRUE NORTH II” worked a total of 100 hours as a crew member on the vessel when it was registered as the “CAPTAIN AHAB”. When he purchased the vessel in 1981, he applied for a Master of a Small Craft (CSC) Certificate. A local Transport Canada examiner conducted an oral examination and issued him his first CSC certificate. The Automated Certification and Examination System shows that, until 1997, the master of the “TRUE NORTH II” held a CSC certificate issued by TCMS.

In November 1983, the master of the “TRUE NORTH II” completed a first Marine Emergency Duties (MED) Level 1 course at Georgian College, Owen Sound, Ontario. The 30-hour course covered the syllabus for the MED 1 training.

In 1998, with the passing of the new Crewing Regulations, TCMS issued a Master, Limited (CL), certificate on the basis that the master of the “TRUE NORTH II” held a CSC certificate. This new certificate allowed him to work as master on his vessel when operating out of Tobermory in the marine park, not more than two miles off shore. The new CL certificate was issued for a five-year period and was valid until May 2003. Upon examination, TCMS also issued him a Restricted Engineer’s Certificate, Motor Ship, valid for Inland Waters Class II voyages.

In April 2000 the master completed a second MED course at the Georgian College MED Centre in Port Colborne, Ontario. A total of 64 hours of instruction was given covering all sections of the approved syllabus for the MED B1 (survival craft) and MED B2 (marine firefighting) courses.

Between 1980 and 2000 the master gained operational experience on his vessel in the marine park. At no time, however, did he attend a marine college to gain more formal education and training in the five main areas covered in the Master, Limited, syllabus.

1.11 Weather conditions

Marine Communications and Traffic Services (MCTS) Thunder Bay, Ontario, provides the continuous marine broadcast of Environment Canada's marine synopsis, forecasts and warnings for the Tobermory area on channels 21B and 83B. The regular forecasts are issued three times a day at 0300, 1030 and 1830. On June 16 the 0300 marine forecast for Lake Huron and Georgian Bay stated the following:

small craft wind warningFootnote 7 in effect [. . .] small craft thunderstorm advisoryFootnote 8 in effect [. . .] winds southerly 10 to 20 knots increasing to 15 to 25 this morning [. . .] waves 1 metre or less, building to 1 to 2 metres this morning.

The advisory also stated that:

winds are for mid lake [. . .] wave heights are for offshore and are forecast from trough to crest [. . .] near shore winds and waves may vary considerably due to shoreline effects.

Between 0926 and 1126 that morning, Environment Canada's remote weather station at Cove Island, which is about 4 nautical miles west of Flowerpot Island, recorded southerly winds of 15 knots gusting to 29 knots. At 1000 the master of the "TRUE NORTH II" estimated that the wind was from the south to southwest, gusting up to 25 knots. At 1110 the "CCG SHARK", which was in the area where the "TRUE NORTH II" sank, recorded southwesterly winds gusting at 30 to 40 knots and seas 1.3 m high with whitecaps and foam.

1.12 Navigation aids and instruments

Two small buoys maintained by Parks Canada are located near the end of the breakwater at Beachy Cove. The buoys mark the narrow and shallow channel leading to the tour boat dock inside of the breakwater.

The "TRUE NORTH II" was equipped with a magnetic compass and a small radar. Navigation was conducted by sight in daylight hours.

1.13 Communications

1.13.1 Radio communications

The "TRUE NORTH II" was equipped with two very high frequency (VHF) radiotelephones and had a Radio Inspection Certificate (Great Lakes) valid until 12 May 2001. Radio communications were heard between two other stations during the transit to Flowerpot Island but the master did not use the radio during the return voyage from Flowerpot Island. There was no emergency (portable) VHF radio on board and there is no standard requiring such equipment.

MCTS Thunder Bay provides radio communication services for Lake Huron and Georgian Bay. This includes monitoring channel 16 for vessel distress communications, providing weather forecasts and advisories, and facilitate ship-to-shore communications. Vessel movements may also be monitored by MCTS Thunder Bay. The “TRUE NORTH II” was not required to report to MCTS Thunder Bay nor was MCTS Thunder Bay aware of its movements.

