Non-main-track derailment

Canadian Pacific Railway

Freight train 293-16

Mile 0.40, Red Deer Subdivision

Alyth Yard

Calgary, Alberta

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 18 February 2016, at approximately 0623 Mountain Standard Time, Canadian Pacific Railway freight train 293-16, proceeding north toward the Red Deer Subdivision at approximately 2.5 mph, derailed 13 cars (11th to 23rd) on the east leg of the north wye in Alyth Yard, Calgary, Alberta. There were no injuries and no dangerous goods were released.

Le présent rapport est également disponible en français.

Factual information

The accident

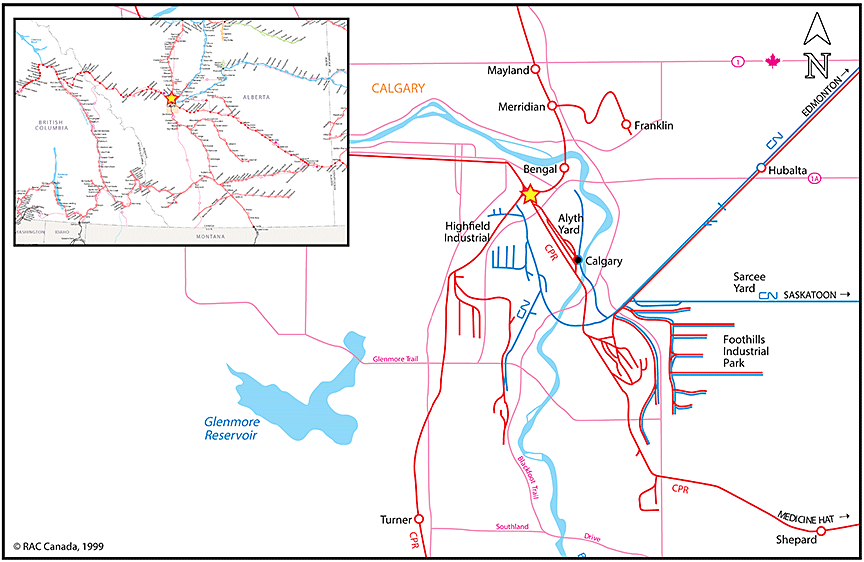

On 18 February 2016, at approximately 0546,Footnote 1 Canadian Pacific Railway (CP) freight train 293-16 (the train) arrived at Alyth Yard, Calgary, Alberta (Figure 1), from Medicine Hat, Alberta. The crew had been instructed to set off the head-end 39 cars into track N11.

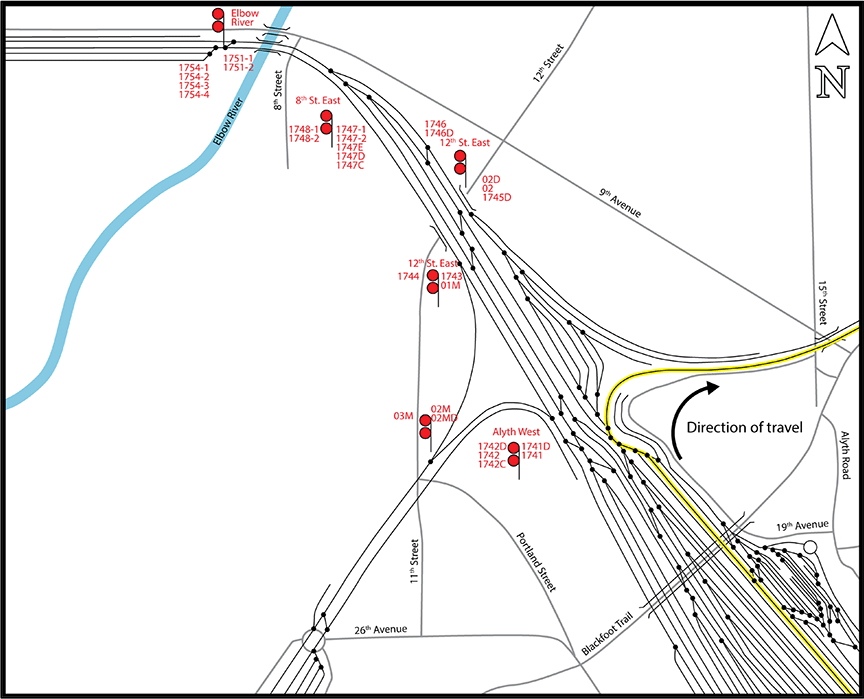

The train proceeded through track N14 and through the east leg of the north wyeFootnote 2 (Figure 2) toward Bengal on the Red Deer Subdivision to facilitate the set-off.

