Engine room fire

Roll-on/roll-off ferry Holiday Island

Wood Islands, Prince Edward Island

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Executive summary

The ferry Holiday Island operated on a 75-minute route that crosses the Northumberland Strait between Caribou, Nova Scotia, and Wood Islands, Prince Edward Island (PEI). On 22 July 2022, the vessel departed for Wood Islands on the 2nd voyage of the day. As the vessel approached Wood Islands, the fire alarm sounded in response to an engine room fire. The engines were shut down immediately and the fuel supply valves were closed shortly afterward. The master purposely beached the vessel on a sandbar to the west of the channel, outside the entrance to the Wood Islands terminal, and both anchors were dropped. The crew attempted to fight the fire locally but were unable to do so successfully. In part because of the smoke and heat, the air intake vents on the housetop deck were not closed. A remote release of the carbon dioxide (CO2) fixed fire suppression system was unsuccessful. When the crew noticed this, the system was activated with a manual release and was partially successful. The vessel’s fire team began boundary cooling.

Preparations for evacuating passengers and non-essential crew members began while the fire teams were responding to the fire. Crew members assisted passengers down both marine evacuation system slides and into the life rafts. The crews of nearby vessels evacuated passengers and non-essential crew from the life rafts and took them to the reception point at the Wood Islands dock. Approximately 1.5 hours after the fire alarm first sounded, all passengers and crew members who were not part of the fire response had left the vessel.

As shore-based firefighters boarded the vessel to assist, boundary cooling was expanded to the housetop deck and to the funnel deck and the firefighters began to monitor temperatures. At this time, a significant amount of smoke was coming out of the air intake and exhaust vents for the engine room.

Close to high tide, at 1850, the stern of the Holiday Island floated free. The Holiday Island had been listing approximately 2° to 3° to port since the early afternoon. By 2017, the list had increased to approximately 5° and by 2044, it was listing approximately 10° to port.

At 2148, out of concern for their safety, persons still on board (approximately 40) were evacuated. The fire continued to burn, and smoke from the engine room vents and stack continued to be visible until mid-afternoon on 23 July. On the morning of 24 July, the Holiday Island was towed to the Wood Islands terminal and the on-board vehicles were unloaded later that day. The vessel was later declared a constructive total loss.

In the course of the occurrence, different numbers of passengers and crew were recorded. The master initially reported a passenger count of 182 and a crew count of 23 (a total of 205). In total, 236 passengers were counted at the reception point.

The investigation found that a series of temporary repairs to a leaking fuel rail had been made over a period of approximately 1 month before the occurrence using non-standard materials and methods, while the vessel remained in service. When the final temporary repair to the leaking fuel rail failed, fuel sprayed onto the hot engine components and ignited.

The investigation also found the following:

- At the beginning of the firefighting response, water from a fire hose likely spread the burning engine fuel around the engine room and contributed to the spread of the fire.

- An unlubricated component of the fuel valve assembly prevented the fuel valve from closing fully, allowing the contents of the day tank to drain through the damaged fuel rail and fuel the fire in the engine room.

- The crew believed they had activated the CO2 fire suppression system, because the resistance felt when the CO2 release mechanism cable was pulled provided a false indication of success.

- The guidance posted was not explicit. Consequently, the CO2 release was delayed, allowing the fire to grow. When the CO2 was released, the engine room space was not completely sealed. Air continued to enter the space through open vents, likely displacing the released CO2 and also adding oxygen to the fire. Consequently, the fire continued to burn.

- The flexible connection between the cooling system and the forward main engine was not protected against heat and fire. When the flexible connection was damaged by the fire, seawater from the vessel’s cooling system entered and began flooding the closed engine room.

The investigation identified safety deficiencies related to policies and procedures for emergency responses and communication on the part of the crew, the vessel operator, and first responders. Specifically, the investigation also identified safety deficiencies related to accounting for passengers in case of an emergency. Lastly, the investigation identified safety deficiencies related to oversight by the authorized representative (AR) or their delegate, leading the Board to issue a recommendation.

Knowledge of the scope of the role and responsibilities of authorized representatives

Under the Canada Shipping Act, 2001, an AR, typically the vessel’s owner, is the person who is responsible for acting with respect to all matters relating to the vessel that are not otherwise assigned to another person. The AR must keep up with changes in safety knowledge, standards, and regulations. Where matters are assigned by regulation to another role, such as the master, the AR remains responsible for oversight of those matters. In addition to ensuring regulatory compliance, the AR or the AR’s delegate plays a proactive role in ensuring safety. Given the scope of the AR’s responsibilities, the relationship between the master and AR is critical and collaboration is essential for the continued safe operation of a vessel. For example, this collaboration requires ongoing assessment by both the master and the AR to ensure that procedures are understood, followed, and accurately represent all operations and that they also comply with regulations.

As this investigation and many others demonstrate, the role of the AR is not always clearly understood. Transport Canada expects the AR to understand the scope of the role – that is, to take proactive measures to learn which regulations apply to their vessel and how to follow them. As such, the Board recommends that

the Department of Transport provide comprehensive guidance for authorized representatives, outlining the full scope of their responsibilities. This guidance should support authorized representatives in understanding and complying with applicable regulations, thereby reducing the risk of vessels and crews operating without the minimum safety defences afforded by regulatory compliance.

TSB Recommendation M25-01

1.0 Factual information

1.1 Particulars of the vessel

| Name | Holiday Island |

|---|---|

| International Maritime Organization number | 7041431 |

| Official number | 344866 |

| Port of registry | Charlottetown, PEI |

| Flag | Canada |

| Type | Roll-on/roll-off passenger ferry |

| Gross tonnage | 3037 |

| Registered length | 98.60 m |

| Breadth | 20.48 m |

| Depth | 5.79 m |

Built | 1971, Port Weller Dry Docks Ltd., St. Catharines, Ontario, Canada |

Propulsion | 2 diesel engines, each with a Voith Schneider propulsion system, for a total of 5408 kW |

| Maximum complement | 399 (381 passengers) |

| Owner and authorized representative | Minister of Transport, Canada |

| Operator | Northumberland Ferries Limited |

| Recognized organization and issuing authority for International Safety Management certification | Lloyd’s Register |

1.2 Description of the vessel

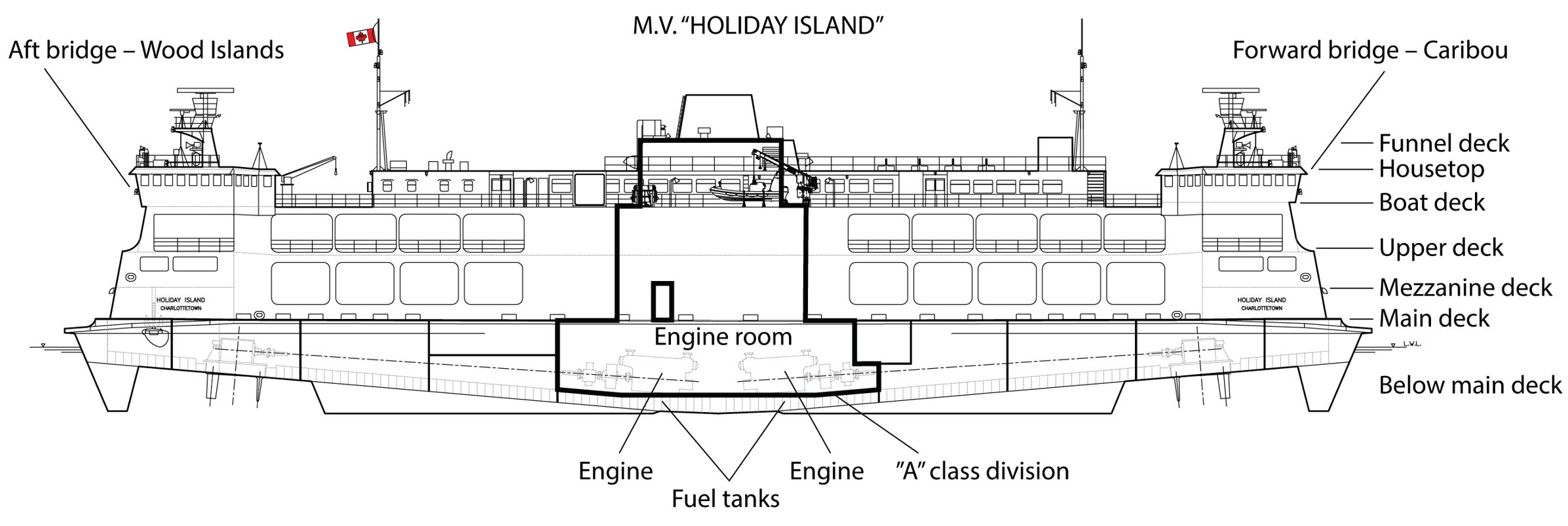

The Holiday Island was a double-ended roll-on/roll-off ferry of steel construction (Figure 1) built in 1971. The vessel had 6 decks: the main deck (also called the truck deck), the mezzanine deck, the upper deck (also called the car deck), the boat deck, the housetop deck, and the funnel deck (Appendix A).

The 2 enclosed bridges,The convention on the Holiday Island was to refer to the bridge facing Caribou, Nova Scotia, as the forward bridge and the bridge facing Wood Islands, Prince Edward Island, as the aft bridge, irrespective of the direction of travel. Similarly, port and starboard are always the same sides. This report follows the same convention. crew accommodations, and offices were located on the boat deck. Each bridge was equipped with

- navigational equipment, including radars, an echo sounder, and an electronic chart system;

- a simplified voyage data recorder;

- propulsion controls at the centre helm position and at both bridge wings;

- control panels for the ballast system and for the fire detection and alarm system;

- remote controls for the fire doors on the main and upper decks and remote controls for the watertight doors below the main deck; and

- remote carbon dioxide (CO2) release stations.

Communication equipment included 2 very high frequency (VHF) radios, 1 VHF–DSC (digital selective calling) radio, 2 sound-powered phones, and a public address (PA) system. Three portable VHF radios were also available on board.

The pre-embarkation areas for the 2 muster stations were on the boat deck outside each bridge. The life rafts, marine evacuation systems (MESs),A marine evacuation system is ”life saving equipment that consists of one or more inflatable life rafts, a slide or chute as a means of embarkation into the inflatable life rafts and, in the case of a system with more than one life raft, an inflatable rescue platform.” (Source: Transport Canada, C.R.C., c. 1436, Life Saving Equipment Regulations (as amended 19 June 2024), subsection 2(1)) and emergency generator were also located on the boat deck. The emergency generator fuel tank, the fan room, and the furnace rooms were located on the housetop deck. The fuel tank for the accommodations furnace was located on the funnel deck immediately above the fan and furnace rooms.

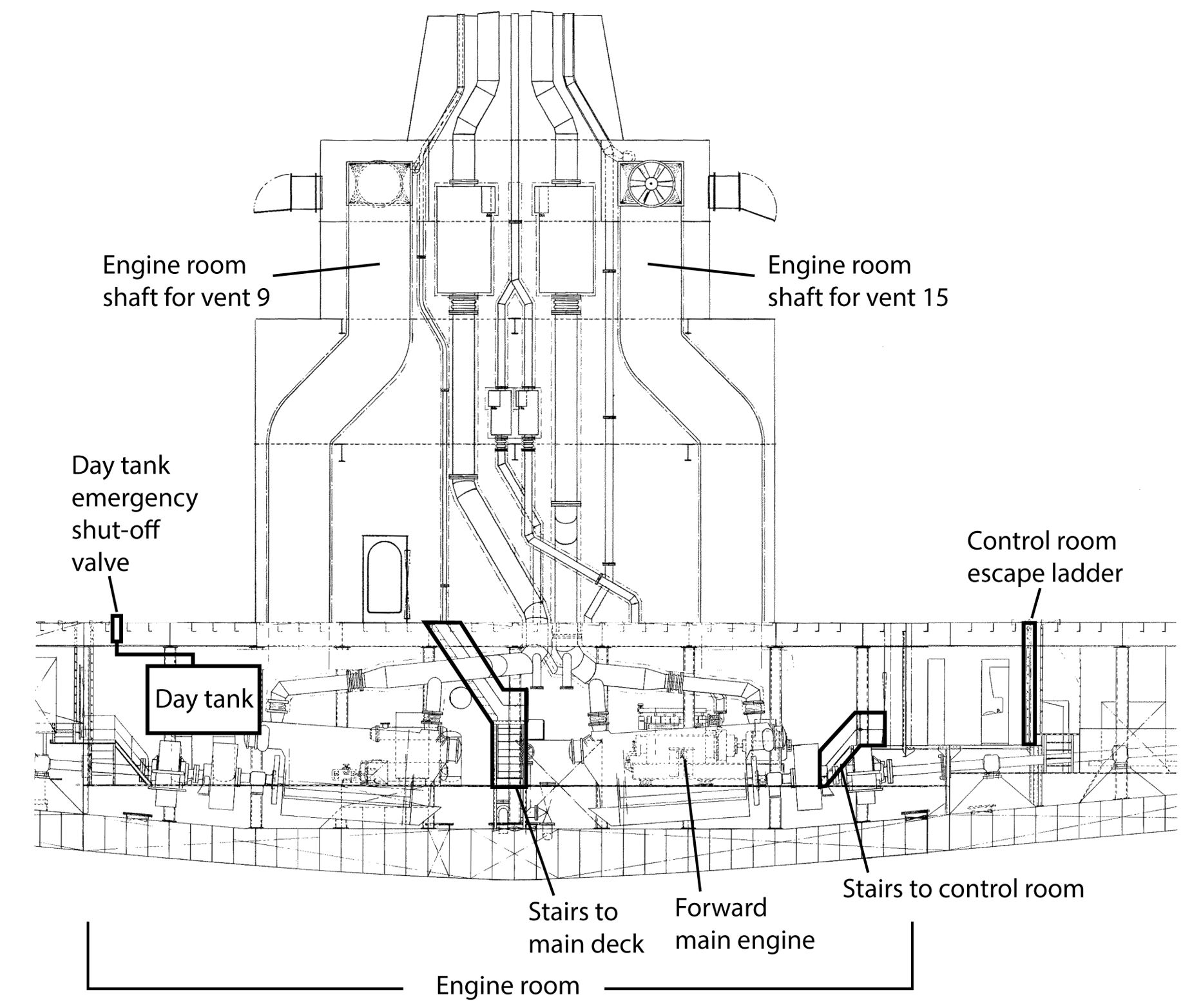

The main engine room, the engine control room (ECR), the auxiliary engine room, a workshop, and a crew dayroom, as well as fuel tanks, water tanks, and other compartments were located below the main deck. The 4 double-bottomed fuel tanks and the 2 sea chests for the engine cooling systems were located below the main engine room.