1.13.2 Distress alerting equipment

There was no automatic or manual distress radiotelephone alerting system such as digital selective calling (DSC) or an emergency position-indicating radio beacon (EPIRB) on the vessel to alert the SAR authorities of a distress situation as well as the position of the vessel in case of emergency. At the time, no such equipment was required by regulations for this class of vessel.

1.14 Passenger safety

1.14.1 Life-saving equipment plan

A life-saving equipment plan that details the location and use of safety equipment for the benefit of the crew and passengers is a safety and regulatory requirement. The "TRUE NORTH II" did not have one. During the annual inspection and certification of the vessel, TCMS overlooked the requirement for such a plan and did not ensure one was displayed on board. Except for a small sign above the lifejacket compartment, there were no other signs indicating the location and use of life-saving equipment.

1.14.2 Crewing level and safety briefing

The Board of Steamship Inspection (Meeting 3470) required a second crew member for the vessel. However, since 1979, each ship inspection certificate stated that only one crew member was required. After the accident, in June 2000, TCMS determined "that it had incorrectly certified the vessel with respect to the number of crew required to be on board during operations."Footnote 9

During the trips to and from the island, there was no pre-departure safety briefing regarding the availability, location, and instructions for the use of life-saving equipment such as lifejackets, liferafts, and buoyant apparatus, and none of the 19 passengers were made aware of emergency procedures. A safety briefing, although important, is not required by regulations and the master did not include such a procedure in his departure routine.

1.14.3 Lifejackets

The inspection certificate issued for the vessel listed 23 adults' and 3 children's lifejackets. Found on board after the sinking were 22 adults' lifejackets, and 2 children's lifejackets. Also found in the lifejacket locker was a personal flotation device for a child.

Minimum safety requirements contained in the LSE Regulations require the carriage of a sufficient number of lifejackets for the ship's entire complement of passengers and crew. The regulations require passenger vessels (Classes IV through VII), where the vessel regularly carries a known number of children as passengers, to carry enough lifejackets suitable for every child.

There are two sizes of standard lifejacket approved for use:

- for a body mass more than 40 kg, and

- for a body mass 40 kg and under.

Since one of the three required children's lifejackets was a personal flotation device, not a certified lifejacket, the vessel was not equipped with the required number of children's lifejackets as shown on the vessel's certificate.

None of the lifejackets on board the vessel was fitted with a personal locator light. Furthermore, none of the lifejackets were retrofitted with a personal locator light as per TCMS record of Board Decision No. 6220 of 31 October 1996.

The passengers did not know where the lifejackets were stowed (see photograph 12).

The lifejackets were stored in a compartment above the main engine along the port side passageway. The upper half of the compartment has a door that is hinged along the bottom and is secured closed by a barrel bolt latch located at each end along the top of the door. To access the lifejackets, both barrel bolt latches must be opened to allow the door to swing out and down into the passageway. A small sign with the word "LIFEJACKETS" painted in red on a white background, in 19 mm high lettering, was fitted close to the deckhead, above and inboard of the door top panel. The outer face of the compartment door had several posters of interest attached to it. There was no poster on the vessel illustrating how to don a lifejacket.

Individual lifejackets were not readily accessible to passengers, in that each lifejacket was stowed in a tied plastic garbage bag. Removing the lifejackets from the tied plastic bags would have been time-consuming. The plastic bags were used to protect the lifejackets from water, ultraviolet rays and the fumes from the exhaust of the engine.

1.14.4 Buoyant apparatus

Since its conversion in 1972, the "TRUE NORTH II" was equipped with two buoyant apparatus. They were located on top of the superstructure and forward of the funnel. They were not lashed and floated free from the sinking vessel, as they were designed to do. Each buoyant apparatus was manufactured in 1971 and was approved for 10 persons. When the vessel sank, the master and passengers clung to the two buoyant apparatus. After being immersed in 10°C water for up to 50 minutes, survivors suffered varying degrees of hypothermia.