When the conductor requested that the locomotive engineer (LE) advance 5 more car lengths, the LE initiated a throttle increase before observing the required riseFootnote 3 in brake pipe pressure (BPP) following a brake release. The throttle was increased to position 6. At approximately 2.5 mph, 13 cars (the 11th to 23rd) derailed to the inside of the curve. As the train came apart, the brakes activated in emergency and the train stopped.

Recorded information

Data from the locomotive event recorder on the lead locomotive (CEFX 1057) was reviewed, and the following information was determined:

- On arrival at the east end of Alyth Yard, the train slowed to 1.4 mph to allow the conductor to line a switch for the train to enter track N14.

- After lining the switch, the conductor boarded the locomotive. The train then picked up speed and was travelling through track N14 at 6.7 mph.

- Nearing the west end of track N14, a minimum reduction train brake application (7 pounds per square inch [psi]) was made to slow the train down. The conductor exited the locomotive in order to help the LE guide the train to a stop by radio from the ground.

- The throttle was advanced from position 3 to position 6 to keep the train from stalling. The train then continued around the east leg of the wye toward Bengal.

- While the train was travelling at approximately 2.5 mph, the brakes were released. As the release was propagating toward the rear, at approximately 0623, a train‑initiated emergency brake application occurred.

- The lead locomotive reached a maximum tractive effort of 135 000 pounds when the cars derailed. At this point, the brakes at the rear of the train had not started to release.

Site examination

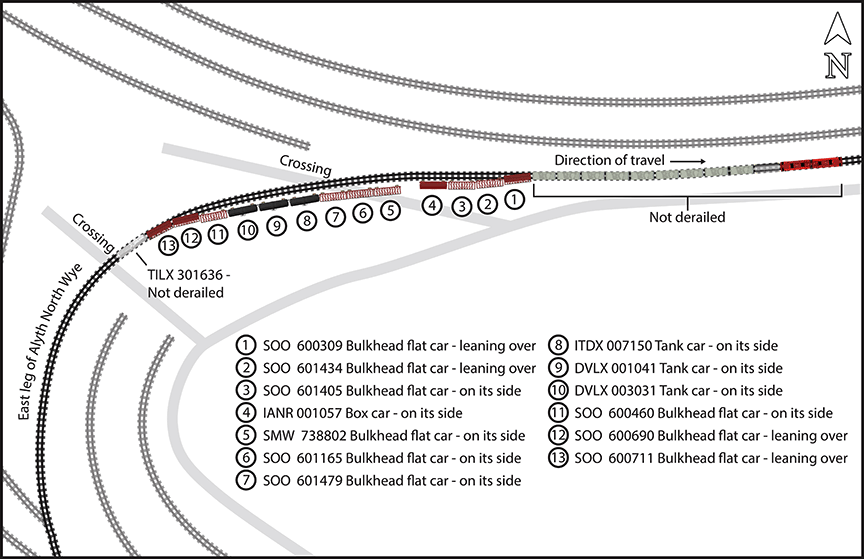

The derailment spanned approximately 1050 feet, and 9 of the 13 derailed cars were pulled over onto their sides. The track sustained minimal damage, consisting of wheel flange marks on the top of the south rail (Figure 3).

A power pole and line were knocked over at the location of the 6th derailed car; the power utility company responded in order to de‑energize the line.

Immediately preceding the 13 derailed cars were 10 cars (9 empties and 1 load) as well as the 2 locomotives (Figure 4). Of the 13 derailed cars, 9 were empty centre beam bulkhead flat cars, 1 was a loaded box car containing canned green beans, and 3 were empty (residue) tank cars that had last contained molten sulfur. The first 2 derailed cars were upright and leaning over. The next 9 cars were on their sides, and the last 2 derailed cars were upright and leaning over.

The train had separated between the 4th and 5th derailed cars. The remainder of the train was not derailed. Following the derailment, a cut was made one car behind the last derailed car, and the tail end of the train was pulled back into Alyth Yard.