1.3 History of the occurrence

On 22 July 2022All times are in Atlantic Daylight Time (Coordinated Universal Time minus 3 hours). at 0839, the Holiday Island departed Wood Islands, Prince Edward Island (PEI), on the 1st voyage of the day, with 22 crew membersA 23rd crew member (electrician) had finished his rotation on the previous day. on board. The vessel operated on a 75-minute route that crosses the Northumberland Strait between Caribou, Nova Scotia, and Wood Islands, running 3 to 8 times per day, depending on the season.

At 0945, the Holiday Island arrived at Caribou and the passengers disembarked. Once disembarkation was complete, the passengers waiting to make the trip to Wood Islands began to board. Two motor homes, 1 5th wheel trailer, 2 tent trailers, 5 tractor-trailers, 1 cube truck, and 78 passenger vehicles were loaded. At 1004, the Holiday Island departed for Wood Islands. At 1005, the Caribou toll booth operator reported a passenger count of 182 to the bridge team on the vessel.

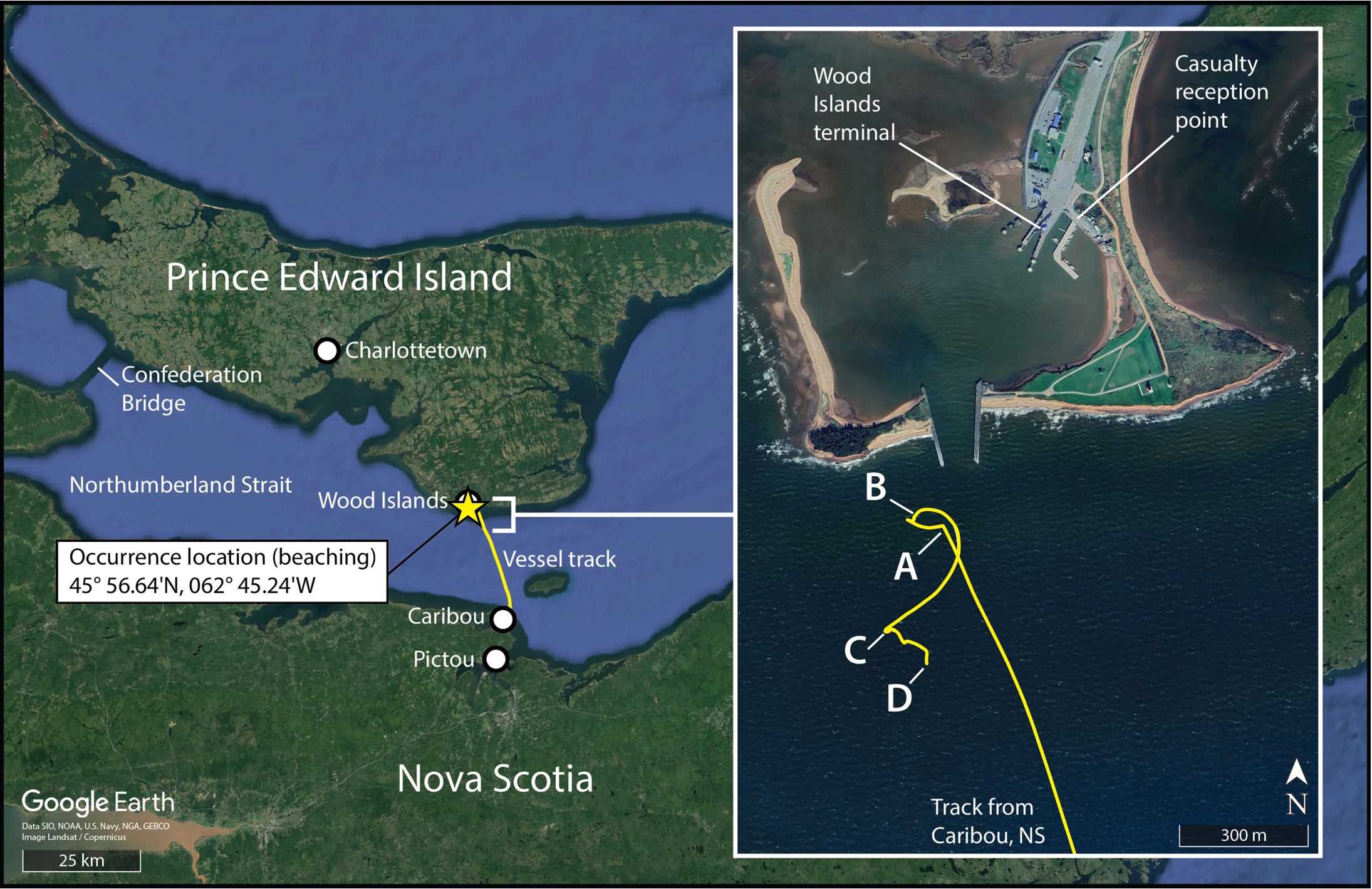

At 1106, as the vessel approached Wood Islands (Figure 2), the fire alarm sounded on the bridge and the fire detection panel indicated that there was a fire in the main engine room. At this time, the bridge team consisted of the master, the second officer, and the quartermaster. At 1107, the fire alarm sounded throughout the vessel.

The master used an intercom system to speak with the second engineer, who was in the ECR and who confirmed that there was a fire, informed the master that the engines had to be shut down, and then began to shut them down. The master then used the PA system to instruct all crew to prepare for an engine room fire. Deckhand 4 began to close vents and dampers. At the same time, the assistant engineer and the fourth engineer attempted to enter the main engine room from the main deck stairwell (Figure 3) but determined that the main engine room was too hot to enter. The assistant engineer went to don his firefighting suit.

Shortly afterward, the chief engineer went down to the main engine room. He also attempted to enter the engine room using the same door on the main deck but saw flames at the bottom of the stairs and closed the door. He then entered the ECR using the emergency escape hatch.

At approximately 1108, the chief officer met the bosun on the truck deck and they began to prepare the fire hoses for firefighting and boundary cooling. While they were preparing the hoses, the master contacted the chief officer on a portable radio and requested that he prepare to drop both anchors. The quartermaster, deckhand 3, deckhand 4, the chief officer, and the bosun went to the forward mezzanine deck to prepare to drop anchor.

At 1109, the master phoned the terminal manager at Wood Islands to report the engine room fire. The terminal manager then called emergency services (911) to report the fire and request assistance.The Wood Islands terminal manager and assistant manager updated the emergency services operator at 1116 and at 1125. At 1130, the terminal manager also contacted PEI Emergency Measures Organization and the Canadian Red Cross. From 1109 onward, the assistant engineer, deckhand 1, and the fourth engineer used a fire hose to spray water on the forward main engine from their position at the main deck entrance to the engine room.

At 1110, the master used the PA system to instruct all passengers and crew to muster at the muster stations. This announcement was interrupted on the bridge by another fire alarm. The passenger services crew members began to direct passengers outside so they could distribute lifejackets. Some adult passengers were issued child-sized lifejackets and some children were issued adult-sized lifejackets; no infant-sized lifejackets were available.

At 1112, the master beached the vessel on a sandbar to the west of the channel, outside the entrance to the Wood Islands terminal.

At approximately 1115, both anchors were dropped and the 2 deckhands left the anchor team. Deckhand 3 was instructed to don a firefighting suit and join the bridge fire team. On his way to join the bridge fire team, he stopped to help distribute lifejackets to passengers who requested assistance. Deckhand 4 helped the engine room fire team don their gear and returned to closing vents and dampers.

At 1116, the chief engineer and second engineer left the ECR through the escape hatch and closed it behind them.

At approximately 1117, from the main deck, the second engineer used the remote controls to close the fuel shut-off valves to the main engine. When the chief engineer joined the fire team on the main deck, the fourth engineer went to close vents and dampers with deckhand 4.

At 1118, the master instructed the quartermaster to close all engine room vents on the main deckThe engine room vents were located on the funnel deck and the housetop deck. in preparation for using the CO2 fixed fire suppression system. The master immediately radioed the chief officer and the engine room fire team to inform them that the engine room vents were closed.

At 1121, a radio operator at the Sydney Marine Communications and Traffic Services (MCTS) transmitted a Mayday relay distress message for the Holiday Island. At the same time, the JRCC (Joint Rescue Coordination Center) Halifax tasked the Canadian Coast Guard Auxiliary (CCGA) vessel Mellissa Jayne, a local fishing vessel, to assist with the evacuation.

At 1124, the second officer left the bridge to join the chief officer. Because the amount of smoke billowing out of the funnel area had intensified, they decided to deploy the port MES in preparation for an evacuation.

At 1126, the fire team at the engine room door radioed the master to say that they were unable to fight the fire, that the entrances to the engine room were closed, and that everyone was out of the engine room. The fire team began boundary cooling under the supervision of the second engineer. At this point, they observed that paint had started to melt on the main deck above the engine room.

At 1127, from the bridge, the master activated the remote release for the CO2 cylinders. Around the same time, the fourth engineer returned to inform the fire team on the main deck that he had been unable to close the exhaust vents on the funnel deck because of the smoke and heat. The assistant engineer, who was still in his firefighting suit, donned his breathing apparatus, crawled under the smoke to the vents, and closed them.

Deckhand 4 went to close air intake vents 9 and 15Vents 9 and 15 were the main engine air intake vents. They remained open throughout the occurrence. on the housetop deck, which had to be closed from inside the fan room. The damper handle for vent 9 was in the closed position. At vent 15, the fan room was too hot and smoky to enter, so deckhand 4 closed the door by kicking it closed from the outside.

At 1142, the chief engineer observed that the amount of smoke coming out of the funnel area was increasing and temperatures were high. He went to the CO2 control room to check whether the CO2 had been released. When he confirmed that the pilot cylinders had not been discharged, he activated the main engine room CO2 cylinders manually using the pilot cylinders and went to the bridge to report to the master.

1.3.1 Passenger evacuation

Preparations for evacuating passengers and non-essential crew members began while the fire teams were responding to the fire.

At 1117, using the PA system, the master directed “all passengers and crew not involved in firefighting, [to] please muster to the muster stations.” The chief officer, the bosun, deckhand 2, and deckhand 3 joined the passenger evacuation teams.

Ashore, an operator from the 911 dispatch centre in Charlottetown, PEI, notified the JRCC that a ferry was on fire at Wood Islands and that it was being evacuated. At 1118, the JRCC asked an MCTS operator in Sydney, Nova Scotia, to transmit a Mayday relay. The JRCC also began to task air resources from the Canadian Armed Forces.

At 1119, the chief officer radioed to the bridge team that he was at the port MES,assisting with the passengers (Figure 4). Crew members who were familiar with the operation of the MESs gave instructions to the lined-up passengers who were within earshot.The megaphone was not working because the batteries were run down. At the same time, the JRCC tasked the Pictou, Nova Scotia, and Charlottetown inshore rescue boatsInshore rescue boats are fast rescue craft staffed by students and Naval Reserve personnel to support search and rescue operations in the busy summer season. to assist with the evacuation.

Between 1120 and approximately 1200, the terminal manager and the assistant manager prepared the Wood Islands terminal to receive the Holiday Island passengers and the shore-based first responders. The terminal manager assumed the role of on-site response commander of the shore response control centre, as described in the Northumberland Ferries Limited (NFL) procedures.Northumberland Ferries Limited, Confederation / Holiday Island emergency response manual (March 2022), Section 2.3: Shore Response Control Centres.

By 1130, the port MES slide was deployed by the chief officer. One crew member went down first to assist passengers in the life raft. By 1135, the bosun, second officer, and chief officer were assisting passengers down the slide and into the life raft.

At 1131, the alarm system began to sound on the bridge and throughout the vessel again and the bridge team was unable to silence it except by keeping the PA system active.

At 1133, as described in the NFL procedures for an evacuation, the master transmitted a Mayday call over VHF radio to report on the status of the Holiday Island and to announce that the crew were preparing to evacuate passengers from the vessel.

At 1136, the Mellissa Jayne arrived on scene and its crew began to evacuate passengers from the life raft. Many other nearby vessels arrived to help. Passengers boarded the vessels and were taken to the reception point at the Wood Islands dock. Shortly afterward, the second officer went to help with the starboard MES evacuation.

At 1138, the master provided Sydney MCTS with a passenger count of 182 and a crew count of 23; at 1140, this count (205 persons) was reported to the JRCC by MCTS.