1.14.5 Inflatable liferaft

On 22 May 2000 the "TRUE NORTH II" was certified for service and received an inspection certificate that listed one inflatable liferaft capable of accommodating 20 persons and two buoyant apparatus capable of accommodating a total of 20 persons. The inspection certificate and the liferaft inspection certificate were valid until May 2001.

In 1997, following discussions with TCMS inspectors, the vessel was equipped with an inflatable liferaft. A 20-person Dunlop-Beaufort liferaft was installed in a cradle located on top and at the after end of the wooden superstructure. It was secured by a nylon lashing, which was attached to the cradle by a shackle at one end of the lashing and by a Senhouse slip at the other end. Such a securing arrangement requires human intervention for the launching. The master did not have ready access to the liferaft, as there was no means, such as a ladder, to climb atop the superstructure where it was stowed. Its installation on the vessel was accepted by TCMS inspectors (see photograph 13).

After being washed out of the vessel, the master swam on top of the superstructure but did not reach the inflatable liferaft in time to release it before it sank with the vessel. Since 1978, safety requirements provide for either deep chocks or a hydrostatic release unit to allow the liferaft to float free. Without the benefit of a liferaft, passengers were immersed in the cold water for up to 50 minutes as they clung to the buoyant apparatus; this increased their risk of hypothermia and drowning.

1.14.6 Lifebuoys

There were two lifebuoys on board, one fitted with a float-activated light, the other with a buoyant lifeline. Each lifebuoy was held in place by two U-shaped brackets attached to the inside of the viewing well coaming.

The lifebuoys were accessible to the master and the passengers, but they were stowed in the viewing well, which also contained carry-on baggage that partially covered the lifebuoys. Neither of the lifebuoys floated clear of the vessel when she sank; there was no regulatory requirement for them to do so.

2.0 Analysis

2.1 Decision to sail

On the morning of the occurrence, the master twice made conscious decisions to transit between Little Tub Harbour and Flowerpot Island. The first decision was to transit to Flowerpot Island in the face of the small craft warning and the thunderstorm advisory issued by Environment Canada. On arrival at Flowerpot Island, the master had an opportunity to remain alongside at Beachy Cove until the sea conditions improved. While he had just made the crossing in near gale-force winds and fielded concerns about the weather conditions, the master elected to proceed with the return voyage. The master's decisions to sail to and from Flowerpot Island were shaped by his perception of the risks associated with the transit.

2.1.1 Perception of risk

The master was aware that a small craft warning and a thunderstorm advisory were in effect but he believed that the crossings could be made.

The master's perception of risk was tempered by his previous exposure to similar and worse conditions in over twenty years of operating this vessel in this area. Upon departing Little Tub Harbour, the "TRUE NORTH II" was in the lee of the Bruce Peninsula; the waves there were smaller than on the more exposed, windward side of Flowerpot Island, where confused seas prevailed due to the shoreline effect. Also, while some operators decided not to sail to Flowerpot Island that day, the master knew that the shallow draught of the "TRUE NORTH II" allowed him to enter Beachy Cove where other, larger vessels could not proceed.

The vessel's inspection certificate did not clearly state the operational limitations on the vessel, as it allowed the master to proceed "in fine clear weather only at master's discretion." The first part of the limitation is open to interpretation but the second part, "at master's discretion," allowed the master to base his decision to sail upon his own judgement of the risk associated with the weather.

The master understood neither the serious shortcomings of the vessel's condition (with regard to watertight integrity) nor the effect that the southwest wind would have on his vessel; he overestimated the ability of his vessel to withstand the head-on encounter with the waves, and underestimated the result of shipping water.

2.1.2 Pressure to sail

While specific arrangements had been made to pick up the group at 1000 the following day, no contingency plans were discussed and no alternative plans or telephone communications were made on the morning of June 16 to cancel or postpone the trip due to poor weather. As a result, the master would have felt a personal commitment to proceed to Flowerpot Island to rendezvous with the school group.