Alyth Yard and the east leg north wye

Alyth Yard is situated in the neighbourhood of Inglewood in an urban and industrial area of Calgary, Alberta. The yard is located on the west end of the Brooks Subdivision. It connects to the Brooks Subdivision to the east, the Laggan Subdivision to the west, the Aldersyde Subdivision to the south, and the Red Deer Subdivision to the north. The junctions for the Aldersyde and Red Deer subdivisions are located on the west end of Alyth Yard.

Alyth Yard is non-main-track territory and Canadian Rail Operating Rules pertaining to movements on non-main track apply. The east leg of the north wye is on the northeast side of Alyth Yard and connects to the Red Deer Subdivision at Mile 1.2. The east leg of the north wye is in a 12-degree curve.

The track in the area was 136-pound Nippon steel, manufactured in 2007, and 16‑inch rolled tie plates with elastic fasteners secured to the hardwood ties by lag screws. All components were in good condition.

On 16 February 2016, CP had operated a track evaluation carFootnote 4 on the Red Deer Subdivision between Mile 0.0 and Mile 1.29. There were no defects noted in the vicinity of the point of derailment. Two urgent defects were identified near Mile 0.1 and addressed on the same day.

Train Area Marshalling Area 2

CP uses an in-house train marshalling program called Train Area Marshalling (TrAM) to establish the distribution of tonnage and power on its trains so that in-train forces can be safely managed. The physical and operating characteristics of the railway's territories (subdivisions) were evaluated, and 6 different train marshalling areas were established, Area 1 being the least restrictive and Area 6 being the most restrictive. The railway territory for this occurrence contained 5 of these 6 marshalling areas.

CP issued a summary bulletin for the Prairie Division (Alberta) on 14 October 2015 with the following terminal instructions for the Calgary Terminal:

EAST LEG OF NORTH WYE - ALYTH TERMINAL

The east leg of North Wye, Alyth is designated TrAM area 2. Trains meeting TrAM area 2 requirements may operate on the east leg of the North Wye with the following restrictions:

- Locomotive Engineers are restricted to throttle 3 to limit undesirable tractive effort through the wye.

- Following a release of the automatic brake, if a further reduction is required, the throttle must not be advanced or dynamic brakeFootnote 5 adjusted until the SBU [sense and braking unit]Footnote 6 is observed showing a minimum of 3 psi rise. This may require or result in stopping the train to allow for the brakes to release.Footnote 7

Until 19 November 2012, the Red Deer Subdivision had been designated TrAM Area 1, except the east leg of the north wye at 12th Street, which was designated TrAM Area 6 for southbound trains. For operational reasons, CP changed the track configuration at this location, re-evaluated the TrAM requirements, and introduced TrAM Area 2 for trains travelling in either direction on the east leg of the north wye only. The rest of the Red Deer Subdivision remained TrAM Area 1.

The LE on the occurrence train was aware that the east leg of the north wye was designated TrAM Area 2, but he did not specifically recall this information on the day of the occurrence. There were no memory aids, such as signs, at Alyth Yard; railways generally limit the number of signs in yards to avoid creating unnecessary obstructions.

Train and equipment information

The train was made up of 2 head-end locomotives, 29 loaded cars and 103 empty cars. It was 8794 feet long and weighed 7340 tons. The 29 loaded cars were marshalled throughout the train at 7 locations in groups of 1 to 15 cars. The 103 empty cars were marshalled throughout the train at 8 locations in groups of 1 to 61 cars.

The train's 2 locomotives were GE AC4400Footnote 8 6-axle units. The locomotives were in serviceable condition. Maintenance records for the locomotives indicated that there were no outstanding issues.

Before the derailment, no defects had been reported for the rail cars involved. All cars had received a certified car inspection and a No. 1 air brake test within the previous 30 days at various locations. The train had proceeded over the hot box detector at Mile 163.1 with no alarms.

The train met TrAM Area 2 requirements.

