Main-track collision

between

Canadian National train no. 417

and Canadian National train no. 342

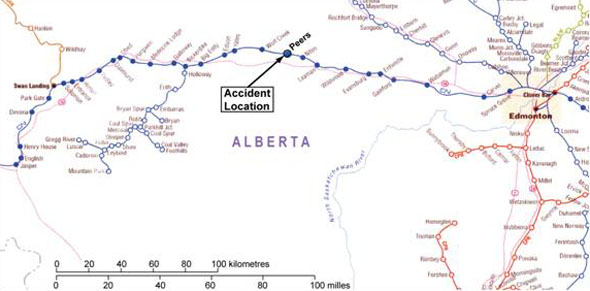

Mile 112.1, Edson Subdivision

Peers, Alberta

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 27 October 2007 at 0505 mountain daylight time, the crew on Canadian National (CN) train A41751-26 (Train 417) operating westward on the main track of the Edson Subdivision initiated an emergency brake application approximately 475 feet from a stop signal at the west end of Peers, Alberta. The train was unable to stop prior to passing the signal and collided with eastbound CN train M34251-26 (Train 342) that was entering the siding. As a result of the collision, Train 417's locomotives and 22 cars derailed. Ten other cars sustained damage but were not derailed. Five cars on Train 342 derailed and four other cars sustained damage but did not derail. There were no serious injuries and no release of dangerous goods.

Ce rapport est également disponible en français.

Factual information

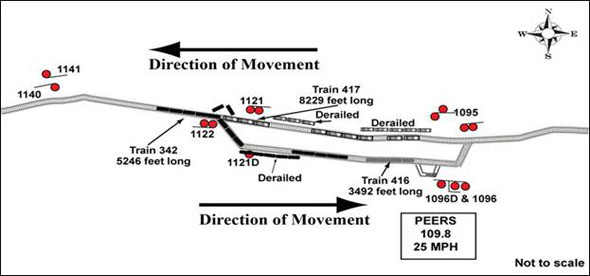

On 27 October 2007 at 0448 mountain daylight time,Footnote 1 eastbound Canadian National (CN) Train 41651-26 (Train 416) had stopped clear of the main track in the east end of the siding at Peers, Alberta, to lift some cars. The siding at Peers is 13 281 feet in length. At 0501, Train 417 proceeded westward on the main track past a permissive signal at the east end of Peers at about 36 mph. About one minute later, eastbound Train 342 proceeded past a permissive signal (restricting) at the west end of the siding at Peers and began entering the siding behind Train 416. At 0505:20, Train 417 rounded the right-hand curve where the stop signal at the west end of Peers came into view. The crew noted that the tail-end of Train 342 had not yet cleared. They made an emergency brake application, but struck the side of Train 342 at about 30 mph (see Figure 1).

Prior to accepting the signal at the east end of Peers, the crew on Train 417 had called out its indication (clear to stop) to each other and announced the indication over the radio. There was a proper progression of signals and the west end of Peers displayed a stop signal. The conductor did not question the locomotive engineer's train-handling decisions.

Train 417's locomotives (CN 2597 and CN 5244) came to rest upright but leaning at approximately 45 degrees in a ditch north of the track. (Photo 1 shows the position of the derailed lead locomotive after it came to rest.) Twenty-two cars, the 3rd to 5th, the 13th to 18th, and the 22nd to 34th, derailed. Ten cars, the 6th to 12th and 19th to 21st, also sustained damage.

Four cars from Train 342 (the 35th and the 45th to 47th cars) sustained damage in the initial collision. Train 417's abrupt stop caused an additional collision between the two trains further east as derailed cars from Train 417 contacted Train 342, derailing 5 cars (the 26th to 30th cars). Figure 2 shows the track layout and location of derailed equipment.

After the collision, Train 417's crew contacted the Rail Traffic Control Centre (RTCC) and were instructed to obtain more details of the damage and report back. The crew climbed out of the damaged locomotives, walked the accident site, and reported the extent of the damage.

Approximately one hour after the accident, a railway manager arrived on site. The manager discussed the accident with Train 417's crew and subsequently sent them for drug and alcohol testing. The tests results were negative.

Weather information

The weather was mainly clear with winds from the south at 17 km/h and a temperature of −3.°C. Twilight conditions existed at the time of the accident.

Train information

Train 417 comprised 2 locomotives, 82 loaded cars, and 43 empty cars (including 1 special dangerous goods car and 22 dangerous goods cars that were not directly involved in the collision). The train weighed 11 161 tons and was 8229 feet in length.