At approximately 1147, the second officer deployed the slide at the starboard MES. Deckhand 3 entered the starboard life raft to assist passengers.As the passengers came down the slide, crew members at the top and bottom of the slide used signals to control the evacuation. From the life raft, the passengers boarded the responding vessels and were taken to the reception point at the Wood Islands dock. In total, 236 passengers were counted at the reception point.

At 1151, the master received reports that the bridge communications were being broadcast over the PA system because of the action taken to silence the fire alarm. Shortly afterward, a cloth was taped around the PA system handset so that conversations on the bridge were muffled.

By 1223, all passengers had left the vessel and the crew had searched the decks to confirm that no passengers remained on the vessel. By approximately 1228, crew members who were not part of the fire response had left the vessel.

1.3.2 Post-evacuation fire response

At 1231, the master was informed that shore-based firefighters from local fire departments had begun to arrive, bringing additional gear, such as air cylinders. A rope ladder was secured to the port main deck for the firefighters to use to board the vessel. At 1237, the master reviewed the vessel’s fire control plan with the firefighters. The vessel’s fire team began to take direction from the firefighters.

At 1242, the master advised the JRCC that he had accepted the firefighters’ assistance. At some points, more than 30 firefighters from various fire departments were on the vessel. The deputy chief from the Belfast, PEI, fire department remained on the Wood Islands dock and tracked the firefighters as they came and went from the vessel.

With the additional firefighters, boundary cooling was expanded to the housetop deck and to the funnel deck, where the fuel tank for the accommodations furnace was located. At this time, the assistant engineer and a firefighter observed a significant amount of smoke coming out of the air intake fan for the engine room (vent 15). They attempted to enter the space, but it was too smoky to see and too hot. The firefighters monitored temperatures using thermal cameras on board and with a drone (Figure 5). At the point when firefighters began boundary cooling on the funnel deck, the funnel temperature was approximately 113 °C and the temperature of the furnace fuel tank was approximately 90 °C.

At 1255, an NFL employee called the master to advise that a tugThe tug Svitzer Bedford arrived early on the morning of 23 July 2022. had been arranged from Port Hawkesbury, Nova Scotia, so that the Holiday Island could be towed to the dock and fire trucks could be used.

At 1318, the terminal manager, in his role as on-site commander, informed the JRCC that 13 crew members and 6 firefighters remained on board.

At 1339, a Transport Canada (TC) marine safety inspector arrived on board and joined the firefighters in directing the fire response. Monitoring and boundary cooling continued.

At approximately 1340, the CCG vessel Cape Spry arrived on scene.

At 1614, 13 crew members and 23 firefighters were reported on board. Firefighters were rotating on and off the vessel, and monitoring and boundary cooling continued. The fire was still burning and the vessel was listing slightly to port.

At 1734, the TC marine safety inspector suggested the crew consider releasing the auxiliary engine room CO2 cylinders. The crew and the firefighters traced the lines to determine how to release the auxiliary engine room cylinders into the main engine room and activated the pilot cylinders. After the pilot cylinders were activated, freezing was observed on the lines to the main engine room. Monitoring and boundary cooling continued.

Near 1830, NFL staff delivered some food and water to those on board and indicated that they planned to find a relief crew for the crew on board so that the fire response could continue until the vessel could be towed to the dock.

Close to high tide at 1850, the stern of the Holiday Island floated free. Between 1922 and 1945, the Holiday Island was towed approximately 270 m to a position further from the channel by the CCG lifeboat Cape Spry so that the passenger ferry Confederation could pass on its scheduled service. The Holiday Island remained in approximately 9 m of water; at the time, the vessel had a mean draft of 4.9 m.

At 1948, the vessel was listing approximately 2° to 3° to port, as it had been since the early afternoon.

At 2017, the TC marine safety inspector was replaced by another TC marine safety inspector. At this point, the Holiday Island was listing at approximately 5° to port.

At approximately 2030, a partial crew change on the Holiday Island was made.

By 2044, the vessel was listing approximately 10° to port. Crew began to sound the tanks and other spaces to determine if there was water ingress, and the firefighters and crew started planning how to pump water off the vessel. Using the thermal camera, firefighters observed that the temperature of a sounding pipe cap for 1 of the double-bottomed fuel tanks was 67 °C.

At 2107, the JRCC contacted the TC marine safety inspector who reported that the temperature of the fuel tanks was close to the flashpoint of the fuel (63 °C), and there was a risk of explosion. At 2116, when the JRCC could not reach the crew on the vessel, the JRCC advised the NFL vice-president of marine operations of the perceived risk. At 2120, the JRCC advised the first responders to prevent additional vessels and firefighters from approaching the Holiday Island.

At approximately 2125, the approximately 40 persons still on board were instructed to evacuate the vessel. At 2148, the evacuation was complete and confirmed. Smoke from the engine room vents and stack continued to be visible until mid-afternoon on 23 July.

On the morning of 24 July, the Holiday Island was towed to the Wood Islands terminal and the on-board vehicles were unloaded later that day.

The vessel was later declared a constructive total loss.

1.4 Environmental conditions

On 22 July 2022, the skies were partly cloudy. Winds were from the south-southeast at 5 to 10 knots and shifted to coming from the southwest later in the day. The wave heights were below 0.5 m throughout the day. The water temperature was approximately 20 °C.Sea Temperature Info, “Water temperature in Northumberland Strait (PEI) in July,” at https://seatemperature.info/july/northumberland-strait-water-temperature.html (last accessed on 15 July 2024). In Charlottetown, air temperatures reached 29 °C, and the humidex value was 38 °C at its highest point. On the day of the occurrence, the crew had logged that some areas of the vessel were too dangerous to work in because of the heat and humidity.

The first low tide of the day was at 1203 (0.8 m) and the next high tide was at 1850 (1.7 m).Fisheries and Oceans Canada, ”Wood Islands – 01680,” at https://tides.gc.ca/en/stations/01680/2022-07-22 (last accessed on 15 July 2024).

1.5 Personnel certification and experience

The master held a Master Mariner certificate of competency. He had completed International Convention on Standards of Training, Certification and Watchkeeping for Seafarers (STCW) Advanced Firefighting (AFF) training, most recently in January 2022. The master started his seagoing career as a fish harvester in the 1980s. In 1992, he began working as watchkeeper or chief officer on other types of commercial vessels. He began working for NFL in 2013 and had been master since 2016.

The chief officer held a Chief Mate, Near Coastal certificate of competency. He had completed STCW AFF training in April 2022. The chief officer had been working for NFL since 2012 and had been chief officer or second officer since 2014.

The second officer held a Master Mariner certificate of competency. He had completed STCW AFF training in June 2021. The second officer had been working with NFL as second officer or chief officer since 2019.

The chief engineer held a Second-Class Engineer, Motor Ship certificate of competency. He had completed STCW AFF training in 2017. The chief engineer had been working for NFL and Bay Ferries (an NFL subsidiary) since 2005 and had approximately 7 years of experience as chief engineer.

The second engineer held a Third-Class Engineer, Motor Ship certificate of competency. He had completed Marine Emergency Duties (MED) training modules C and D in 1991. The second engineer had been working as a watchkeeping engineer since 1971. He started to work on the Holiday Island in 1972 when it was owned by CN Marine. He had been working for NFL since 2001.

The fourth engineer held a Fourth-Class Engineer, Motor Ship certificate of competency. He had completed STCW AFF training, most recently in 2021. The fourth engineer had been working for NFL since 2013 and had been a watchkeeping engineer since 2015.

The assistant engineer held a Watchkeeping Engineer, Motor-driven Fishing Vessel certificate of competency issued in August 1985 and an Engine Room Rating certificate issued in April 2018. He had completed MED Basic Safety training in January 1985. The assistant engineer had been working for NFL since 2016.

The passenger services supervisor had first taken passenger safety management training in 2011. Her most recent certificate expired on 11 June 2022. She had completed MED Basic Safety training in 2008. The passenger services supervisor had been working for NFL since 2008.

1.6 Vessel certification

The Holiday Island held an inspection certificate for Near Coastal, Class 2 voyages, limited to ferry service voyages in the Northumberland Strait between the ports of Caribou and Wood Islands. The certificate was valid until 10 May 2023. The Holiday Island had been issued 3 safe manning documents by TC. The safe manning level depended on the number of passengers on board (Table 2).

Number of passengers | Number of crew |

|---|---|

0 | 11 |

1–184 | 16 |

185–381 | 18 |

The Holiday Island was classed with Lloyd’s Register and inspected by Lloyd’s Register acting as the recognized organization (RO)ROs are classification societies. Classification societies also certify international SMSs. under the Delegated Statutory Inspection Program (DSIP). The vessel operated under a safety management system (SMS). The SMS was certified and audited by Lloyd’s Register under the International Safety Management (ISM) Code.When the Holiday Island and NFL were first enrolled in the DSIP, an SMS was a pre-requisite for passenger vessels to participate. At the time of the occurrence, an SMS was not required by regulation. SMSs are now mandatory for all such vessels (Transport Canada, SOR/2024-133, Marine Safety Management System Regulations).

1.7 Authorized representative

The Canada Shipping Act, 2001 (CSA 2001), which came into force in 2007, is the legislation that governs marine transportation in Canada. One of the objectives of CSA 2001 is the promotion of safety in marine transportation. The role of a vessel’s authorized representative (AR) is described in section 14 of the CSA 2001 and in regulations made under the act. The CSA 2001 was a significant revision of the Canada Shipping Act (R.S.C. 1985), the previous legislation governing marine transportation. As part of this legislative update, the role of the AR expanded significantly, with added responsibilities such as developing procedures for safe operation and ensuring that vessels comply with regulations. Before 2007, the AR was primarily an administrative contact.

An AR is the personUnder Canadian law, a corporation is a separate legal person for the purposes of liability; thus, authorized representatives can be corporations. who is responsible for acting with respect to all matters relating to the vessel that are not otherwise assigned to another person. Even where matters are assigned to another person, the AR remains responsible for oversight of those matters. For Canadian vessels, the role of the AR is tied to ownership.For foreign vessels operating in Canada, the authorized representative is the vessel’s master. The AR must be the owner of the vessel (or 1 among joint owners) or the bare-boat charterer. Since June 2023, the owner of a vessel may delegate a qualified person to act as the AR for that vessel. A qualified person must be a Canadian citizen or permanent resident, or a corporation incorporated under Canadian or provincial laws.Government of Canada, Canada Shipping Act, 2001 (S.C. 2001, c. 26, as amended 23 June 2023), section 14.

1.7.1 Scope of responsibilities

The scope of AR responsibility covers many areas (see Appendix C for a detailed list). For example, ARs are required to provide vessel masters with written procedures. The procedures must cover familiarization with shipboard equipment, operational instructions, and assigned duties. ARs are also required to ensure that the vessel and its machinery and equipment meet regulatory requirementsIbid., subsection 106(1). and are seaworthy.Ibid., section 85. The AR also shares responsibility with the master for ensuring that the vessel and the people on board are protected from hazards.Ibid., section 109. In TC communications such as technical publications (TPs) and ship safety bulletins (SSBs), which relate to individual regulations or topics of interest to the marine community, TC explains the responsibilities of the AR, master, or other person responsible.

ARs and similar roles (safety designate, authorized person, qualified personThe roles of qualified persons are generally defined in terms of their qualifications, that is, their knowledge and experience. For example, in the Canada Occupational Safety and Health regulations, a qualified person “means, in respect of a specified duty, a person who, because of his knowledge, training and experience, is qualified to perform that duty safely and properly.” See Employment and Social Development Canada, SOR/86-304, Canada Occupational Health and Safety Regulations (as amended 15 December 2023), section 1.2: Interpretation.) are constructs that are used in other domains, both in Canada and internationally.For examples, see A. Jury and M. Pinsi, BSI/UK/1933/ST/0221/EN/AS, Person responsible for regulatory compliance (PRRC) – MDR/IVDR Article 15: An overview of the requirements and practical considerations (BSI National Standards Body), at https://www.bsigroup.com/globalassets/meddev/localfiles/fr-fr/whitepapers/wp---person-responsible.pdf (last accessed on 8 May 2025) and Netherlands Enterprise Agency, RVO, Product Safety and the Role of the Authorized Representative, at https://business.gov.nl/regulation/product-safety-and-role-of-authorised-representative/ (last accessed on 8 May 2025). There are differences in the details of these roles and between the marine industry and other domains. To assist ARs or their equivalents in understanding the scope of their responsibilities, some government departments and safety associations have developed training programs, manuals, information bulletins, and online resources.Canada Revenue Agency, “Responsibilities of authorized representatives,” at https://www.canada.ca/en/revenue-agency/services/e-services/represent-a-client/responsibilities-authorized-representatives.html (last accessed on 8 May 2025).,Transport Canada Civil Aviation, “Authorized Person Program and Bulletins,” at https://tc.canada.ca/en/aviation/training-pilots-aviation-personnel/authorized-person-program-bulletins (last accessed on 8 May 2025).For example, in Newfoundland and Labrador, WorkplaceNL (the province’s workplace injury insurance provider) requires that a workplace with fewer than 6 employees have a workplace health-and-safety designate.Government of Newfoundland and Labrador, Occupational Health and Safety Act (as amended in 2022), section 42.1: Workplace designate. The safety designate’s responsibilities are similar to that of a vessel’s AR in that they are responsible for the health, safety, and welfare of the people employed in their workplace. The Newfoundland and Labrador Fish Harvesting Safety AssociationNewfoundland and Labrador Fish Harvesting Safety Association, “The Fishing Vessel Safety Designate Program,” at https://www.nlfhsa.com/fvsd (last accessed on 8 May 2025). has developed a WorkplaceNL-approved, free, 6-hour online course that safety designates must participate in.