2.2 Master certification and training

The master's certification met the minimum requirements of the Crewing Regulations to operate the "TRUE NORTH II" in the trade in which she was engaged.

From 1981 to 1997 the master held a CSC certificate, renewable annually at the beginning of the navigation season. In 1998 he was issued, without examination, a CL certificate on the basis of holding a CSC certificate. The new CL certificate simply reflected the criteria previously stated on the CSC certificate. The CL certificate is a certificate of competency which has to be renewed every five years. Even though every applicant for a CL certificate must pass an oral, practical and written examination, the TCMS examiner may renew the CL certificate without examination if he or she is satisfied that the holder has continued to operate in the same capacity for the last five years.

When examining a new applicant for a CL certificate, the TCMS examiner determines whether the person is competent to operate a specific vessel in a designated area where certain constraints, such as weather, can be expected. To assess a candidate, the TCMS examiner is guided by the general requirements for the CL certificate. The examination is based on a syllabus that encompasses various aspects of vessel operation such as navigation safety, engineering knowledge, general seamanship, ship management, and chart work and pilotage.

The examination and certification practices for the CSC or CL certificates are left to the discretion of the local TCMS examiner. The local examiner determines which part of the syllabus is appropriate to the operation, type of craft and equipment carried on board and conducts oral examinations which, in rare cases, may be supplemented by written papers. The knowledge required to understand local weather forecasts or to recognize shortcomings with a vessel’s watertight integrity is not part of the syllabus for this certificate. Since 1993, an instruction to TCMS examiners covered the preparation and evaluation of oral examinations, the latest version of which was issued on 30 June 2000. The instruction states that special care should be taken to document responses that are unsatisfactory or where the candidate is borderline.

The master was last given an oral exam in 1983. As there is no documentation as to how the examination was conducted, it is not possible to determine how the TCMS examiner assessed the master's competence in operating the "TRUE NORTH II".

In April 2000 the master took MED Level 2 training at Georgian College. The master continued to stow the lifejackets and the liferaft in the same manner as before and he did not institute a passenger safety briefing or conduct an emergency drill or exercise.

2.3 Crewing level

In December 1978, at the request of the previous owner, the vessel was re-measured by TC and a gross tonnage of 5.67 was assigned. The Board of Steamship Inspection then required, among other things, that the vessel carry two crew members for the safety of passengers. In 1979 the present owner was hired as a second crew member. Since 1981, when the vessel changed ownership, the new owner operated the vessel single-handedly.

The TCMS inspectors did not ensure that the operator had engaged a second crew member to meet the requirement for a crew of two, prior to the issue, each year, of the SIC 16. The certificates made no reference to this requirement. This meant that an additional crew member trained in emergency and survival procedures was not available to assist the master during the sinking. An additional crew member, if properly trained, might have been able to assist in the handing out of lifejackets to passengers or in the launching of the inflatable liferaft located on the top of the superstructure.

2.4 Meaning of "fine clear weather only at master's discretion"

Passenger vessel inspection certificates issued by TCMS contain limitations with regard to voyage and weather. The intent of the limitations is to reduce risks to passengers on small vessels.

The master had worked on this vessel in the area of the marine park since 1980. During this period he had experienced a range of weather and sea conditions. When he sailed the morning of June 16, he had listened to the weather broadcast and was aware of the weather, the small craft warning, and the thunderstorm advisory.

The Ship Inspection Certificate restricted the vessel to sail in "fine clear weather only at master's discretion." This notation is imprecise and does not define any physical wind and sea limitations useful for small vessel operators. The master considered that the operating restriction did not prevent him from proceeding to Flowerpot Island, nor from returning to Tobermory, in the prevailing weather and sea conditions.

The Board of Steamship Inspection exemption permitted the vessel to sail in "fine and clear weather only . . . ." The Ship Inspection certificates were different, in that the vessel was permitted to sail in "fine clear weather only at master's discretion." This element of discretion, which made the limitation less restrictive, was not contained in the original exemption.