Train 416 was powered by 2 locomotives, comprised 34 loaded cars, 22 empty cars (including 14 dangerous goods cars), weighed 5160 tons, and was 3492 feet in length.

Train 342 was powered by 2 locomotives, comprised 71 loaded cars, 0 empties, weighed 9179 tons, and was 5246 feet in length.

Crew information

The crew of Train 417, a locomotive engineer and a conductor, came on duty at 2015 on 26 October 2007 at Walker Yard in Edmonton, Alberta, Mile 0.0, Edson Subdivision. The locomotive engineer was qualified and was very familiar with the Edson Subdivision. This trip was the conductor's first after having qualified as a conductor.

The crew of Train 342, a locomotive engineer and a conductor, came on duty at 0330 on 27 October 2007, at Edson, Alberta, Mile 129.6, Edson Subdivision. All employees were qualified for their respective positions and met company and regulatory fitness and rest standards.

Edson Subdivision

The Edson Subdivision is comprised of single and double main track between Mile 2.5 (Procyk), just west of Edmonton, and Mile 235.7 (Jasper). Train movements on this subdivision are governed by the Centralized Traffic Control (CTC) method of train control, as authorized by the Canadian Rail Operating Rules (CROR). The subdivision is supervised by a rail traffic controller (RTC) located in Edmonton, Alberta.

The authorized timetable speed in the vicinity of the accident was 65 mph for freight trains and 70 mph for passenger trains. At the time of the accident, there were no temporary slow orders in effect within the immediate area.

Typical daily traffic levels on this portion of the Edson Subdivision included 1 passenger train, 28 freight trains, 1 switching assignment, and 4 yard assignments that briefly enter the main line at different locations.

Train control systems

Train control systems provide for the safe operation of trains, track work, and maintenance on one or more main tracks. CTC is the preferred method of rail traffic control used by railways in Canada.

CTC uses track circuits in the field and displays track occupancies on the RTC's screen. This system provides signal indications to train operators as to the speed at which they may operate, how far they are permitted to travel, or that the blockFootnote 2 ahead is occupied. When a track occupancy appears on the RTC's screen, it normally indicates the presence of a train.

When an RTC requests signals for trains, the signal system determines how permissive the signals will be. CTC allows RTCs to watch a train progress along blocks in a subdivision. However, it does not display the train's exact location within a block; it displays what block the train is in. CTC does not provide any indication that a train may be about to pass beyond an authorized point.

The United States (U.S.) National Transportation Safety Board has noted Positive Train Control (PTC) on its "most wanted list" of safety improvements since 1990. Also, the U.S. Federal Railroad Administration has been pushing forward its implementation on a number of different railways within the U.S. PTC refers to technology that can prevent situations such as train collisions and overspeed derailments.

Several different prototype PTC systems exist that can operate as independent methods of train control. However, most of them focus on enhancing a previously existing method of operation. For example, train crews are alerted by PTC to potentially dangerous situations such as approaching a stop signal too quickly. If an adequate response is not generated by the crew, PTC has the capability of intervening to automatically brake a train if it senses a potential collision. There has been a pilot project on a Canadian federally regulated railway, the Quebec North Shore and Labrador Railway, using a proximity detection device (PDD) that provides similar defences to those provided by PTC by issuing a penalty braking application when the vehicle operator fails to act or does not properly acknowledge the alert warning status. However, no system has been implemented on a Class I Canadian railway.

Work/rest rules and fatigue

The Railway Association of Canada's Work/Rest Rules for Railway Operating Employees (work/rest rules), effective 29 June 2005, section 5, indicate, in part, that after eight hours off duty at the home terminal exclusive of call time when entering road service, the 12-hour maximum continuous on-duty time clock will be set to zero.

However, under running trade employee collective agreements, when rest is requested (giving at least three hours notice), a crew member so requesting must be in and off duty (at a rest facility) prior to the expiration of 10 hours. This request must also include the number of hours of rest required. It also states that train service employees are to be the judges of their own condition.

Section 5.2 of the work/rest rules states that "Operating employees who go off duty after being on duty in excess of 10 hours will…at other than the home terminal – be subject to at least 6 continuous hours off duty, 'exclusive' of call time if applicable."

Between October 12 and 24, the locomotive engineer worked seven shifts on Train 417 that were predominantly ordered during daylight hours (1215 - 1515). He worked an average of eight hours per shift and typically was off duty before midnight. In addition, he worked another eight shifts on various other trains, with a wide range of ordering times. He was previously off duty in his home terminal (Edmonton) on 25 October at 2100, went to bed at approximately midnight, and awoke at 0700 the next morning.