Lateral and vertical forces at the wheel rail interface

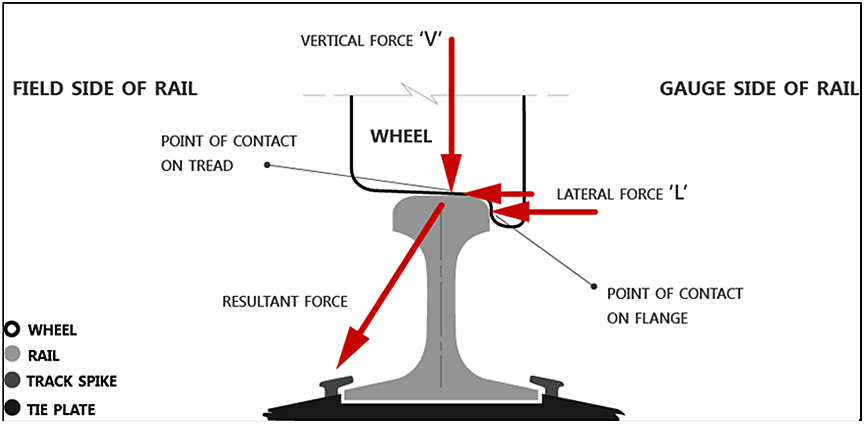

A combination of lateral (L) and vertical (V) forces exists at the wheel-rail interface (Figure 5). The ratio of lateral-to-vertical (L/V) force indicates the likelihood of a derailment. When a high lateral force and low vertical force are present (e.g., as with an empty car), the high lateral force will tend to push the wheel flange up and over the gauge face of the rail, resulting in a wheel-climb derailment.

When a train is being pulled through a curve, the locomotives tend to stretch or "string-line" the train, which pulls the wheel flanges against the inside rail of the curve. This lateral force at the rail varies directly with the locomotive tractive effort, track grade, and degree of curvature. If the draft force generated by the locomotives is excessive or if there is a significant run-out of train slack, the L/V force can reach critical levels where car wheels climb or overturn the inside rail. Empty long centre beam bulkhead flat cars are particularly susceptible to these forces.

According to CP's Train Accident Cause Finding Manual, string-lining derailments "are caused by heavy draft loading, including steady-state draft loading or (more often) dynamic run‑outs of slack."Footnote 9 String-lining derailments exhibit the following characteristics:

- Stringlining derailments happen in curves, not in tangent track.

- Stringlining is often associated with excessive application of power in forward movements, and often involves the head-end cars of a train derailing after the train accelerates from a low speed in high curvature territory (CLASSIC SCENARIO).

- Derailed cars are generally empty, lightly loaded, long overhang or long car/short car combinations.

- Derailed cars are pulled over the low rail, usually found in a straight line—but sometimes the low rail overturns and high wheel drops in.

- Short flange mark on top of low rail, or on web/lower fillet, depending if the wheel climbed or the rail rolled over.Footnote 10

Weather

At the time of the occurrence, the weather was −1°C, mostly cloudy, with visibility of 24 km.

Work instructions for area of occurrence

Operating employees are expected to know, understand, and comply with the Canadian Rail Operating Rules, general operating instructions, special instructions, bulletins, and local instructions that apply to the territory on which they are operating. If in doubt, employees are expected to refer to reference material or seek additional guidance before proceeding.

There is no requirement to review work documents when entering the yard, and LEs do not typically have manuals or instructions for the yard open while they are operating trains.

Crew information

The crew consisted of a conductor with 6 years of service and an LE with 29 years of service. Both crew members were qualified for their respective positions and familiar with Alyth Yard and the vicinity. The LE had been routed around the east leg of the north wye while yarding a train several months before the occurrence. However, his experience had been that the preferred routing when setting off cars at this end of the yard was straight on yard track 8.

The crew had been ordered for an on-duty time of 2220Footnote 11 on 17 February 2016 in Medicine Hat, Alberta. The train departed Medicine Hat at 0025 on 18 February 2016 and arrived in Calgary at 0546 the same day.

Work/rest history of locomotive engineer

At CP, work hours for LEs in pool service are not scheduled in advance. Work assignments are determined by an LE's position on a list of available employees and by the availability of trains. An LE will typically receive 2 hours' notice of the requirement to report for duty.

In this occurrence, the derailment took place at approximately 0623 while the crew was performing switching operations in Alyth Yard toward the end of the shift. The crew had reported for duty at 2205 the previous evening in Medicine Hat and had been on duty for approximately 8 hours at the time of the occurrence.

The LE went to bed at approximately midnight on 17 February 2016 and woke up at approximately 0700 that morning. However, the LE had not been sleeping well during the 2‑week period prior to the occurrence, frequently waking and experiencing difficulty falling back asleep. He had been occupied throughout the day on 17 February 2016, attending to personal commitments. The LE had been anticipating a call to go to work in the afternoon.Footnote 12 However, when he consulted the train line-up later in the day, he learned that his call would likely not come until much later than originally anticipated. By the time the call came, at about 2020, the LE had not taken the opportunity to sleep.