Definitions of "in fine weather" vary from one official publication to another. For example, Transport Canada's Recommended Code of Nautical Procedures and Practices (TP 1018), states that "the officer of the watch should pay particular attention to the state of the weather and sea." This would suggest that "weather" is distinct from "seas". The Home-Trade, Inland and Minor Waters Voyages Regulations also refer to voyages "in fine weather," but without any definitions. The Interim Guidelines to the Interim Passenger Vessel Compliance Program also introduce voyage limitations and provide an expanded definition of voyages "in fair weather only" as "fine, clear settled weather, with a sea state such as to cause only moderate rolling and/or pitching."

The lack of a clear definition of "in fine weather," and industry-wide understanding of its derivations, leaves the interpretation of the limitation up to individual masters and would be dependent on the size and design of their vessels. Some may take it to mean atmospheric and sea conditions, while others may take it to mean atmospheric conditions only. The use of the qualifier "at master's discretion", which is often appended to the limitation, further calls into question the effectiveness of such a limitation.

2.5 Vessel condition after recovery

Inspection of the recovered vessel showed that the shell plating and underwater fittings of the "TRUE NORTH II" were intact and effective in preventing the entry of flood water into the hull. However, the lack of watertight integrity of the main deck--due to the non-watertight condition of three access hatches, the main engine casing and ventilators--made the vessel highly vulnerable to downflooding in the event of water being shipped on board. Since the non-watertight openings were distributed throughout the length of the main deck and water downflooded through all of them, transverse watertight subdivision would not have provided protection against progressive flooding.

In order to ensure adequate drainage of shipped water from exposed decks, the HCR require that vessels of all classes and tonnage be fitted with bulwark freeing ports as set out in the Load Line Rules. The actual freeing port area in the steel bulwarks on each side of the "TRUE NORTH II" was approximately 10 percent of the minimum requirement and, consequently, the rate at which shipped water could be cleared from the main deck was severely limited. That two of the four freeing ports with which the vessel was originally fitted were welded shut exacerbated the situation and led to the rapid accumulation of shipped water on deck and the subsequent downflooding of the underdeck compartment.

The total effective area of the foredeck scuppers was equivalent to one 75 mm internal diameter pipe, and any increase in their efficiency due to the venturi (suction) effect of their external cowlings was only effective when they were fully immersed and the vessel was making significant forward progress. The water which was shipped over the bow and retained up to the level of the bulwark top rail amounted to some 1.3 tonnes. While this was draining through the scuppers and also flowing aft through the gap at the bottom of the bridge front door, the vessel remained trimmed by the bow. While so trimmed, the vessel was vulnerable to shipping more water over the bow and the bridge front was also exposed to further wave impacts.

The wood-framed plywood superstructure was open on each side and at its after end, and was intended to provide some shelter from the sun, wind and inclement weather for passengers carried on the main deck. Because of its greater exposure to headwinds and bow spray, the bridge front was constructed with two layers of 12 mm thick plywood, while the remainder of the superstructure sides and the bridge front door were made from a single layer. While the bridge front structure was more robust than the remainder of the superstructure, the forward facing window and its frame was of less than fully weathertight construction and unsuitable to withstand the loads and impacts imposed by "solid" water. The single layer plywood construction and insubstantial securing devices and hinges of the bridge front door made it more vulnerable in the event of waves being shipped over the bow.

The deteriorated condition of the bridge front and its wooden framing in way of the door and window frames and the reduced support in the lower area of the door were such that, in the event, the bridge front door and window were unable to withstand the forces imposed on them.

The effective height__in way of the ship side guard chains across the transom and at the after end of the open superstructure__of 0.670 m was less than the 1.0 m minimum safety requirement. While this condition was not a factor in the vessel's sinking, it presented an unnecessary risk to passengers, especially on a vessel that routinely carries groups of children.