TC Marine Safety and Security (TCMSS) has voluntary programs that provide training and information for some vessel owners, although these programs do not name ARs explicitly:

- Small Vessel Compliance ProgramTransport Canada, “Small Vessel Compliance Program,” at https://tc.canada.ca/en/programs/small-vessel-compliance-program (last accessed on 8 May 2025). (for vessels under 15 gross tonnage [GT], including tugs and fishing vessels) training to help owners understand the scope of their responsibilities;

- Best Practices in Rental Boat Safety,Transport Canada, “Best Practices in Rental Boat Safety,” at https://rentalboatsafety.ca (last accessed on 8 May 2025). an online course for owners of rental boat operations; and

- TPs, SSBs, and other communications related to specific regulations and safety issues.

The investigation did not find any publicly available guidance or training from TC that describes the scope of AR responsibilities for other sizes and types of vessels.

Recent TSB investigationsTSB marine transportation safety investigations M22P0259, M20P0230, M20P0229, M18P0014, M16C0036, and M10F0003. have demonstrated that the scope of the responsibility that TC assigns to ARs is not well understood in the Canadian marine industry. Even for larger vessels, the role may be perceived as an administrative contact.For example, see S. Chapelski, “Canadian Maritime Law: Increased Penalties and Responsibilities for Authorized Representatives of Vessels,” Norton Rose Fulbright (25 October 2023), at https://www.nortonrosefulbright.com/en/knowledge/publications/0dcf3bc6/canadian-maritime-law-increased-penalties-and-responsibilities (last accessed on 8 May 2025). The TC website mentions AR responsibilities in a few places, primarily by quoting legislation and regulations.For example, refer to TC’s “Form 14—Appointment of Authorized Representative (form 84-0035),” which is required only if “the vessel is owned by more than 1 owner or by a foreign corporation,” under “Appointing a representative” at https://tc.canada.ca/en/marine-transportation/vessel-licensing-registration/apply-manage-vessel-registration/information-you-may-need-apply#toc-5 (last accessed on 8 May 2025). The authorized representative is also often mentioned in TC’s ship safety bulletins.

1.7.2 Owner and authorized representative of the Holiday Island

The Government of Canada’s Minister of Transport was identified as the registered owner and AR of the Holiday Island. At the time of the occurrence, TC owned 3 other ferries that operated on interprovincial ferry routes. The Minister of Transport is also identified as the AR for those vessels. The management of TC-owned ferries falls under the TC Programs Group.

Reporting to the Assistant Deputy Minister of Programs, TC Programs Group staff are responsible for programs related to all modes of transportation as well as environmental management, innovation, and waterways.Transport Canada, “Programs Group,” at https://tc.canada.ca/en/corporate-services/transparency/briefing-documents-transport-canada/20191120/20191120/programs-group (last accessed on 8 May 2025). Staff involved in the ferry program include the Regional Director, Programs, Atlantic Region; the operations manager and staff; and the capital projects manager and staff. For the day-to-day operations of the Holiday Island, the Regional Director, Programs, Atlantic Region acted on behalf of the registered owner.

Larger projects that require a budget beyond regular operating expenses are considered capital projects. TC Programs Group was responsible for identifying and funding capital projects and for working with NFL to implement these projects. For example, the 2022 installation of the MESs was a capital project.

The TC Programs Group staff who oversaw the TC ferry program were familiar with the government processes for capital projects, such as the acquisition of the MESs, and for routine funding, such as contribution agreements. Only 2 of the staff involved in the ferry program had marine experience and both reported to the capital projects manager. They focused on capital projects such as evaluating potential replacement vessels, though they would occasionally support the operations manager, if requested. Because ferry program staff considered that the day-to-day operation of the vessel, including maintenance procedures and other AR responsibilities, had been sub-delegated to NFL, they provided limited oversight or guidance on vessel operations.

TC Programs Group operates separately from TC Safety and Security. TC Safety and Security is responsible for the development of regulations and national standards and the implementation of monitoring, testing, inspections, and subsidy programs in the aviation, marine, rail, and road sectors.

Reporting to the Assistant Deputy Minister of Safety and Security, the TCMSS staff oversee the certification and oversight of all commercial vessels under the CSA 2001.

1.8 Northumberland Ferries Limited operations

TC Programs Group had a charter party agreement with NFL to operate the Holiday Island on its behalf; operations were financially supported through a contribution agreement with NFL that was signed by TC’s Regional Director, Programs, Atlantic Region and NFL’s President and Chief Executive Officer.At the time of the occurrence, the vice-president of marine operations for NFL also acted as the designated person ashore and the customer safety officer, and acted in other roles for Bay Ferries and the vessels associated with their routes. The agreements between NFL and TC stated that NFL “shall act as if it were the ‘authorized representative’ (as defined in the Canada Shipping Act, 2001) of such vessel.”Canada–Northumberland Ferries Limited, Ferry Services Contribution Program, Agreement for Wood Islands, Prince Edward Island to Caribou, Nova Scotia Ferry Service, Section 3.6.3: Safety of vessels. In administrative documents, various people at both TC Programs Group and NFL signed as the AR at different times. Under the DSIP, an AR can authorize the vessel operator to act as the signing authority. When the Holiday Island was enrolled into the DSIP as a fully delegated vessel, TCMSS reminded TC Programs Group that TC Programs Group remained responsible for the duties of the AR, as defined in the CSA 2001.

The agreements between TC and the operator are regularly reviewed and renewed for periods of 1 to 5 years. These agreements included requirements for NFL to

- provide the operations manager at TC Programs Group with quarterly reports about crossings;

- report any incident, accident, occurrence, or deficiency that required communications with organizations such as the RO or MCTS;

- notify TC Programs Group when ferry crossings had to be cancelled for any reason; and

- notify TC Programs Group when emergency repairs were needed.

Emergency repairs were not defined in the agreements but were described internally as any incident that could affect the operation of the ship or a situation that could get worse if ignored. The investigation found 2 notifications from NFL to TC Programs Group in 2022 about a need for emergency repairs. One notification resulted in a repair that caused a delay in crossings. The other notification resulted in a repair that caused cancellations and was related to a system that was part of a capital project.

TC Programs Group, on behalf of the owner, was required to commission an annual vessel inspection; NFL was required to respond to this inspection report. The last annual vessel inspection report for the Holiday Island was produced in 2017. Informal discussions about maintenance continued during site visits and other conversations related to the quarterly reports from NFL (see section 1.14, Maintenance and repairs).

1.8.1 Typical trip

During the tourist season, PEI is a popular destination for travellers, and the demand for travel to the island is high. The Northumberland Strait separates the mainland from PEI; this body of water is significant for tourism and is also an important location for shellfish fisheries, especially lobster. To cross the Northumberland Strait, travellers can use the Confederation Bridge or take the ferry. To accommodate the volume of travellers, NFLBay Ferries, a subsidiary of NFL, operates the ferry route between Saint John, New Brunswick, and Digby, Nova Scotia, and the route between Bar Harbor, Maine, and Yarmouth, Nova Scotia. NFL and Bay Ferries are separate organizations, but many of the administrative tasks are managed centrally and some of the shore staff have a role in both organizations. operated 2 ferries, the Confederation and the Holiday Island, for a total of 8 trips in each direction daily.When it is not the tourist season, NFL operates 1 ferry and makes 3 to 4 trips in each direction daily. Ferries carry vehicles as well as walk-on passengers; some trucking companies use the ferry crossing to shorten the travel distance required for commercial deliveries.S. Bruce, “Plans in the works for extra P.E.I.–Nova Scotia sailings,” CBC News (published 17 June 2016, updated 17 June 2016), at https://www.cbc.ca/news/canada/prince-edward-island/pei-nova-scotia-ferry-mv-holiday-island-1.3640913 (last accessed on 12 May 2025). The number of vehicles that could be loaded on each vessel varied according to the tide.

Throughout the year, the ferry crossing is often fully booked. Delayed or cancelled crossings could result in a long wait at the terminal or could require passengers to use the Confederation Bridge instead. Delayed or cancelled crossings often result in high-profile news coverage.G. Harding, “P.E.I. premier wants 2nd ferry for Caribou–Wood Islands run,” CBC News (published 09 August 2016, updated 09 August 2016), at https://www.cbc.ca/news/canada/prince-edward-island/pei-caribou-wood-islands-ferry-1.3713333 (last accessed on 12 May 2025).

On a typical day, the Holiday Island departed on its 1st crossing from Wood Islands at 0830 and completed the 8th crossing back to Wood Islands around 2115. The Caribou–Wood Islands crossing took approximately 75 minutes.

At each end of the trip, unloading and loading the Holiday Island took between 20 and 30 minutes. Passengers were asked to leave their vehicles during the crossing, and most passengers spent the trip on the boat deck or in the observation area on the housetop deck. At the beginning of each crossing, a safety briefing was broadcast over the PA system.

Passengers could book online, by phone, or when they arrived at the terminal; most passengers booked online.For example, in 2021, approximately 84% of passengers booked (and paid) online, 11% booked by phone, and 5% paid on arrival. Source: Narrative Research, 2021 Northumberland Ferries Limited Passenger Study (February 2022). Passengers travelling with a vehicle purchased 1 ticket for the vehicle and all passengers. Walk-on passengers purchased 1 ticket per person. Whether passengers booked online or at the terminal, they registered with the toll booth operator when they arrived.

1.8.2 Software for booking and reporting travel

Passengers purchased tickets through an online booking form on the NFL website that was created using commercially available software. The website used only some components of the software.The ferry system software includes booking, check-in (terminal), account management, finance, sales, and reporting components, all based on a common database. The form asked the user to select the crossing date and time, identify the number of passengers in each of 4 age groups (over 60, 13 to 59, 6 to 12, or 0 to 5 years old), choose whether the same passengers would be on the return trip (if a return trip was being booked), and add vehicle information. The name and accessibility requirements for each passenger could be entered as well as detailed contact information for the booking contact person. No controls verified that the information entered by passengers, such as the names and numbers of passengers, was accurate. As well, some passengers were unable to enter a different number of passengers on the outbound versus the return segments of round trips.

One report generated by the software was the resource manifest report. This report summarized the bookings and listed the contact details, the number of passengers, and the type of vehicle. The resource manifest report also contained a column for the numbers of passengers and vehicles that boarded; NFL did not use the module that recorded passengers as they boarded the vessel and so this column was empty. The investigation determined that the information from these manifests was not used by the crew.

On the day of the occurrence and in January 2023, TSB investigators requested passenger data for the occurrence voyage. For each request, investigators received a copy of the resource manifest report from the online booking system with different counts in each (230 passengers versus 166 passengers).

1.9 Passenger management

In case of an emergency, crew and passengers need to be appropriately equipped and informed. As the management of passengers on a vessel during an incident brings additional complexity, the regulations stipulate higher standards for construction, equipment, and training on passenger vessels compared with similar commercial vessels. Regulations and guidance also set time limits for completing some emergency procedures. For example, passengers on a roll-on/roll-off vessel must be mustered and counted within 30 minutes of the general alarm sounding, and evacuation cannot take longer than 30 minutes.Transport Canada, C.R.C., C. 1436, Life Saving Equipment Regulations (as amended 20 December 2023), section 111. See also guidance provided in Transport Canada Ship Safety Bulletin 04/2022: Requirements for passenger evacuation and safety (08 February 2022), at https://tc.canada.ca/sites/default/files/2022-02/SSB-04-2022E.pdf (last accessed on 12 May 2025).

To prepare for emergencies, crew members need training as well as access to documented emergency procedures. These procedures must be reviewed and practised regularly to ensure the crew can respond effectively. Passengers need instructions on where to muster in the event of an emergency, where to access life-saving equipment, and how to use that life-saving equipment. Being prepared for how passengers may react in an emergency scenario and having experience in how to manage them is an important element of crew training on passenger vessels.

The vessel’s AR is responsible for ensuring that both the crew and the passengers receive safety training.Government of Canada, Canada Shipping Act, 2001 (S.C. 2001, c. 26) (as amended 22 June 2023), paragraph 106(1)(c). Typically, the master carries out drills for the crew, following the procedures supplied by the AR. The master is also responsible for maintaining records of training and familiarization.Transport Canada, SOR/2007-115, Marine Personnel Regulations (as amended 23 June 2021), section 205.

1.9.1 Passenger count

The Fire and Boat Drills Regulations require that, before a passenger vessel sails, the master is to be provided with the number of persons on board and with details of persons who have declared a need for special care or assistance during an emergency.Transport Canada, SOR/2010-83, Fire and Boat Drills Regulations (as amended 20 December 2023), section 10. An accurate count of all persons on board (passengers and crew members) is important to ensure that everyone on board is accounted for in an emergency. An accurate count is also important for ensuring enough crew and equipment are available.

The passengers were counted by the toll booth operators before they boarded the Holiday Island. Once boarding was complete, a toll booth operator reported the total number of passengers to the bridge. On the occurrence voyage, the toll booth operator reported 182 passengers. As well, the bridge recorded that 2 of the 182 passengers would require assistance in an emergency. The number of children and infants was not recorded.

1.9.2 Passenger management training

The Holiday Island safe manning document for 185-381 passengersThe safe manning document for 1-184 passengers specified that appropriate crew members are to hold relevant specialized passenger safety management and passenger safety management in accordance with sections 205 and 229 of the Marine Personnel Regulations. specified that Specialized Passenger Safety Management (Ro-Ro [roll-on/roll-off] Vessels) training was required for most of the crew,Transport Canada, SOR/2007-115, Marine Personnel Regulations (as amended 23 June 2021), section 229. specifically, the master, chief mate, chief engineer, second engineer, and any crew members who interacted with passengers or who had duties involving cargo. Most of the crew members interacted with passengers, managed passengers at muster stations, or were involved in loading or discharging passengers.