CP permits employees to book unfit when not sufficiently rested, provided they do so prior to receiving their call. In this case, the LE did not book unfit.

At the time he accepted the call, the LE did not feel fit to report for work. However, he feared discipline if he refused duty, given that he had previously been disciplined, in the form of a temporary suspension, for pattern absenteeism. As a result, the LE accepted the call and had therefore been awake for over 23 hours at the time of the occurrence.

The LE's work and rest history is included in Appendix A. Following 5 days of bereavement leave and 1 day off at the beginning of February, the LE had worked 3 overnight trips, 1 evening trip and 3 daytime trips in the 9 days preceding the occurrence. There was little pattern to the LE's work hours. The LE typically booked 6 to 8 hours' rest at the away terminal and just under 24 hours' rest on arrival at the home terminal. When booking rest, an employee is unavailable for recall, which provides an opportunity for uninterrupted rest.

At CP, new hires receive formal fatigue management training as part of their conductor training. The LE had not received this training because he had completed conductor training prior to the introduction of fatigue management training.Footnote 13 However, all operating employees have access to educational materials covering fatigue management topics, including sleep hygiene; body clock; sleep disorders; sleep and performance; diet, health, and lifestyle; definitions of fatigue and alertness; stress management; various sleep schedules; countermeasures; and individual and age differences.

Work/rest rules for operating employees

The Work/Rest Rules for Railway Operating EmployeesFootnote 14 (the Work/Rest Rules) are based on the principle of shared responsibility for fatigue management. Specifically, Section 2 of the Work/Rest Rules establishes that companies must take a flexible approach to managing fatigue. Companies are responsible for establishing and maintaining working conditions that allow operating employees to obtain sufficient rest between tours of duty and to maintain alertness throughout duty periods. Employees have a responsibility to use the rest opportunity so they can report for work rested and fit for duty. The Work/Rest Rules define "fit for duty" as "reporting for duty rested and prepared to maintain alertness for the duration of the tour of duty."

In keeping with the need for a flexible approach to managing fatigue, section 6 of the Work/Rest Rules requires railway companies to implement a fatigue management plan. At a minimum, the plan must consider education and training, scheduling practices, dealing with emergencies, alertness strategies, rest environments, implementation policies as well as evaluation of fatigue management plans and crew management effectiveness.

Section 7 of the Work/Rest Rules requires that the company file its fatigue management plan with Transport Canada.

Provisions for booking unfit

Current collective agreements between the railway and the bargaining agents representing LEs and conductors contain various provisions for these employees to book rest and obtain sleep (Appendix B). If crew members are unable to obtain sufficient sleep and are not fit due to fatigue, the ability to remove themselves from work is also set out in collective agreement provisions. The collective agreement between CP and LEs states that "[a]n Engineer being physically unfit for duty will report same to the Crew Management Centre, so that the employee may not be called."Footnote 15

In addition, the following sentence was added to this provision through arbitration that occurred in December 2012 pursuant to the 2012 Restoring Rail Service Act: "The employee will not be disciplined for 'booking unfit'."Footnote 16

Employees could be requested to provide an explanation to their supervisor if they are unable to report fit and rested. The "booking unfit" provision is typically used in circumstances where the employee has been unable to obtain sufficient rest. Other leave provisions are used if the employee is unable to work due to illness or personal issues.

In 2016, 1382 employees at CP booked unfit a total of 2847 times. From January to August 2016, according to an attendance investigation where one of the absence types included booking unfit, 99% of employees who booked unfit were not disciplined.

Previous attendance-related discipline for locomotive engineer

CP has implemented availability standards and an attendance policy to monitor and address employee attendance levels. The standards are used to measure what is considered acceptable attendance for Train and Engine employees. Unwarranted absences can result in an investigation and are handled in accordance with the attendance policy.

The LE involved in this occurrence had previously been disciplined for various attendance issues, including the following:

- 6 missed callsFootnote 17 between 2009 and 2013. Two of these were recorded for information, 2 resulted in the LE being cautioned, and 2 resulted in the LE being assessed demerits.

- 2 instances of the LE being disciplined for "booking sick when called"Footnote 18 (in 2009 and in 2012). In both cases, the LE was assessed demerits.