2.6 Vessel inspection

The operators of small passenger vessels may not always be conversant with all safety requirements and may rely on the annual inspection as a means of ensuring compliance with all of the various government regulatory requirements. From the time of her entry into service as a passenger vessel in 1972, until 2000, the “TRUE NORTH II” was inspected annually in accordance with the Hull Inspection Regulations to ensure compliance with HCR, LSE and other regulatory requirements. Throughout this 28-year period various modifications and additions to the structure, propelling machinery and safety equipment were carried out, which were inspected and accepted by the (then) CSI, and latterly by TCMS.

The details of past annual inspections recorded in SIRS, together with copies of the previous SIC 16, were routinely used as the basis upon which subsequent annual inspections were conducted. However, the continual reliance upon previously recorded data and approvals as a means of quickly assessing the current status of the vessel did not achieve the fundamental intent of the annual inspection, which was to provide an accurate safety audit of the vessel’s current condition. This practice led to the repeated acceptance of unsafe features, including non-watertight unsecured hatches and openings in the main deck, inadequate main deck freeing port and drainage arrangements, and insufficient crewing.

The conduct of annual inspections of similar vessels in the above manner became the established normal practice of TCMS, and developed into what may be termed “a routine annual inspection syndrome” in which the previously accepted structural features and information were not questioned or subjected to renewed scrutiny. Consequently, safety audits related to each of the annual inspections of the “TRUE NORTH II” were based on initially inaccurate assessments of the watertight integrity and the water-freeing capability of the main deck. As a result, the safety audit defences, which should have been integral to each inspection, were lost.

The scheduling of inspections of small passenger vessels in the Tobermory area is dictated to a large extent by the seasonal nature of the tourist industry, and most operators seek to have their vessels inspected just prior to the start of each summer season. In practice, to cope with the resultant congestion, several annual inspections were routinely conducted on the same day by whichever TCMS inspector was currently available. The inspectors so employed over the years had knowledge and experience in the various available fields of expertise, including nautical, marine engineering, hull, and small vessels.

Since the annual inspections were carried out on the "TRUE NORTH II" by individual inspectors with specialized knowledge in certain fields and limited cross-training in others, this led to a reluctance to question previously accepted features that were outside an inspector's particular field of expertise. Such inspection procedures contributed to the continued acceptance of shortcomings in the vessel's condition.

The perennial continuation of such oversights was the result (in part) of inadequate quality assurance procedures in relation to the administration and monitoring of the annual ship inspection program by TCMS District and Regional offices.

2.7 Passenger safety briefings

The operator of the "TRUE NORTH II" did not provide a safety briefing to his passengers. Although such a briefing is not a regulatory requirement, TCMS has issued Ship Safety Bulletin (SSB) No. 4/95 recommending the practice. The passengers were not aware of the location of the lifejackets, or the use of the buoyant apparatus and the liferaft on the vessel. The teachers who had been on the vessel on several previous occasions were unaware of the location of the lifejackets. Once in the water, some of the passengers tried to open the buoyant apparatus believing the lifejackets were inside.

In order to prepare for emergency situations, passengers must be well informed of any safety precautions and emergency actions, including the location of emergency equipment available on board. Safety briefings provide critical information to passengers and prepare them for successful evacuation in the event of an emergency. Previous TSB recommendations (M94-04 and M96-05) identified this deficiency, but it continues to be identified in spite of action taken by the authorities.

2.8 Life-saving equipment

It is important that crew members have access to life-saving and emergency equipment to distribute to the passengers to increase their survivability when a vessel is being abandoned.

2.8.1 Carriage and stowage of lifejackets

The inspection certificates showed that, from 1980 to 2000, the number of adults' lifejackets carried on board the "TRUE NORTH II" varied between 21 and 25; the number of children's lifejackets varied between 2 and 6.