Under the work/rest rules, alertness on duty is a shared responsibility. Employees have the responsibility to properly prepare themselves so as to report to work rested. The company must provide employees with an adequate avenue to obtain such rest. As such, the locomotive engineer called the crew office at least twice that day to obtain an estimate of Train 417's ordering time and was provided with two very different estimates; this resulted in him being unable to plan an effective nap. En route napping is not permitted. He was awake all day and reported for Train 417 at 2015. Assigned crews are expected to protect their assignments indefinitely. The conductor went off duty on 25 October at 1800, went to bed at approximately 2330 and awoke at 0715 the next morning. He napped between 1300 and 1430, and then reported for Train 417 at 2015. When the crew came on duty, they both felt rested for work and were required to work up to 12 hours. At approximately 0315, the crew wanted to ensure that they were off duty within 10 hours of being on duty and, as per the collective agreement, submitted a rest message.

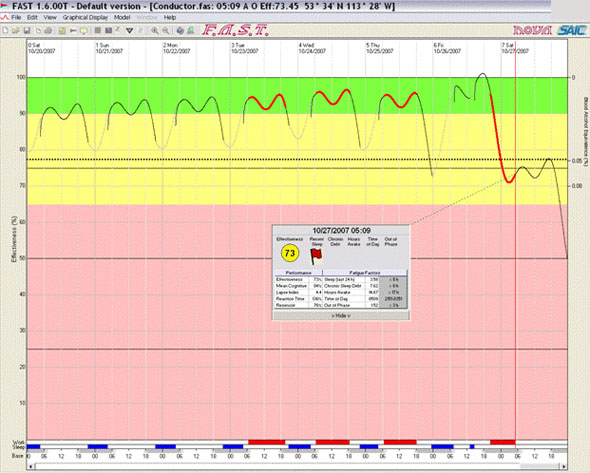

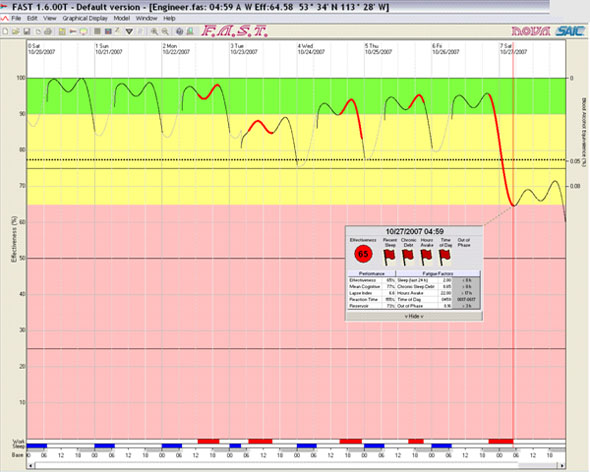

Fatigue and performance levels can be estimated using the Fatigue Avoidance Scheduling Tool (FAST).Footnote 3 This software employs the Sleep, Activity, Fatigue, and Task Effectiveness (SAFTE)Footnote 4 mathematical model and sleep-wake schedule data to predict fatigue factors that are likely to increase the risk of human error and specific human performance metrics. The FAST results are never used as a single tool of fatigue measurement. They are compared to the current state of the scientific literature and validated against facts gathered throughout the investigation. This approach ensures a reliable estimate of fatigue and human performance. Fatigue level results for the crew of Train 417, using this approach, are included in the Analysis section.

In a number of past TSB investigations (such as reports R95V0218, R98V0183, R03W0169, and R05C0082), fatigue was cited either as a cause, contributing factor, or a finding as to risk. In 1995 Canadian Pacific Railway (CPR), CN, and VIA Rail Canada Inc. (VIA), the Brotherhood of Locomotive Engineers, and Circadian Technologies Inc. developed, implemented, and tested an alertness assurance process (CANALERT '95). Various pilot projects with train crews were carried out. Fatigue countermeasures were developed for railway freight operations. They included the creation of circadian time pools that provided regular and predictable work-rest patterns, recuperative napping practices, improved bunkhouse sleeping accommodations, provision of headsets with music and intercoms, and adjustments to railway lifestyle programs. At the end of the pilot project, it was concluded that adopting only one of these countermeasures would be insufficient. However, by adopting a combination of them, fatigue could be reduced. Not all of these measures were adopted, but some freight railways did create circadian time pools, allow restorative rest en route, and improve bunkhouse sleeping accommodation.