In this occurrence

- the master, chief engineer, second engineer, and 2 other crew members had current Specialized Passenger Safety Management (Ro-Ro Vessels) training;

- the chief mate and 9 other crew members had general passenger safety management training (which was expired for 5 of these 10 crew); and

- the remaining 7 crew members interacted with passengers but had no passenger safety management training.

1.10 Engine systems

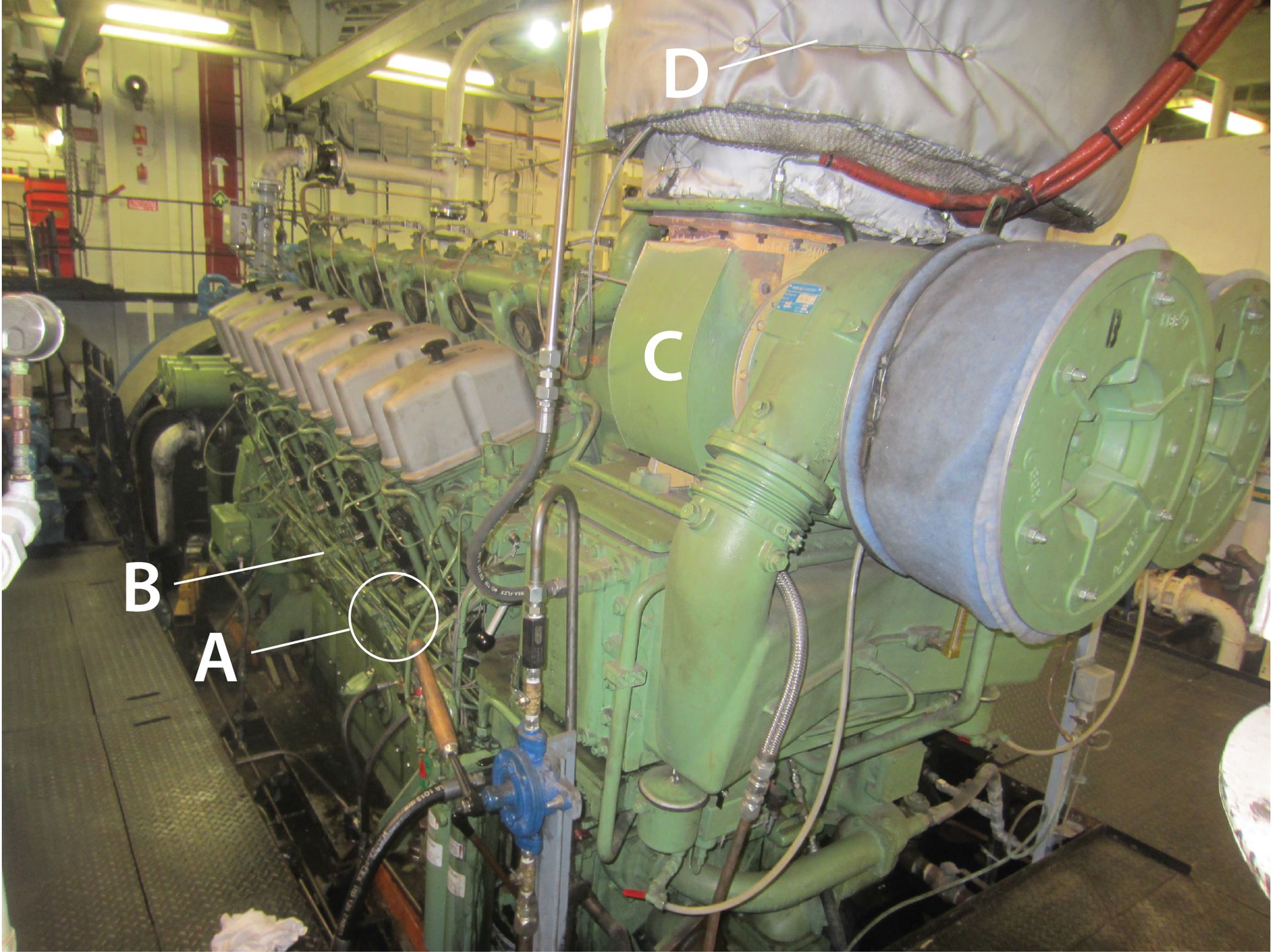

The Holiday Island was equipped with two 12-cylinder Anglo Belgian Corporation marine diesel engines (Figure 6) fuelled by marine gas oil (MGO).Irving, Safety Data Sheet #27944: Marine Gas Oil (18 November 2022). Each engine was cooled by a seawater cooling system.

The engines were replaced in 2014. The vessel was in class and enrolled in the DSIP; the replacement followed both Lloyd’s Register class rules and TC regulations.

Many hot surfaces and potential ignition sources exist in engine rooms and similar spaces (Table 3). To assist in preventing a fire, TC required a means to prevent escaping oil from coming into contact with hot surfaces.Transport Canada, SOR/90-264, Marine Machinery Regulations (as amended 23 June 2021), Schedule XII, Part 1 (Section 4), Item 21. Newer vessels may also be subject to the International Convention for the Safety of Life at Sea (SOLAS), 1974. International Maritime Organization (IMO) guidelines further recommend that all vessels should protect surfaces that can reach temperatures above 220 °C and that may be exposed in the case of a fuel system failure.International Maritime Organization, MSC.1/Circ.1321, “Guidelines for Measures to Prevent Fires in Engine-Rooms and Cargo Pump-Rooms” (11 June 2009), at https://webaccounts.imo.org/Common/WebLogin.aspx?App=IMODOCS (last accessed on 10 June 2025). It is necessary to create a free account to view the circulars.