None of the surviving passengers knew where the lifejackets were stowed. Information submitted to TCMS in the spring of 1984 indicates the lifejackets were to be stowed in the benches located on the afterdeck. However, the lifejackets found on the “TRUE NORTH II” were stowed in a compartment located along the port side passageway directly above the main engine. An opening in the deckhead for the smoke stack and air intake exposed the lifejackets to rain, smoke and ultraviolet light. Rather than modify the compartment, the owner had wrapped the lifejackets in opaque plastic bags to protect them. This practice, routinely accepted by TCMS inspectors who inspected the “TRUE NORTH II”, made the lifejackets less conspicuous.

This situation was not improved by the lifejacket signage. The placement of the sign and the size of the lettering were not sufficient to effectively advise passengers of the location of the lifejackets. In addition, the posting of tourist-related information on the compartment door below the lifejacket sign competed for the viewer's attention. The inadequacy of the signage could have been overcome through a pre-departure safety briefing alerting the passengers to the location of the lifejackets.

A lifejacket is designed to provide buoyancy and to keep an unconscious wearer's head face-up above the surface when in the water. For the lifejacket to perform as designed, the size of the lifejacket must be appropriate to the body size of the wearer. If the lifejacket is too big or too small, or is worn incorrectly, the wearer can be at risk of drowning.

Current regulations require passenger vessels, similar to the "TRUE NORTH II", to carry enough lifejackets for the number of adults authorized to be carried under the inspection certificate issued for the vessel. However, only 10 percent of that number must be lifejackets "suitable for children." Only when the vessel "regularly" carries a known number of children as passengers, is the vessel required to have one lifejacket for each child. In the event of an emergency, it is critical to the safety of all passengers that they each have a suitable lifejacket.

2.8.2 Buoyant apparatus and lifebuoys

The LSE Regulations permit a vessel to carry buoyant apparatus instead of a liferaft, provided certain safety requirements are met. In this occurrence, since the vessel sank without the liferaft being deployed, the buoyant apparatus were critical to the master and passengers reaching shore successfully. However, as the buoyant apparatus offered only a small surface area, the master and the passengers were immersed in 10°C water. Consequently, they found it difficult to cling to the apparatus and were at severe risk of hypothermia. It should be noted that the vessel sank some 200 m directly upwind of Flowerpot Island, and the waves pushed the apparatus directly towards the island.

Because the lifebuoys were stowed inside the viewing well, they were contained within the superstructure and did not float clear of the vessel as she sank.

2.8.3 Inflatable liferaft securing and deployment

In 1996 the owner added an inflatable liferaft to the life-saving equipment on board the vessel. The lashing that secured the liferaft in the cradle was fitted with a Senhouse slip that required manual operation in order to deploy the liferaft. The liferaft was not readily accessible, as there was no provision for easy access to the top of the superstructure. Although launching the inflatable liferaft is considered a two-person operation, the vessel was operated single-handedly, and prior to departure the master did not brief any of the passengers to assist him in this task in the event of an emergency. After swimming to the top of the superstructure, the master could not reach the already immersed liferaft in time to manually release the Senhouse slip. As a result, the liferaft sank with the vessel.

The liferaft was required to be fitted with either a hydrostatic release unit or to be stowed in deep chocks (without lashings). The absence of either of these devices had not been identified by TCMS inspectors in 1996 when the liferaft was installed, and none was fitted thereafter. As a result, the lashing that secured the liferaft to its cradle was not fitted with a hydrostatic release device or other means to allow the liferaft to float free when the vessel sank.

2.9 Emergency communications

Due to rapidly moving events, the situation became difficult to manage, and after the bridge front door was stove in, the master could not transmit a Mayday or distress signal nor make any request for assistance on the VHF radio. Except for that radio, the vessel had no other means of alerting the CCG station or the parks warden that the vessel was in distress. Like most small passenger vessels, the “TRUE NORTH II” was not required to carry an automatic distress alerting system such as an EPIRB to alert SAR authorities in the event of a distress situation. At present, passenger vessels under 20 m in length are not required to carry an EPIRB.

As there was no sailing plan with a pre-determined time of departure and arrival, no one in Tobermory was aware that the vessel had been lost. Consequently, SAR authorities were not aware of the distress situation until a passing pleasure craft observed the two buoyant apparatus and notified the local Coast Guard radio station.