One railway, the Quebec North Shore and Labrador Railway, implemented many of the countermeasures which continue to be in place. Additionally, CPR upgraded the quality of all of its bunkhouses system-wide and implemented many of the CANALERT countermeasures on its Laggan pool west of Calgary. CPR is also in the process of testing a fatigue management pilot project in Portage, Wisconsin using a fatigue management software application developed in Australia.

CN has a General Fatigue Management Plan for Rail Operating Employees, Canadian Lines, revised in 2005 and currently in effect. The following is a partial list of the fatigue countermeasures outlined in this plan that are relevant to this investigation:

- assigning crews to specific trains; and

- educating employees by promoting awareness of the physiological and psychological effects of fatigue and the personal countermeasures each individual can take in their daily lives.

In conjunction with CN's fatigue countermeasures, the locomotive engineer was assigned to work Train 417 from Edmonton to Edson on a regular basis. On arrival in Edson, he became accustomed to booking the maximum allowable rest (eight hours), ensuring he could obtain as much rest as possible (typically during the night time) prior to being called for the next available train after the expiration of his rest. However, as Train 417 was rarely ordered at the same time of day in Edmonton, it was difficult for the engineer to adequately plan his sleep in his home terminal. Including the day of the accident, his orders for the last eight trips on Train 417 all came at different times, ranging between 1215 and 2015. The standard notification given to a crew of a train's ordering time is two hours.

ResearchFootnote 5 by Dawson and Reid (1997 a,b) indicates that those who have been awake for 18 to 27 hours reliably exhibited performance decrements that were equivalent to having a blood alcohol content (BAC) of 5 per cent (0.05) or greater (see page 54 of footnote reference number 4). In Canada, a person is considered to be legally impaired when operating a motor vehicle with a BAC level of 0.08. At the time of the accident, the locomotive engineer and conductor had been awake for 22 and 14.5 hours respectively. The FAST model also references effectiveness to blood alcohol equivalence.

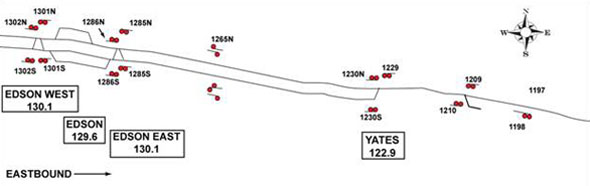

Just prior to the accident, the locomotive engineer formed a mental model that he was actually two stations away, in Yates, about 13 miles further to the west, where there are also two tracks (see Figure 3). The double track that commences at Yates continues for 12.8 miles, whereas the siding that commences at Peers extends for 2.6 miles. The distance between the first two signals encountered for westbound trains is 3.6 miles at Yates as compared to 2.6 miles at Peers.

Reporting fit for duty

According to the work/rest rules, fatigue management is a shared responsibility. Crew members must report fit for duty and railway companies must provide employees an adequate opportunity to fulfill this requirement. Train 417's crew reported for work "fit for duty", which means reporting rested and prepared to maintain alertness for the duration of the tour of duty.

On 12 October 2005 the railway issued Bulletin 37769 to all terminals in western Canada stating, in part, that "when reporting for duty running trade employees must be fit and rested. Effective immediately, crew dispatchers will no longer be permitted to book running trades employees ‘unfit' and this status will be removed from the system."

While personal leave days are available to crew members, such requests must be accommodated by the company well in advance of the day required, subject to the availability of personal leave days allotted for the terminal per day. If crew members obtain an adequate amount of sleep, wait all day for their assigned train to be ordered, and become fatigued again before being called for duty, taking a personal leave day is not an option. The remaining options available to employees are to miss the call or declare themselves sick. In such cases, the railway commonly investigates and may issue discipline.

Training requirements for railway operating employees

CN requires that trainee conductors pass a number of pre-employment screening tests to ensure candidates meet Transport Canada's Railway Employee Qualification Standards Regulations (SOR) (1987).Footnote 6 As such, to work as a qualified conductor on CN, the following are required:

- Five weeks of technical classroom training including the CROR, railway radio regulations, train marshalling, air brakes, freight car and train inspection and components covering first aid, passenger train evacuation, and dangerous goods;

- Thirty training shifts in yard service; and

- Fifteen training road assignments.

Following each of the 45 training shifts, the working conductor accompanying the student conductor is expected to complete an evaluation report. This report is used to identify areas of weakness that may require additional training prior to qualification. If required, an undetermined number of additional training shifts are provided. The railway had records of 27 of the 45 required training evaluations for Train 417's conductor prior to his qualifying as a conductor (the majority completed while working as a yard foreman and not as a main-line conductor).