Location | Temperature |

|---|---|

Exhaust before turbine | 590 °C at 75% load |

Exhaust at each cylinder | 445 to 465 °C at 75% load |

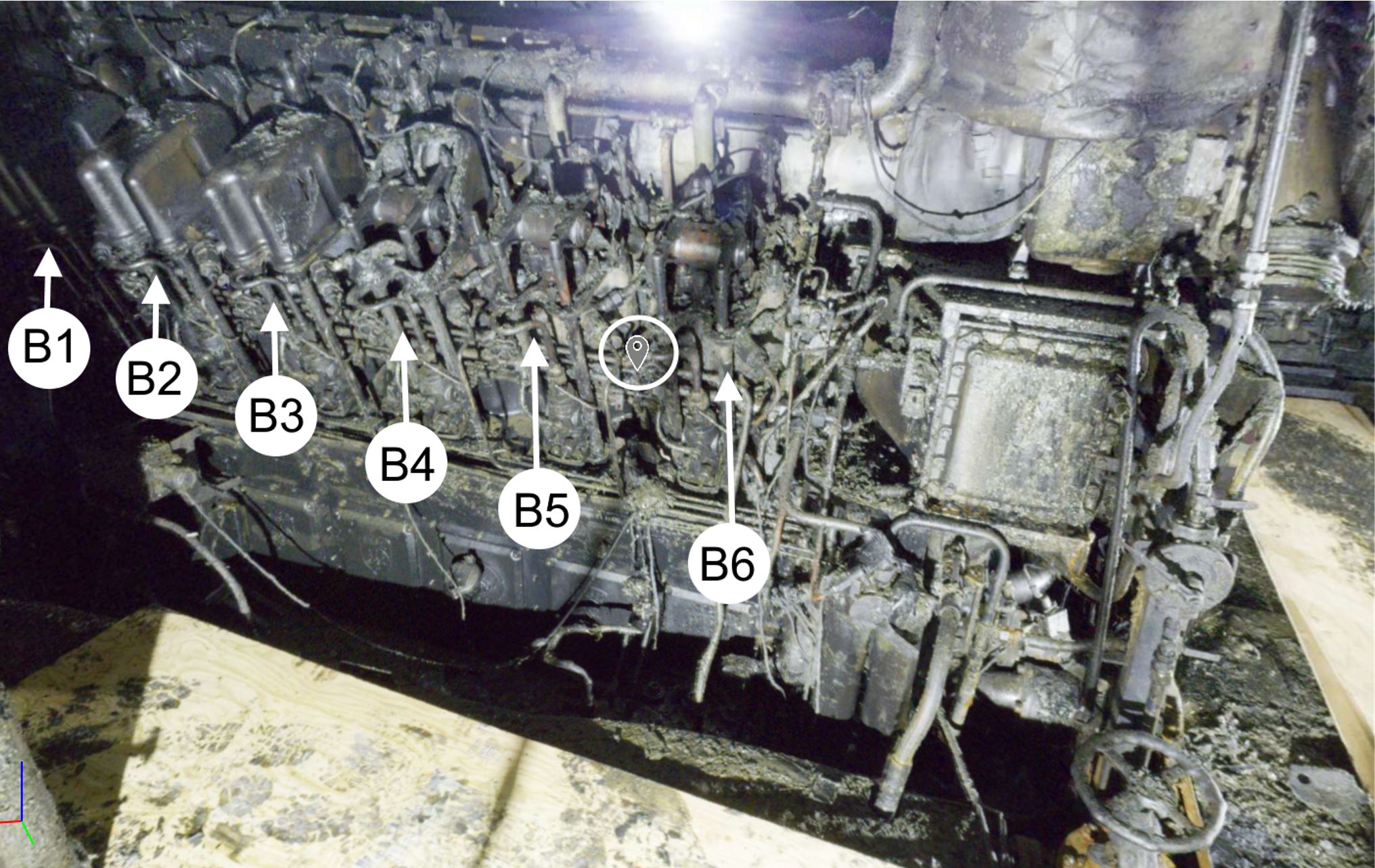

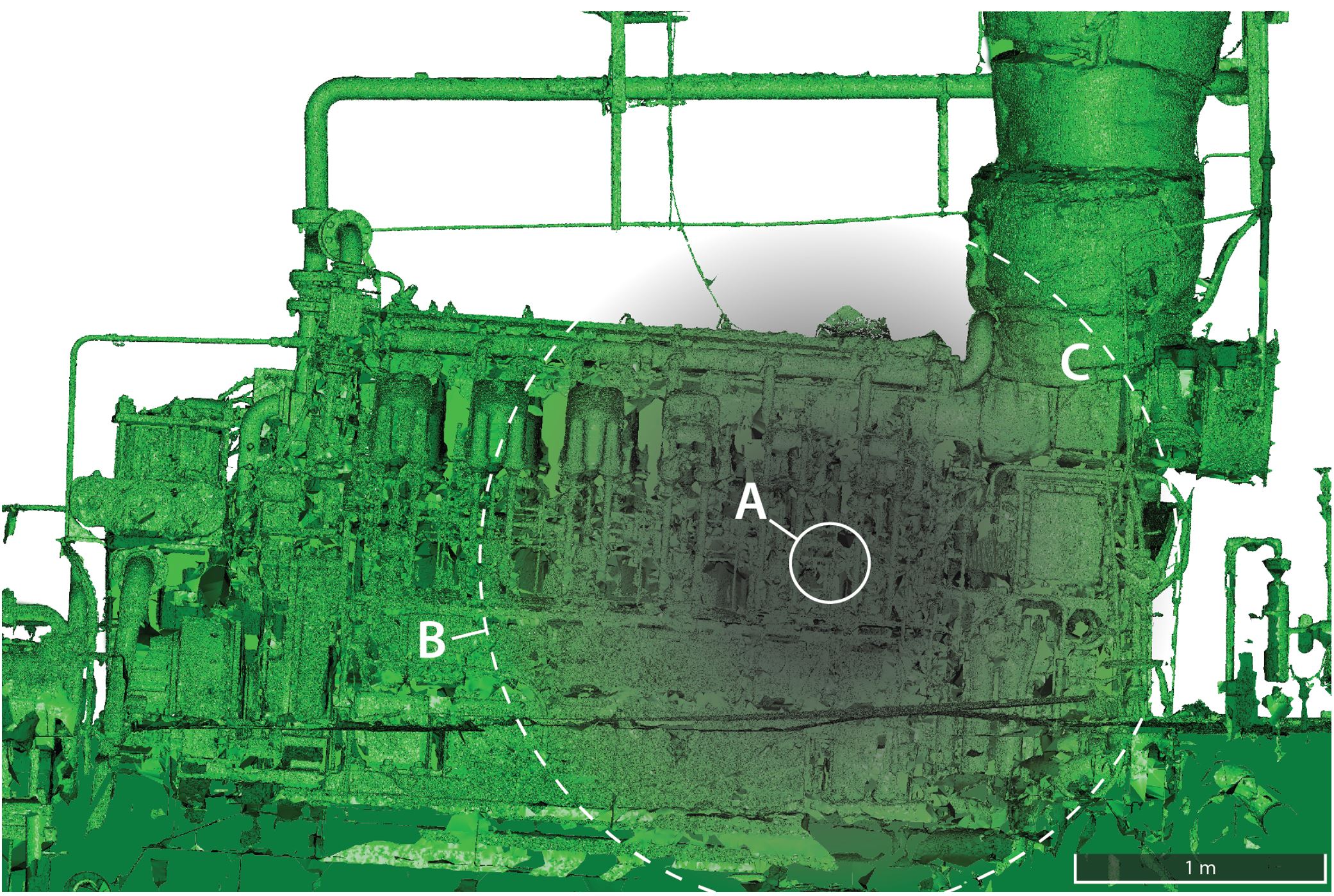

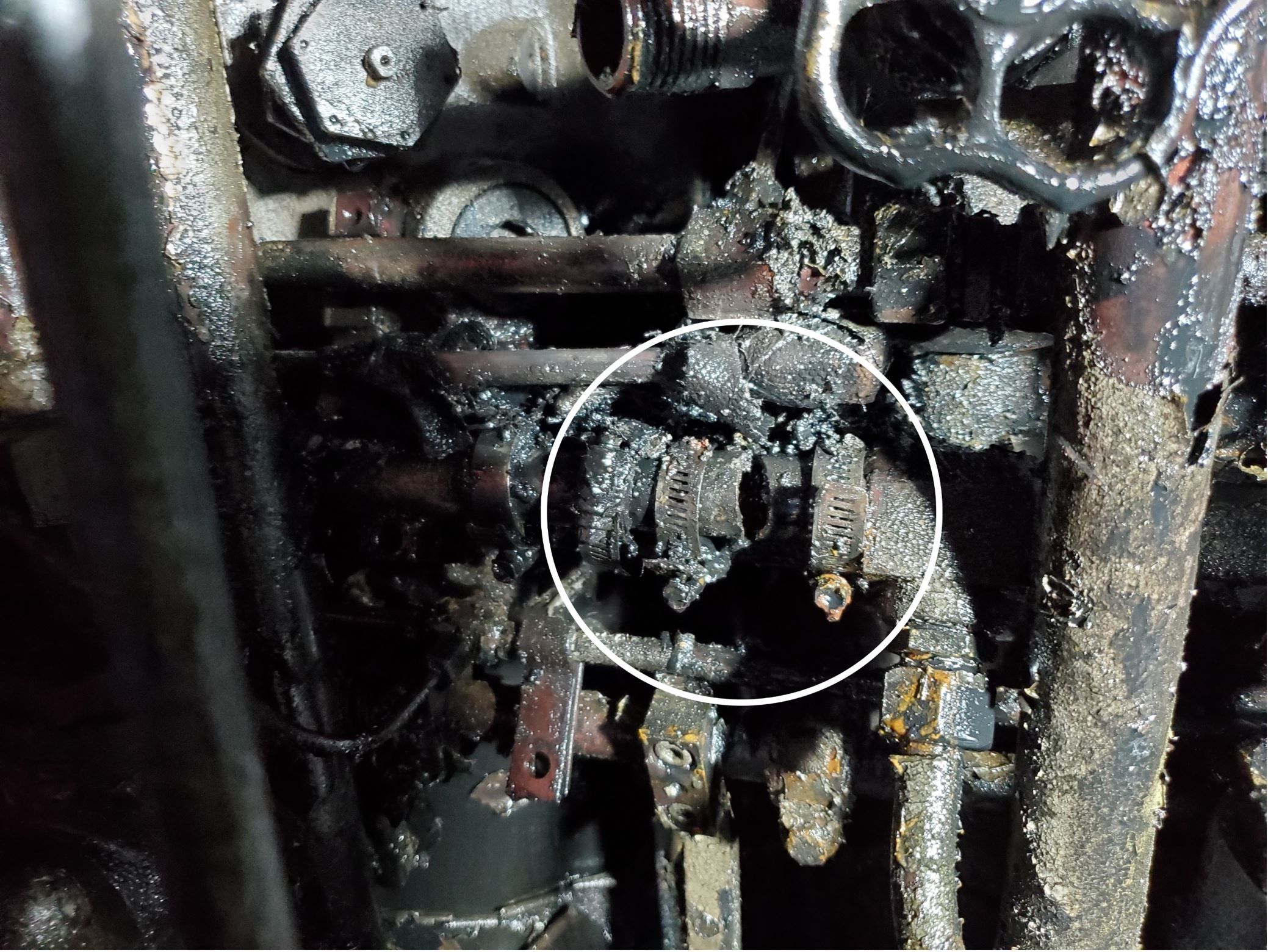

Post-occurrence, the greatest fire damage was observed on the main engine between cylinders B5 and B6 (Figure 7).

1.10.1 Fuel system

Fuel was stored in double-bottomed tanks and transferred to the day tankThe day tank supplied both the main engines and the 2 ship service generators. inside the engine room. The fuel for each engine was gravity-fed from the day tank. The day tank held approximately 5 metric tonnes and was refilled multiple times daily. Post-occurrence, the TSB laboratory calculated that the flow rate of the MGO through a severed forward main engine rail could drain the volume of the day tank within 6 hours. The TSB laboratory concluded that unburned fuel from failures in fuel supply components likely collected in the bilge and supplied additional fuel to the fire.

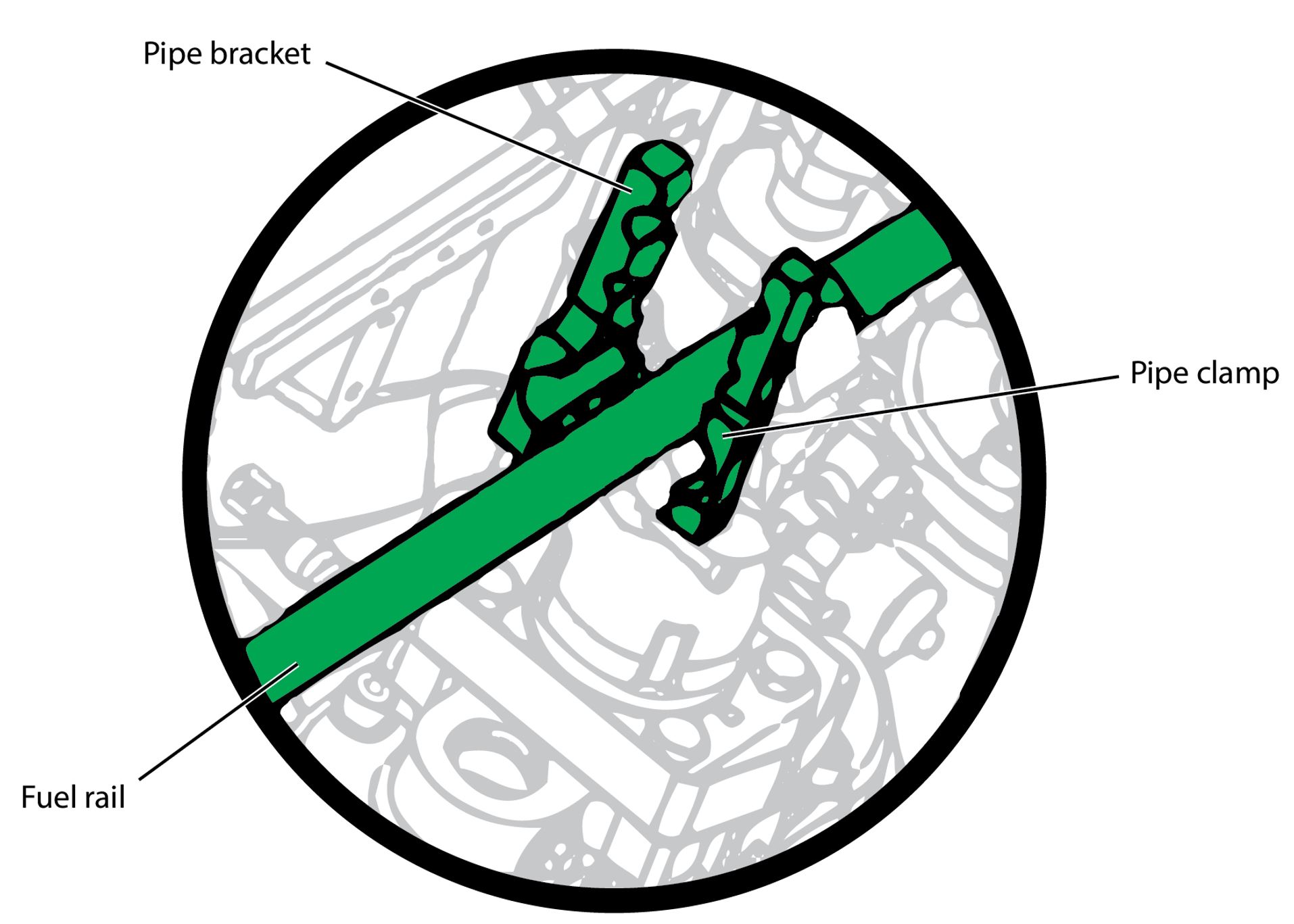

A fuel rail delivered fuel to the fuel injection pump and fuel injector for each engine cylinder. The fuel rail was a 25 mm diameter steel pipe,The fuel rail was manufactured from DIN 2391 ST 35 steel. supported between the cylinders by pipe clamps secured to pipe brackets (Figure 8). The nominal working pressure of the fuel rail was approximately 2.0 to 2.5 bars. The fuel system was last inspected by the RO on 30 May 2021. This inspection included tightness of fittings, fire precaution arrangements (for example, jacketed pipes and their leak detection equipment), flexible hoses, and sounding arrangements. It also included emergency fuel shut-offs and vents.

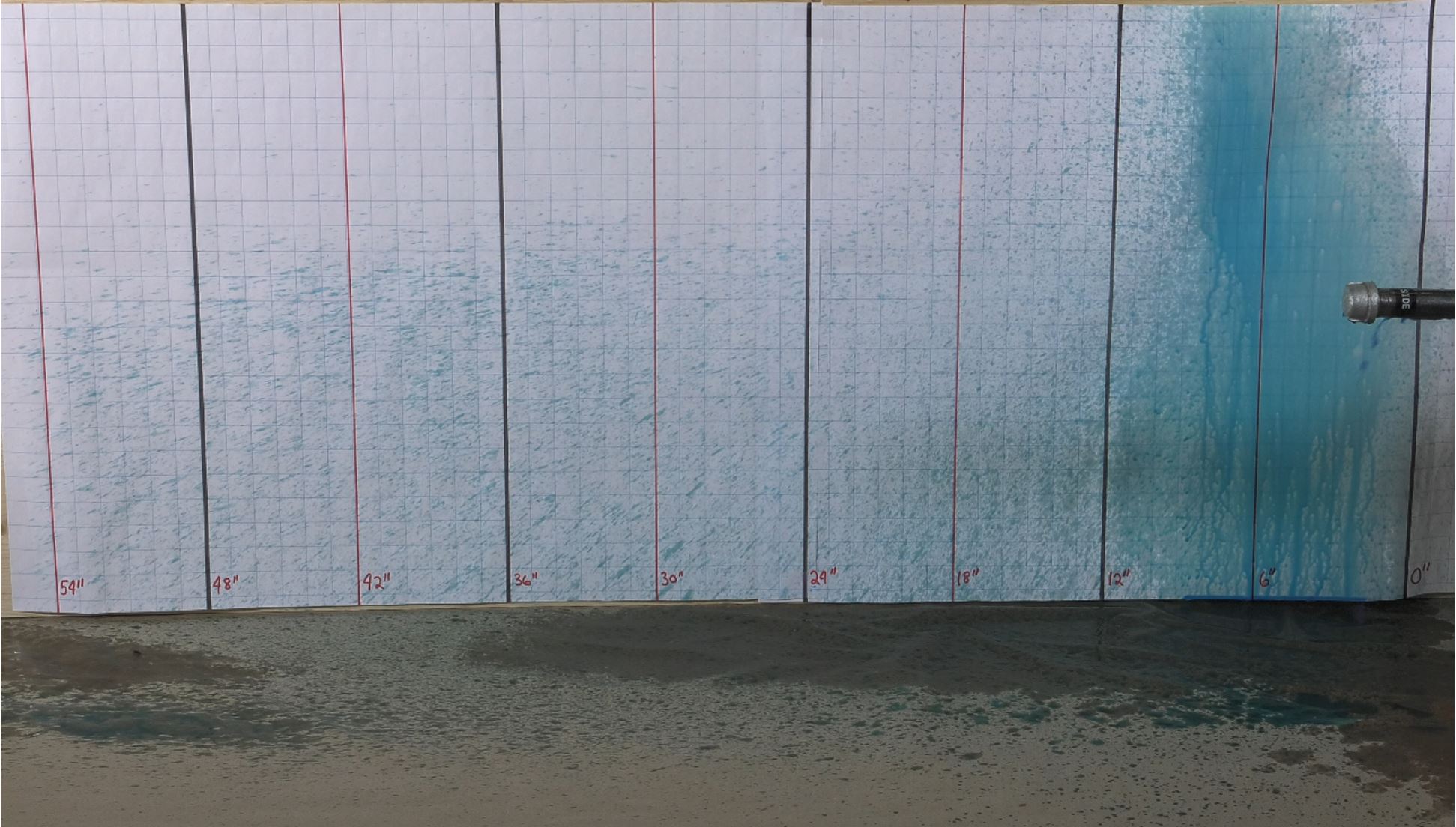

In June 2022, the crew observed a fuel oil leak between cylinders B5 and B6. The source was identified as a damaged location on the fuel rail on the port side of the forward main engine, and a series of temporary repairs was made (see section 1.10.1.2, below). The damaged locationPost-occurrence examination found that the fuel rail was compliant with DIN 2391 ST 35 steel and that no thinning of the fuel rail wall had occurred near the fracture. was within 80 cm of the turbo charger assembly (Figure 9). The TSB laboratory simulated the final temporary repair with the hose clamped onto the fuel rail and exposed it to temperatures and pressures similar to those in the occurrence. This simulation revealed that fuel could be sprayed from under the ends of the repaired, clamped hose, and that this fuel spray could reach distances greater than 137 cm (see Appendix B for details).