- 5 instances of the LE being disciplined for "pattern absenteeism" between 2009 and 2015. One instance was recorded for information, 2 resulted in the LE being cautioned, 1 resulted in the LE being assessed demerits, and 1 (the most recent occasion, in January 2015) resulted in the LE being assessed a 5-day suspension.

Canadian Pacific Railway fatigue management plan

Requirements for establishing fatigue management plans are set out in the Work/Rest Rules. Pursuant to these requirements, CP and the Teamsters Canada Rail Conference (Teamsters) have established a fatigue management plan (FMP) that addresses education and training, scheduling practices, dealing with emergencies, alertness strategies, rest environments, implementation policies, and evaluation of FMPs and crew management effectiveness.Footnote 19

The plan is based on the principle of shared responsibility for fatigue management and indicates that solutions will be achieved through a "combination of corporate and individual responsibility and empowerment to manage fatigue."Footnote 20 The FMP elaborates on this principle, setting out roles and responsibilities across the system. The FMP outlines the role of operating employees: "To manage their rest within the time frames provided by the Work/Rest Rules in a way that will enable them to report for duty in a rested condition."Footnote 21 Among the roles specified for CP Field Operations, the FMP includes the following:

Footnote 22CP's FMP acknowledges that "[t]he long-term success of the FMP depends upon ongoing measurement and review."Footnote 23 Accidents and incidents provide an important opportunity to evaluate the effectiveness of fatigue management. To that end, the FMP commits to examining fatigue following accidents and incidents and to review local procedures where fatigue is found to have played a role. Specifically, the FMP states the following:

Footnote 24The FMP does not set out a method of examining fatigue after an accident or incident.

With respect to fatigue management training, the FMP commits to providing fatigue management training to all new operating employees during the conductor training program.Footnote 25

Canadian Pacific Railway investigation

CP conducted an internal investigation of this occurrence. CP determined that the cause of the incident was improper use of locomotive throttle, which was contrary to the restrictions on throttle use set out in the Prairie Division (Alberta) summary bulletin terminal instructions for the Calgary Terminal.

CP's post-incident investigation synopsis stated that the LE acknowledged the following to the company: "He was fit and well rested when he accepted the call for train 293-16. He forgot about the above operating restriction and was remorseful for being responsible for this incident."

CP's internal investigation did not include a review of the LE's sleep history and did not identify any systemic issues that may have contributed to the LE forgetting about the operating restrictions.

Factors affecting working memory and the ability to maintain situational awareness

Effective performance in operational environments requires operators to continually update a mental model of their current situation. Maintaining situational awareness is a 3‑stage process where operators take in information from their environment, understand its significance within the current situation, and project into the future to assist in planning.Footnote 26

The ability to recall information and retain it in working memory represents a significant bottleneck for an individual's situational awareness.Footnote 27 Further, the limitations of working memory can become more acute when individuals are faced with normal operational stressors, including fatigue:

premature closure Footnote 28A number of measures have been shown to improve operators' ability to maintain situational awareness: specifically, operator training that provides techniques and skills to maintain situational awareness, and system design that focuses on providing operational data in a useable form at the appropriate time (e.g., checklists or signs).Footnote 29

Performance effects of fatigue

Sleep is a biological need. Fatigue resulting from insufficient sleep impairs many aspects of human function critical to safe operations, including judgment, cognitive performance, memory, vigilance, and the ability to focus attention. Further, research has demonstrated that individuals are not good judges of their level of performance impairment from chronic sleep loss. The performance effects of fatigue gradually increase with the amount of time an individual has been awake and will be more pronounced in individuals who are experiencing acute or chronic sleep disruptions.Footnote 30 Even in a well-rested individual, performance-impairing effects of fatigue can be expected after approximately 16 hours of sustained wakefulness, with effects intensifying as time awake increases.Footnote 31 In addition to the

performance effects, fatigue has been shown to have motivational effects affecting the manner in which individuals approach their tasks:

Footnote 32TSB Watchlist

The TSB Watchlist identifies the key safety issues that need to be addressed to make Canada's transportation system even safer.

Fatigue management systems for train crews will remain on the TSB Watchlist until

- Transport Canada completes its review of railway fatigue management systems; and

- Transport Canada and the railways implement further actions to effectively mitigate the risk of fatigue for operating crew members on freight trains.