There are no CN or Transport Canada requirements indicating a minimum number of training trips required to ensure adequate familiarity on each subdivision prior to working the territory as a conductor without a trainer. Additionally, there is no area designated on the student evaluation form concerning subdivision familiarity.

After as few as 45 shifts, employees could be qualified as brakemen, helpers, foremen, or conductors. A helper works in the yard and is under the direction of a foreman. A brakeman would work on main-line jobs accompanied by a conductor and engineer.

A newly-qualified conductor could work immediately without gaining experience as a brakeman /helper which would normally provide additional experience before working as a foreman/conductor. During the last few years, trainees have been designated as qualified conductors/yard conductors prior to a six-month period without concurrence of the designated trainer(s). In the past, it had become common practice that if the railway needed trainee conductors to commence work before completion of their training, the designated union trainer would suggest the use of trainee conductors who had demonstrated above-average ability. In

the later part of 2007, this process appeared to have changed. If no exceptions were noted by the designated trainer, the railway considered all conductor trainees qualified to work before completion of the six months and without the concurrence of the designated trainer.

Train 417's conductor started SOR training in March 2007 and completed it in July 2007. The designated trainer took no exception to his performance during training. The railway considered him to be a fully qualified conductor within four months.

Five months prior to the accident, in May 2007, the conductor completed four training trips over the Edson Subdivision. He worked as a trainman on various jobs from 28 July 2007 until the day prior to the derailment.

Remaining on duty after a traumatic event

High levels of stress are known to reduce performance on judgment and decision-making tasks.Footnote 7

The Journal of the American Academy of Psychiatry and the Law published an article which states, in part, that locomotive engineers can experience psychological trauma when trains strike other trains. Drivers can experience feelings of helplessness, horror, guilt, and anxiety. Although some drivers experience stress disorder or post-traumatic stress disorder (PTSD), their conditions are not always acknowledged within the occupational setting.Footnote 8 The article states that although PTSD may not be immediately evident, its development may be minimized if appropriate action is taken in the hours, days, or weeks after a traumatic event.Footnote 9

An international literature review of PTSD amongst rail workersFootnote 10 demonstrated that it is important to determine if employees are fit to continue work after their involvement in a traumatic event. Post-incident support to employees was also recommended.

For this accident, a radio conversation between Train 417's crew and the RTC was used to provide an initial assessment of the crew's status. In the absence of reported injuries, the crew was tasked to inspect the train and report on damages. At this time, Train 416's crew was at the east end of Peers switching and Train 342's crew was on the head end of their train in emergency after being struck. The available crew members from these two trains were not requested to assist Train 417's crew post accident.

Advance information about train meets

According to CN's RTC Manual, item 726, when time permits, there is an expectation that RTCs will advise train crews of upcoming train meets or any other situation where a train would be delayed, stopped, or waiting. These instructions were in place to assist in fuel conservation and train handling. On 27 October 2007 an RTC notice was issued indicating that RTC's were to refrain from providing such information to train crews, unless a crossing was at such a location, to avoid crew anticipation of a specified meet location, in case the location was to change. It was indicated by the railway that it was preferable not to provide the most up to date available information so that crews would be required to remain fully cognizant of their surroundings and ready to react appropriately to any condition.

On the day of the accident, Train 417's crew was not advised of the upcoming meet at Peers.

Situational awareness and crew resource management

The conductor did not question the locomotive engineer's operation of Train 417 on the main track at Peers, even though he recognized that the next signal ahead would be a stop signal. He believed that the engineer must have been apprised of something that he was not, for example that Train 342 would clear the main track before Train 417 arrived and a permissive signal would be lined for Train 417 at the west end of the track.

When making and implementing plans to move and control a train, the success of a crew's decisions and actions greatly depends upon their assessment and understanding of train operations and an ability to select appropriate courses of action based on situational awareness. Under general operating conditions, situational awareness develops on three different levels.Footnote 11 Initially, a person perceives situational elements from information displays, communications, or other references. This information is integrated into an overall understanding of the situation by the application of past experience and knowledge of how the system works, often referred to as a mental model. Finally, the person projects this acquired information into the future to make and modify plans as tasks are completed or delayed.

Cues, or information about the situation, can vary between clear and ambiguous. The clearer the cues, the lesser the effort needed to interpret them and thus the more accurate the diagnosis of the situation will be. Once a mental model is adopted, it is very resistant to change. In order to change one's thinking, the existing model must be superseded by another, with new information being sufficiently compelling to result in an update of the mental model.