Laboratory examination of other parts of the fuel system identified 4 fractures and 1 crackA fracture is a fully failed part while a crack has yet to progress to a fracture. that were present before or during the occurrence fire. The examination also identified 1 crack for which it was not possible to determine the timing.

1.10.1.1 Fuel shut-off valves

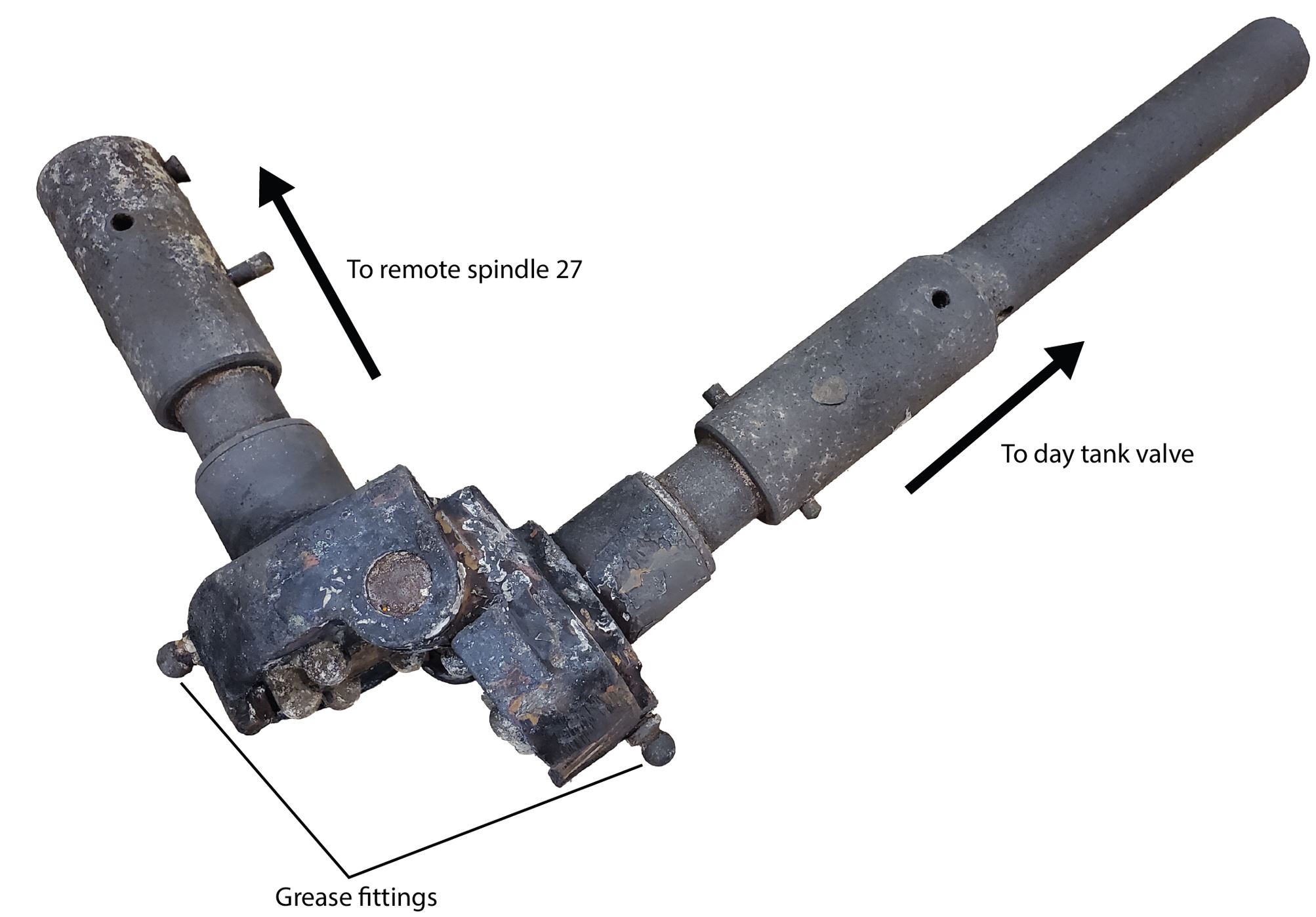

Fuel tanks are required to have shut-off valves that can be closed in an emergency. The day tank on the Holiday Island was equipped with 3 remotely operated fuel shut-off valves: 1 for both main engines, 1 for the generator, and 1 for the engine room heating furnaces. The controls for the remote valves were located forward of the CO2 room on the main deck (Figure 10). When the system was examined after the fire, the control indicators for the main engine and generator fuel shut-off valves were in the open position and the fuel valves were approximately half open. The heating furnace valve was closed and its control indicator was in the shut position.

Each extended spindle arrangement had several linkages between the control and the day tank valve. All of these linkages required regular greasing. For the main engine spindle arrangement, the first 90° knuckle below the main deck (Figure 11) had 2 grease fittings; the grease fitting on the side closest to the main deck was not visible from where maintenance was performed and was difficult to access. During post-occurrence examination onboard the vessel, it was observed that the knuckle was seized and would not turn. A knuckle on the main engine spindle assembly was disassembled and examined by the TSB laboratory. The grease recess in the side of the knuckle closest to the main deck was dry and the valve side, closer to the fire, had retained grease.

1.10.1.2 Maintenance and repairs of the fuel rail

In June 2022, a series of temporary repairs to the fuel rail on the forward main engine began (Table 4). After 2 temporary repairs failed, a replacement fuel rail was ordered.

Date (2022) | Action |

|---|---|

20 June | A fuel oil leak that was identified on the forward main engine was leaking at a rate of 1 drop every few minutes. A 1st repair was made using fuel-rated gasket material and hose clamps. |

28 June | A 2nd repair was made using similar materials. |

03 July | A replacement fuel rail was ordered. An engine manufacturer’s representative offered a patch kit. |

07 July | An engine representative delivered a patch kit. |

19 July | Two more repairs were made (3rd and 4th) using fuel-rated gasket material and hose clamps. |

20 July | A 5th repair was made using similar materials and fuel rail clamps were removed. A contractor applied the repair patch provided by the engine representative; the repair failed immediately. The damage had grown to approximately 75–80% of the fuel rail’s circumference. A 6th repair was made using fuel-rated gasket material and hose clamps. |

21 July | After the 1st trip of the day, the fuel rail was cut fully to slide a section of heater hose over the damaged area. The heater hose was secured with hose clamps. NFL followed up with the engine representative about a delivery date for the replacement fuel rail. |

22 July | Fuel rail brackets were remounted (when the TSB investigated immediately after the occurrence, the fuel rail clamp between cylinders 5 and 6 was missing). NFL received an update stating that the replacement fuel rail was on back order and additional information would be available on 25 July. |

When the damage was first identified, a crew member suggested permanently repairing the fuel rail by removing and welding the damaged section of fuel rail, instead of patching it. External consultants also recommended the same repair. A weld would have required taking the vessel out of service for 1 or 2 days.

On 20 July 2022, the external consultants were directed to apply the patch kit supplied by the engine representative. Fuel rails are installed very close to the engine block, and hard to repair in place. The fuel rail location and the size of the crack meant that not all instructions for applying the patch kit could be followed and this patch failed within minutes.

On 21 July 2022, after the 1st voyage of the day, a temporary repair was made using a section of heater hose, which was made of a material the manufacturer describes as unsuitable for fuel or oil transfer,Dayco, Products Guide (2021), “Coolant Hose,” p. 53. secured with 4 worm drive hose clamps (Figure 12). The next 3 voyages that day were delayed by 1 hour or less and the remaining voyages were on time.

Post-occurrence, the TSB laboratory carried out a series of tests and determined that, with a combination of line pressure, exposure to fuel, engine room heat, engine vibration, and a marginally torqued clamp, a sudden leak could have developed.

1.10.2 Engine cooling system

Each of the Holiday Island’s main engines and auxiliary generators was cooled by an open jacket water cooling system. The jacket water was cooled by seawater through a heat exchanger.

Seawater was brought in through suction piping from below the waterline, passed through the heat exchanger, and discharged above the waterline. The seawater intake could only be closed using hand-operated valves located on the port and starboard sides of the hull in the middle of the engine room.

The seawater cooling system consisted of rigid steel piping with a flexible connection at each intake and discharge point on the engine-driven seawater pumps. These flexible connections isolated the rigid piping and hull from normal engine vibration.

According to both the Marine Machinery Regulations and the technical specifications of the engine replacement contract, when the new engines on the Holiday Island were installed in 2014, the installation was required to meet class rules. Under these rules, the flexible connections installed between the seawater cooling system and the engines, where failure could result in flooding, were to be of a fire-resistant type.Lloyd’s Register Group Limited, Rules and Regulations for the Classification of Ships (July 2022), section 7.3.4. The type approval certificate for the flexible connections fitted on the Holiday Island had a similar requirement.DNV GL, Type Approval Certificate, issued to Elaflex HIBY GmbH & Co. KG (20 February 2020), at https://elaflex.de/dokumente/download/Certificate/Zert_ERV_DNV_GL_ERV.pdf (last accessed on 16 July 2024).

In this occurrence, the flexible connection was not rated as fire resistant and was not protected by a fire-resistant sleeve. Investigators found no record that any deficiency related to the fire resistance of the flexible connection had been noted on the engine replacement plans, at the post-installation inspection, or in subsequent inspections.

Finding: Other

The need for fire protection of the flexible connections between the seawater cooling system and the engine was not identified at the engine replacement planning stage or during post-installation and subsequent inspections.

When the vessel was towed to the dock on 24 July 2022, the engine room was found to be flooded to a level of 3.58 m from the tank top, above the tops of the main engines. The TSB’s post-occurrence examination of the vessel found that the flexible connection between the seawater cooling system and the forward engine was extensively damaged by the fire and was the main source of water ingress. As well, the main seawater intake valves were open.The main seawater intake valves could not be closed until a few days after the vessel was towed to the dock. The flooding stopped once the valves were closed. The port generator had a flexible cooling hose that was also damaged by the fire.

Depending on the type of vessel and voyage, TC regulations may require remote controls for the intake valves of the seawater cooling system. However, a passenger vessel such as the Holiday Island, operating on Near Coastal, Class 2 voyages, was not required to have remote valve controlsTransport Canada, SOR/90-264, Marine Machinery Regulations (as amended 20 December 2023), schedule VIII, sections 23 and 24. and the Holiday Island was not equipped with them.

1.11 Structural fire protection

Statutory requirements for the maintenance of a vessel define a minimum level of safety. Given the high degree of risk posed by fire, vessel construction regulations include requirements for structural fire protection as well as for fire suppression systems and other equipment for fighting a fire, such as portable foam applicators and firefighting suits.

Provisions in new regulations may define exemptions (‘grandfathering’) in terms of the age of the vessel, the date it was registered in Canada, the age of the engine, and so on, but regulations typically require existing vessels to apply new elements that are considered feasible. Any installation of new equipment or machinery or substantial structural modifications must meet the regulations in force at the time.

Therefore, vessels of similar sizes operating in Canadian waters are required to meet quite different construction and equipment requirements, depending on their age.For more detail, see the Regulatory Impact Analysis Statement for the Vessel Construction and Equipment Regulations published in the Government of Canada’s Canada Gazette, Part 1, Vol. 156, Number 44. Because of the date it was built, the Holiday Island was required to comply with the Fire Detection and Extinguishing Equipment Regulations (now repealed) and the Hull Construction Regulations (as amended 02 February 2017).

The Holiday Island engine room was a category A machinery space.“Machinery spaces of category ‘A’ are spaces and trunks to such spaces [that] contain internal combustion machinery used for main propulsion, internal combustion machinery for purposes other than main propulsion where such machinery has in the aggregate a total power output of not less than 375 kW, or any oil fired boiler or oil fuel unit.” Source: Transport Canada, TP 11469, Guide to Structural Fire Protection (1993), Part 1: Definitions, at https://tc.canada.ca/en/marine-transportation/marine-safety/guide-structural-fire-protection-1993-tp-11469-e (last accessed on 16 July 2024). In such spaces, all doors, hatches, vents, and other openings must be airtight when closed and bulkheads and decks must be “A” class divisions.“'A' class divisions are bulkheads and decks constructed of steel or other equivalent material, capable of preventing the passage of smoke and flame to the end of the one-hour standard fire test.” (Source: Ibid.).