3.0 Findings

3.1 Findings as to causes and contributing factors

- The master sailed to Flowerpot Island in near gale-force winds, while a small craft wind warning and thunderstorm advisory were in effect.

- On the return voyage, successive waves stove in the vessel's bridge front door and window, and shipped water rapidly flooded the main deck through the front and port side openings of the superstructure.

- Ineffective scuppers and insufficient freeing port area caused the shipped water to be retained on deck and quickly downflood the underdeck compartment through non-watertight hatches and deck openings. As a result, the vessel lost reserve buoyancy and sank rapidly by the stern.

- Modifications to the vessel had compromised its watertight integrity.

- The absence of a pre-departure safety briefing, the inconspicuous lifejacket sign, and the lack of an emergency equipment plan resulted in the passengers being unaware of the location and use of life-saving appliances on board the vessel.

- At the time of the sinking, the master was in sole charge of the vessel, with no other crew member available to guide or render assistance to the passengers during and after the abandonment.

- The inflatable liferaft stowed on the top of the superstructure was not readily accessible and required human intervention for its deployment. The liferaft sank with the vessel because it was neither placed in deep chocks without lashings nor fitted with a hydrostatic release unit.

3.2 Findings as to risk

- Since 1972, unsafe structural features were improperly assessed during the vessel's annual inspections by TCMS, and remedial action was not taken to address these risks.

- In the event of underwater damage, the risk of loss of stability and sinking is greatly increased by the absence of transverse watertight bulkheads.

- The continuous acceptance of structural shortcomings was the result of, in part, inadequate quality assurance procedures in relation to the administration and monitoring of the annual ship inspection program by TCMS.

- The voyage limitation on the Ship Inspection Certificate restricted the vessel to sail "in fine clear weather only at the master's discretion." Such wording is imprecise and does not adequately define wind and sea parameters.

- The vessel was required to be crewed by two persons, but this requirement was not implemented and subsequent Ship Inspection Certificates made no reference to the requirement for an additional crew member.

- Due to the rapidity of the sinking, the master did not transmit a distress call on the SAR station, which increased the on-scene response time.

- Unsecured debris floating inside the vessel's superstructure may have posed an increased risk to passengers trying to escape the sinking vessel.

3.3 Other findings

- The master and 17 passengers, who were not wearing lifejackets, escaped the sinking vessel and swam to two buoyant apparatus which drifted to Flowerpot Island in the onshore wind.

- TCMS examination and certification procedures did not require examiners to file a report on their assessment of a candidate for oral examination. It is not possible to determine how the examiner assessed the master's competence in operating the "TRUE NORTH II".

- The syllabus for Master, Limited, does not cover ship construction or meteorology, two subject areas that might have helped the master to recognize the vessel's vulnerability.

4.0 Safety action

4.1 Safety Action taken

4.1.1 Advisory on liferaft release mechanism

In October 2000 and January 2001 the MSA 00-09) to Transport Canada indicating serious shortcomings with the inspection of life-saving equipment and the lack of a float-free arrangement for liferafts on many small passenger vessels operating in Canadian waters.

In response, TCMS has indicated that an amendment to the LSE Regulations has been prepared and will require vessels under 25 m in length to have liferafts, if fitted, that will “float free” if the vessel sinks. In the interim, TCMS has drafted a Ship Safety Bulletin to address the stowage and float-free arrangements for liferafts.

4.1.2 Review of passenger vessel inspection and certification

As a result of this occurrence, TCMS made recommendations in four key areas:

Regulatory Review and Audit

- to review a sample of small passenger vessels' files in different regional offices to detect non-conformities;

- to institute a formal process of monitoring inspectors' reports on inspections;

- to avoid the use of "fair or fine weather" and to define a set of parameters such as sea states;

- to review regional directives; and

- to initiate a National Marine Safety Circular from headquarters to the regional offices, and to clients.

Operations and Inspections

- to update notices to surveyors;