A train crew's situational awareness may come from various information sources. These can include radio transmissions, such as crew-to-crew conversations, or the message received from a wayside inspection system. Other information sources can be made up of signal aspects and RTC information, in-cab information displays, a crew's view of the track from the cab, landmarks (for example, sidings marked at the halfway point), environmental conditions, sounds from the environment including noise from other trains and traffic, and written information such as timetables and operating bulletins. Railway rules and operating instructions affecting situational awareness, such as those in the CROR and General Operating Instructions, provide information that operating crews are either permitted or required to use.

Crew resource management (CRM) programs encourage the respectful questioning of authority; the primary goal being enhanced situational awareness. Appropriate communication techniques are required to be taught at all organizational levels so that supervisors understand that the questioning of authority is not a threat and subordinates learn the correct way to question the person of authority.Footnote 12

The Board has previously identified a lack of information available to train crews for developing adequate situational awareness (TSB report No. R96Q0050). The TSB expressed concerns that there were no established CRM programs in use on railways that would ensure that all persons involved are aware of the most up-to-date and accurate information concerning the movement of trains and engines. The report also expressed concerns that, when specific methods of communications transmission and verification are not in place, there is a greater risk that a piece of information could be misinterpreted.

Additionally, in report number R98V0148, the Board determined that the current emphasis by airlines and aviation regulatory agencies on CRM training has created a substantial improvement in cockpit discipline and performance. The "trans-cockpit authority gradient" should be relatively flat as a result of CRM development. The marine industry has adopted bridge resource management training for ships' officers and a similar safety improvement in accidents or incidents attributed to communication irregularities was anticipated.

It was suggested that within the railway industry, crew pairing commonly comprised senior and junior crew members and, therefore, the importance of CRM training within the railway industry should be developed as a safety initiative to eliminate the "authority gradient" factor. Both CPR and VIA adopted this approach and have recurrent training in situational awareness and communications between crew members.

As of 2004, the British Columbia Institute of Technology offers a CRM course that is part of the curriculum offered in the railway conductor's course. It aims to educate individuals with no railway experience. The material is provided by the Railway Association of Canada and promotes greater awareness of safety, thus contributing to the prevention of incidents and accidents.

Analysis

In this occurrence, there were no mechanical problems with the trains, and no track or signal problems that contributed to the incident. The analysis will focus on train handling issues related specifically to operational risks in Centralized Traffic Control, fatigue, and training. In addition, the analysis will consider the effects of crew members remaining on duty after a traumatic event and the importance of advance information about train meets.

The accident

The collision occurred when Train 417 passed a stop signal at the west end of Peers and struck the side of Train 342 as it was entering the siding. Train 417's locomotives and a number of cars on both trains derailed. Train 417's fatigued locomotive engineer lost situational awareness as he approached Peers. He had formed a mental model that he was actually at another location, Yates, about 13 miles away, where there were also two tracks. Although he acknowledged the signal indication at the east end of Peers and he was aware of the requirement to stop at the next signal, these stimuli were not sufficiently compelling to correct his mental model and bring about the appropriate train control decisions.

The conductor was not qualified as a conductor locomotive operator and, therefore, was inexperienced in train-handling techniques, including stopping requirements. As such, he deferred to the locomotive engineer's experience and did not question his actions.

It was not until the stop signal at the west end of Peers was visible and recognition that Train 342 was still foul of the main track that Train 417's crew became fully cognizant of the imminent danger.

When an authority gradient exists between junior and senior employees, there is a danger that safety-compromising behaviour can be overlooked because less experienced employees are reluctant to question their senior. Even though the railway company operated under rules and instructions that placed responsibility for safe operation on all crew members, the authority gradient prevailed and the conductor did not intervene to stop the train. In the absence of procedures that recognize the risks inherent in an authority gradient, intra-cab communication can fail. Strategies to encourage open lines of communication among crew members, such as well developed CRM practices, are one way to address this problem. In the absence of procedures that recognize the risks inherent in an authority gradient, intra-cab communication can fail.

Positive train control

There were a number of safety defences in place on the Edson Subdivision that were designed to prevent an accident of this type from happening. Some were associated with the train control system and some were associated with the Canadian Rail Operating Rules (CROR) and General Operating Instructions. All can be categorized as administrative in nature. For example, wayside signals include a physical signal installation combined with an administrative requirement to follow the signal indication. This defence relies upon the crew to observe the signal and take the appropriate actions. If the crew does not take the appropriate action the defence as a whole has failed. The CROR makes all crew members responsible for following the rules. This defence provides an administrative requirement to follow the rules but provides no additional assurance of safety if, for whatever reason, a crew does not comply. These defences, although usually effective, have little or no backup defence.