1.11.1 Vents and air circulation

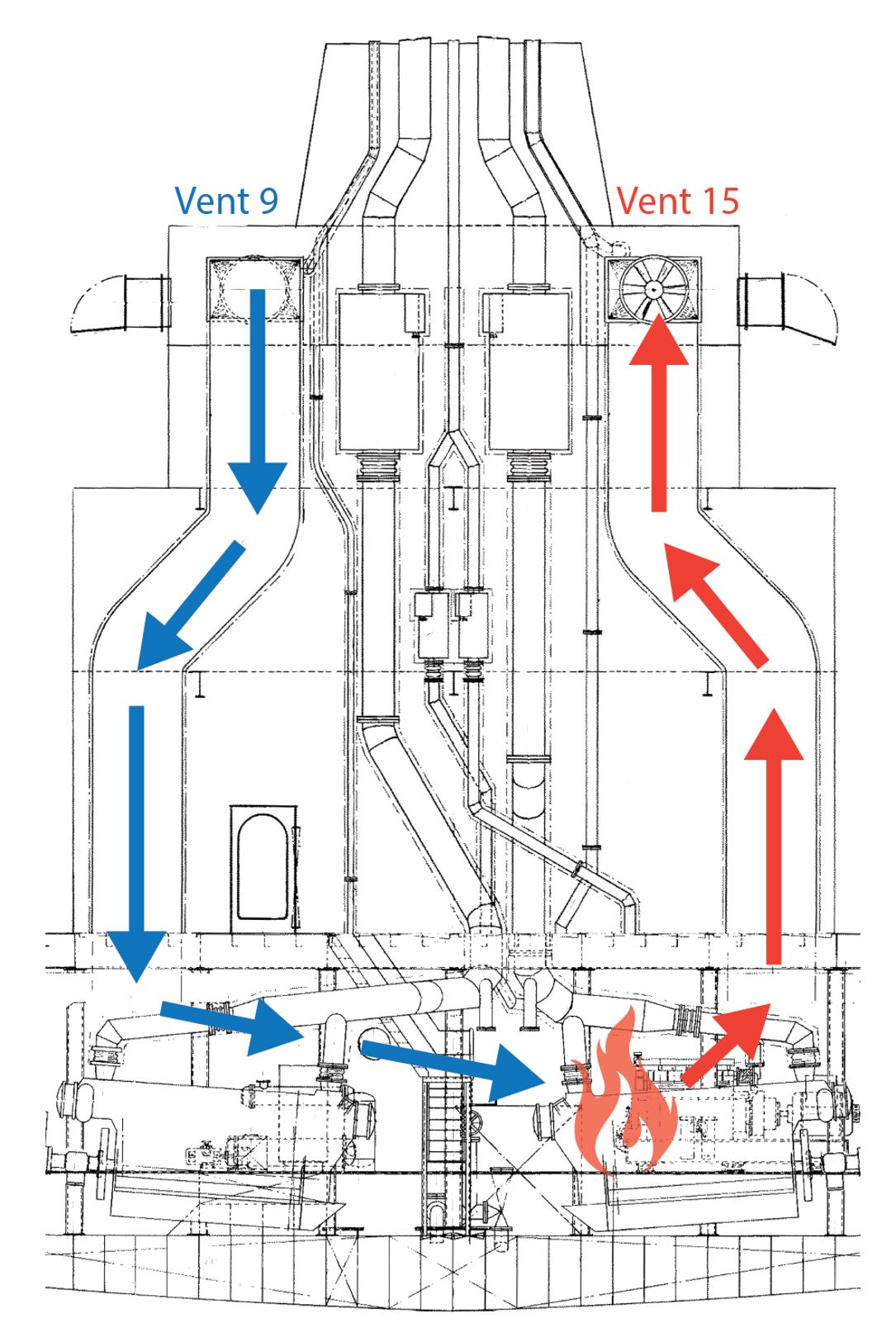

Engine rooms and other machinery spaces are workspaces that require good ventilation during operations, which is provided by a ventilation system that consists of intake fans and exhaust fans. In case of a fire, such a space must be sealed by closing all vents and other openings to limit the availability of oxygen. The Holiday Island’s main engine room had 5 doors, 1 hatch, and 8 vents (2 air intake vents and 6 exhaust vents). Four of the 8 vents were on the housetop deck and 4 were on the funnel deck. The locations of these vents and all other vents were depicted on the fire control plan. Each vent was labelled with a number on the fire control plan and on placards that indicated the open and closed positions for the damper handle (Figure 13). The crew also used an informal document showing the location of the vents on each deck. Not all vents on this document were labelled. For example, only 1 of the 2 main engine intake vents was labelled as such.

The air intake vents for the main engine room, vents 9 and 15 on the housetop deck, closed with louvre dampers. The dampers were accessed from inside the fan room, which was inside the same fire space as the engine room. The location of the dampers met the requirements in the regulations that were in force at the time of the occurrence.Transport Canada, C.R.C., c. 1422, Fire Detection and Extinguishing EquipmentRegulations (as amended 03 February 2017), subsection 8(2). These regulations were repealed in 2017. On newer vessels, damper handles must be capable of being closed from outside the space being ventilated, must operate both manually and automatically, and must pass the requirements for sealing defined in the fire test procedures.Transport Canada, SOR/2017-14, Vessel Fire Safety Regulations (as amended 23 November 2022), subsection 112(1). Vent 15 was installed in a conventional manner: when the vent was in the closed position, the handle was perpendicular to the direction of airflow. Vent 9 was non-standard, and the damper handle operated in the opposite direction. The fact that the operation of vent 9 was non-standard had been noted by the crew in May 2022, following maintenance of the vents, but the vent had not yet been adjusted. The engine room exhaust vents on the funnel deck also closed with louvre dampers.

The vents met requirements at the time the vessel was constructed. Louvre dampers are not capable of completely sealing a vent; solid fire dampers seal more effectively. Planned maintenance on the intake louvre dampers included replacement with similar dampers, not solid dampers.

Finding: Other

The louvre dampers on the air intake vents were being replaced with the same type of damper, which is less effective at sealing vents than solid fire dampers.

Post-occurrence, vents 9 and 15 were both found to be open. As the fire burned under vent 15, hot air flowed out from vent 15, which made it act as an exhaust, and fresh air came from vent 9, acting as an air intake (Figure 14; see also Figure 5).

1.12 Fire safety systems

Vessel construction regulations contain requirements for fire suppression systems and other equipment for fighting a fire, such as portable foam applicators and firefighting suits. Unlike structural systems, most requirements related to firefighting equipment apply to all registered vessels, regardless of age.

Success in fighting a fire depends on the equipment available, the experience of those fighting the fire, and the area of the fire. The larger a fire is, the more likely it is that a manual firefighting response will be unsuccessful and a fixed fire suppression system will have to be used.United States National Fire Protection Association, NFPA 921: Guide for Fire and Explosion Investigations (2024).

1.12.1 Fire alarms

The purpose of a fire alarm system is to detect the presence of fire or smoke and alert the occupants of the vessel, allowing them to evacuate to safety and facilitating a quick response to the fire emergency. Fire detection and alarm systems may have an event log to capture when the heat and smoke sensors and CO2 pilot cylinders are activated. The International Code for Fire Safety SystemsInternational Maritime Organization, International Code for Fire Safety Systems (IMO Publishing, 2016), Chapter 9: Fixed Fire Detection and Fire Alarm Systems, Section 2.5.1, Visual and Audible Fire Signals. specifies that a means to manually acknowledge all alarm and fault signals must be provided at the control panel. The code also specifies that it must be possible to manually silence the audible alarms on the control panel and indicating units.

In this occurrence, the bridge crew activated the PA system as a workaround to silence the fire alarm. When they were notified that bridge conversations were being broadcast, they covered the microphone with a cloth. The investigation was unable to determine why the fire alarm could not be silenced.

1.12.2 Firefighting equipment

Firefighting equipment is carried on vessels to fight fires and protect crew. Firefighting equipment includes fixed fire suppression systems and portable equipment to fight small fires. The required firefighting equipment on board the Holiday Island included firefighting suits and equipment for the bridge fire team and the engine room fire team.

Water was supplied to the 38 fire hydrants through a network of pipes by multiple fire pumps, bilge pumps, and emergency pumps located below the main deck. As well, portable foam applicator firefighting equipment was stored on the forward main deck and the aft upper deck. The emergency generator and the pumps worked throughout the occurrence, and boundary cooling continued until the vessel was completely evacuated.

The safety data sheet for the marine gas oil (MGO) used on the Holiday Island lists alcohol-resistant foam, water fog, dry chemical powder, and CO2 as suitable firefighting agents.In the Guide for Land-Based Fire Departments that Respond to Marine Vessel Fires (NFPA 1405, section 12.10.8.5), the U.S. National Fire Protection Agency also states that the preferred agent for fighting a fire in the main engine room is foam. The safety data sheet warns against using jets of water, because this spreads the fire.Irving, Safety Data Sheet #27944 (18 November 2022), Marine Gas Oil (3095). The same considerations apply to fuel that might be released from vehicles carried on the ferry.

1.12.3 Carbon dioxide fixed fire suppression systems

CO2 is a colourless, odourless inert gas. It is non-flammable and non-conductive. CO2 is often used for fire suppression in category A machinery spaces such as engine rooms and in other confined spaces, such as cargo holds.

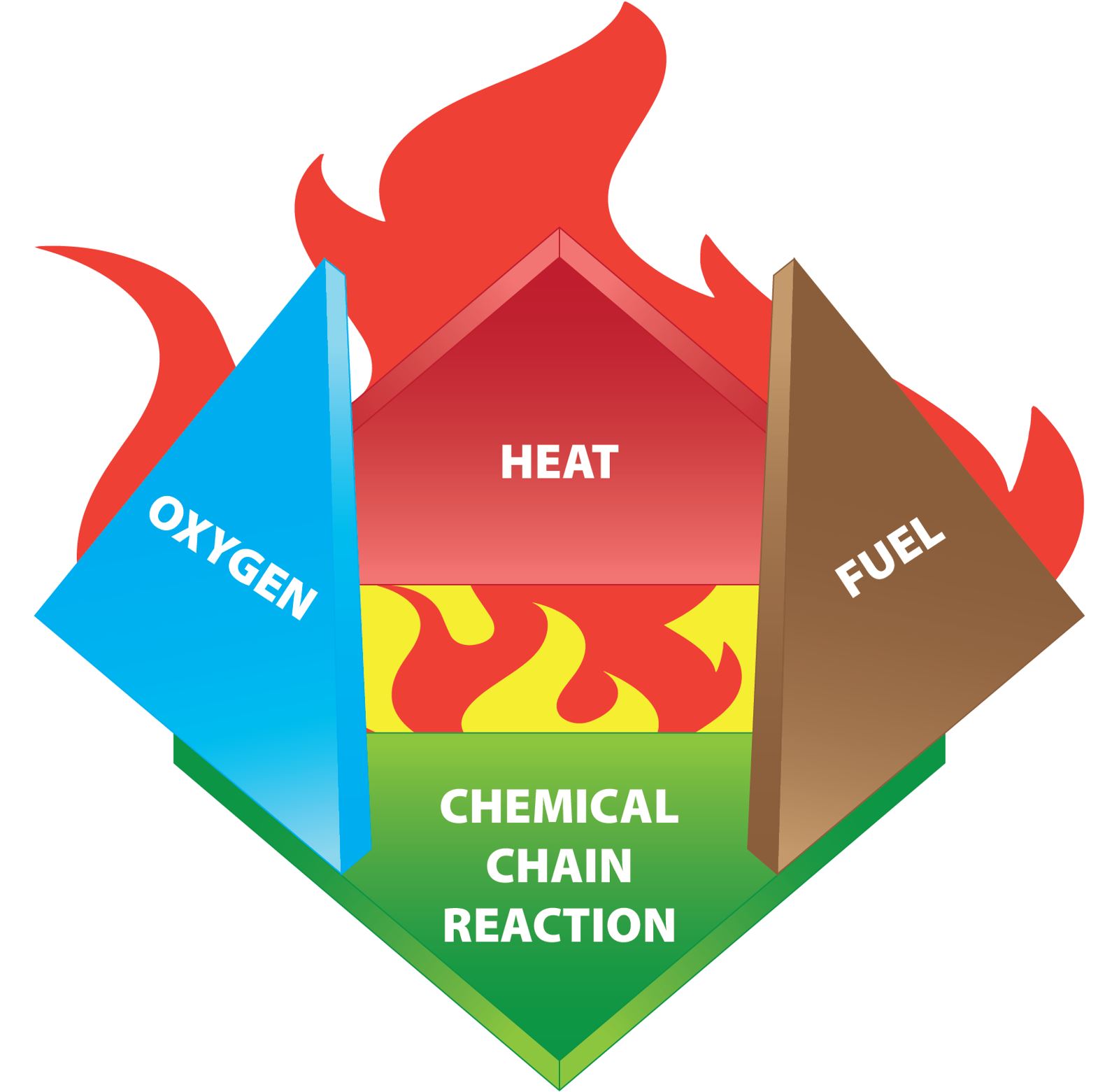

When applied to a fire, CO2 provides a heavy blanket of gas that displaces the oxygen to a point where combustion cannot occur. Proper sealing of the space where the CO2 will be released is essential to effectively extinguish the fire. CO2 is less efficient at cooling than water or other fire suppressants.

After the decision to use a CO2 fixed fire suppression system is made, a number of preparatory steps must be carried out to ensure the crew is safe and the CO2 release is effective:

- confirm all personnel are present and out of the space,

- seal the space (ensure vents, fire dampers, and access points are closed),

- close any oil and fuel valves,

- confirm that all machinery inside the space is stopped, and then

- activate the release of CO2.

When the system is activated, a warning alarm sounds in the protected space. At the same time, a signal is sent to the fire alarm system that indicates that CO2 has been released and gives the location of the protected space. After a brief delay, the CO2 release begins and within a few minutes, cylinders are emptied. After use, the components must be recharged, replaced, or reset by qualified technicians.

After CO2 has been released, the space must be cooled and ventilated before it is safe to re-enter. Ventilation of the space should not be started until it has been established both that the fire has been extinguished completely and that conditions are no longer sufficient for the fire to restart. Critically, the space must remain sealed until the temperature has cooled below the self-ignition point of any remaining fuel. If a space is re-entered too early, the fire may reignite and backdrafts may occur.Government of the United Kingdom, Marine Accident Investigation Branch, Safety Digest: Lessons from Marine Accident Reports No. 2/2017 (October 2017), at https://assets.publishing.service.gov.uk/media/5e81e5d2e90e0706fba5421d/2017-SD2-MAIBSafetyDigest.pdf (last accessed on 15 May 2025). Boundary cooling can be used to reduce the temperature of the space more quickly.