Although no major Canadian railway has implemented Positive Train Control (PTC), that system does offer additional defences. If a crew does not respond appropriately to a signal or other restriction, PTC has the ability to alert the crew to the fact that they are not reacting as expected and, as a last resort, the system can intervene to slow or stop the train by applying the brakes. Intervention from a system such as PTC would have compensated for the crew's lack of situational awareness and prevented the collision.

Work/rest rules and fatigue

Research has consistently shown that long periods of wakefulness result in fatigueFootnote 13 and this can occur even if short naps are taken during periods of wakefulness of twenty hours or more. Considering that Train 417's locomotive engineer had been awake for about 22 hours without any restorative rest and the conductor had been awake for approximately 21.5 hours with only an approximate one-hour nap, it is very likely that the performance of the crew had diminished.

The results of the fatigue analysis indicate that Train 417's crew was insufficiently rested to be engaged in safety-critical tasks. While the railway's General Fatigue Management Plan for Rail Operating Employees lists a number of suggested strategies to deal with fatigue, opportunities to enact several of these countermeasures were not taken.

While the plan attempts to educate employees on the effects of fatigue, it was never implemented on CN system-wide and a limited number of employees received the training. While some information bulletins were issued on the topic, none were issued since 1990.

Additionally, while fatigue management is a shared responsibility between the railway company and its employees, it is extremely difficult for employees to take appropriate measures in obtaining adequate rest at times when it is not possible to reliably anticipate the call for work.

For example, between October 12 and 24, the locomotive engineer worked seven shifts on Train 417, predominantly ordered during daylight hours (1215 – 1515), worked an average of eight hours per shift, and was typically off duty before midnight.

Based on this routine, he likely assumed that he would not be ordered on the occurrence train in the late afternoon and therefore would not have expected a nap would be required. In addition to Train 417, he worked another eight shifts on various other assignments. As such, this work pattern resulted in irregularly scheduled work every day for 15 days. This work pattern resulted in an inconsistent sleep/wake routine, disrupted circadian rhythms, and contributed to his level of fatigue.

Recent changes to the railway's management practices (prohibiting booking unfit) have made it more difficult for crews to remove themselves from potentially unsafe situations in circumstances where they find themselves subject to duty but not sufficiently rested. The potential exists that a crew member can come to work feeling un-rested and the first acceptable opportunity to take rest is ten hours after being on duty. Without a system to assess a crew member's level of fatigue, it is likely that from time to time fatigued train crews will feel compelled to report for work without adequate rest, creating the risk of an accident.

Canadian railways participated in CANALERT ‘95 and learned a great deal about the effects of fatigue on their employees and the effectiveness of various countermeasures. However, countermeasures in place were ineffective and a fatigued crew on Train 417 operated into the side of Train 342.

Training

Operational changes, such as two man train crews, locomotive control system switching operations, and attrition of older employees have changed how conductors are trained. To meet these changing needs, the railways have developed fast track conductor training programs. At times, operational needs have led to the railways making use of trainees in train service. While this solution may meet operational needs, there have been a number of recent accidents where employees were not fully acquainted with their duties nor familiar with the territory where they operated. In this accident, the conductor had been part of a fast-tracked process at the completion of which he was placed in active service. Consequently, when the necessary steps to slow the train were not taken, the conductor did not intervene because he was insufficiently experienced or trained to have recognized the danger and to communicate that concern to the locomotive engineer.

Remaining on duty after a traumatic event

Train 417's crew had been subjected to a stressful event. Unaware of the severity of the collision, the Rail Traffic Control Centre (RTCC) treated them in a business-as-usual manner. After confirming with the crew that there were no physical injuries, the RTCC instructed them to perform additional safety-critical tasks. The crew did not request relief under CN's Critical Incident Response program, nor did anyone remind them of such a right.

In the event of an accident, rail traffic controllers and railway managers are often faced with making immediate determinations of a crew's level of fitness. This is most often accomplished through radio communication and involves reliance on the self-assessment of the crew involved. RTCs and railway managers are not formally trained to make this type of determination. Furthermore, an individual's post-accident self-assessment is frequently unreliable. RTCs and managers should be aware of the potential for post-incident stress. Another crew was available at that location (during favourable weather, approximately two‑thirds of a mile away from Train 417's head end). These resources could have been tasked instead of relying on Train 417's crew for a damage assessment.

Advance information about train meets

The railway notice requiring that RTCs refrain from advising train crews of upcoming meets was issued to promote crew reliance on the signal system and to avoid speculation, should the original meet change. This approach is contrary to sound information flow practices in safety sensitive environments. Generally speaking, individuals who are provided the most up-to-date and relevant information are better equipped to make decisions than those who are not. In this specific instance, had Train 417's crew been advised of the upcoming meet, the likelihood of collision would probably have been reduced.

Findings

Findings as to causes and contributing factors

- After passing a "clear to stop signal" at the east end of Peers, Train 417 did not slow down significantly.

- The collision occurred when Train 417, while under emergency braking, passed a stop signal at the west end of Peers and struck the side of Train 342 as it was entering the siding.

- Train 417's locomotive engineer lost situational awareness as he approached Peers.

- The conductor deferred to the locomotive engineer's experience and did not challenge his actions.

- Train 417's crew was insufficiently rested to be engaged in safety-critical tasks.

Findings as to risk

- From time to time, fatigued train crews will feel compelled to report for work without adequate rest, creating the risk of an accident.

- In the absence of procedures that recognize the risks inherent in an authority gradient, intra-cab communication can fail.

- Had Train 417's crew been advised of the upcoming meet, the likelihood of collision would probably have been reduced.

Other findings

- Intervention from a system such as Positive Train Control may have compensated for the locomotive engineer's loss of situational awareness and prevented the collision.

- Despite previously-acquired knowledge on fatigue, the countermeasures the railway had in place were ineffective.

- In view of the severity of the accident and the availability of other crews at that location, consideration should have been given to relieving Train 417's crew as soon as possible.

Safety action taken

On 20 March, 2007, the TSB sent Rail Safety Advisory (RSA) Letter 13/07 (arising from this investigation) that raised concerns about operating trains without restorative rest. The letter suggested that Transport Canada might review the adequacy of current work/rest rules and the extent to which railway employees are empowered to assess their own level of fatigue.

On 21 December 2007, TSB sent a RSA Letter 15/07 (arising from this investigation) that raised concerns regarding the potential consequences of remaining on duty after a traumatic event. The letter suggested that Transport Canada might want to review the manner in which railways manage their involved employees subsequent to a traumatic event.

In response to RSA 13/07 and RSA 15/07, no safety actions were taken.

Canadian National (CN) advised that it intends to review the crew resource management (CRM) content of Canadian Pacific Railway, VIA Rail Canada Inc., and the British Columbia Institute of Technology training programs to determine if additional content would be of value in CN's training courses.

In addition, CN will be adding additional focus to the training for both junior and senior employees identifying how an authority gradient may affect communications between train crew members and providing information on how to mitigate this.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .

Appendices

Appendix A

According to the Sleep, Activity, Fatigue, and Task Effectiveness (SAFTE) model,Footnote 14 the factors that are likely to increase fatigue levels and subsequent errors and that are listed in the Fatigue Avoidance Scheduling Tool (FAST) output table are:

- less than eight hours of sleep during the previous 24 hours-labelled Sleep (last 24 hours);

- greater than eight cumulative hours of missed sleep-labelled Chronic Sleep Debt;

- greater than 17 hours of continuous wakefulness-labelled Hours Awake;

- working during the low performance period-labelled Time of Day; and

- difference between the normal work/rest cycle and the actual cycle-labelled Out of Phase.

The performance metrics predicted by SAFTE and listed in the output table in FAST are:

- performance on psychomotor vigilance tasks (PVT); this is a measurement of ability to maintain a focus of attention in order to perceive and react to stimuli-labelled Effectiveness and graphed as a curvilinear function;

- average speed of mental operations as a percentage of performance by a normally rested person, also known as the average cognitive throughput on standard cognitive tests-labelled Mean Cognitive;

- likelihood of a lapse in attention relative to a normally rested person that may be due to state instability and the sudden uncontrollable onset of a brief period of sleep-labelled Lapse Index;

- average reaction time expressed as a percentage of the average reaction time of a normally rested person-labelled Reaction Time; and

- amount of useable sleep that remains, based on the concept that sleep is used up by wakefulness-labelled as Reservoir in the output table.

The following two tables indicate the influence of work and sleep schedules on performance effectiveness. The horizontal axis represents work and sleep; the vertical axis represents performance effectiveness.