Fatigue management systems for train crews are a Watchlist 2016 issue. As this occurrence demonstrates, fatigue continues to pose a risk to the safe operation of trains, particularly freight trains, which move 70% of the country's surface goods. The initiatives taken to date have been inadequate to fully address the issue.

Analysis

The track and equipment were maintained in good condition and there were no defects observed that were considered contributory to the occurrence. The analysis will focus on train operations, timely review of operational information, fatigue management, and internal incident investigation with regard to fatigue.

The accident

The occurrence crew members were performing switching operations in Alyth Yard just after 0600 on 18 February 2016, having operated overnight from Medicine Hat. The accident occurred when several wheels came off the rail while the train was operating through a 12‑degree curve.

When a train is being pulled through a curve, the locomotives tend to stretch or "string‑line" the train, which pulls the wheel flanges against the inside rail of the curve. This lateral force at the rail varies directly with the locomotive applied effort, track grade, and degree of curvature. The lateral-to-vertical forces at the wheel rail interface reached a critical level where the car wheels climbed the inside rail. As a result, the train string-lined in the curve and derailed.

When the conductor requested that the locomotive engineer (LE) advance 5 more car lengths, the LE initiated a throttle increase before observing the required rise in brake pipe pressure following a brake release. The tractive effort of the locomotives reached 135 000 pounds when the throttle was increased to position 6, which was above the maximum throttle position for that train in this area. At this point, the train brakes at the rear of the train had not started to release.

Timely reminders of train-handling requirements

Best practices for handling a long, heavy train around a curve dictate that throttle be used conservatively, and only after ensuring that the brakes have adequately released through the length of the train. These principles were reflected in the Canadian Pacific Railway (CP) train‑handling guidelines for the Calgary Terminal. Specifically, when operating around the wye, the occurrence train was limited to throttle position 3, and the throttle was to be advanced only after a rise in brake pipe pressure was observed following the release of the brakes. Given that train crews are required to read these guidelines, the LE was expected to be aware of these restrictions, even though it had been several months since he had been routed around the east leg of the north wye.

Special train-handling instructions exist for long, heavy trains operating on the wye where the occurrence took place, as well as through the curve of this wye. Specific train-handling requirements relating to the use of the locomotive throttle for the occurrence location were not followed. Although the train crew members had a copy of the related bulletin, they did not review it prior to the train's arrival in Calgary.

A significant bottleneck in an operator's ability to maintain situational awareness is the retention of relevant information in working memory—an ability that decreases if the information is not reviewed in a timely manner. In addition, when operators are exposed to normal operational stressors such as time pressure and fatigue, it may be difficult to retain relevant information in working memory.

These limitations can be overcome through training and procedures that require information relevant to the current operational environment to be reviewed and briefed prior to an operation. In this occurrence, there was no requirement for the operating crew to review the relevant materials prior to initiating a train movement, and there was nothing in the operating environment, such as a sign, to remind crews of the change to operating requirements at that location. It was generally expected that operating employees would exercise judgment and refer to materials in case of uncertainty.

If train crews do not review the relevant information relating to train operations in a given location prior to performing tasks at that location and if there is no other trigger to recall critical operational information, there is an increased risk of inappropriate train handling.

Fatigue management

CP's fatigue management plan (FMP) indicates that, in order to effectively manage fatigue, the company will monitor the accuracy of train line-ups and take action to ensure employees have the information to enable them to effectively manage sleep and fatigue.

Even in a well-rested individual, performance-impairing effects of fatigue can be expected after approximately 16 hours of sustained wakefulness, with effects intensifying as time awake increases.Footnote 33 In this occurrence, the LE had been awake for more than 23 hours at the time of the accident. In addition, the accident occurred toward the end of a period of circadian low. At the end of the previous sleep period the day before the accident, the LE had not been sleeping well due to personal and family issues. The LE was likely fatigued due to poor-quality sleep in the 2 weeks prior to the occurrence and being awake for at least 23 hours at the time of the accident.

Fatigue has been shown to have an impact on the manner in which individuals approach tasks: fatigued individuals take greater risks and perform tasks more quickly, which results in an increased incidence of error.Footnote 34 In addition to the fact that the train‑handling guidelines were not reviewed, the LE's working memory and vigilance were likely limited due to fatigue, contributing to the improper train handling.

Fatigue management is a shared responsibility between individual employees and the company. Employees have a responsibility to make every effort to report to work well rested, and the company has a responsibility to provide a system that allows them to do so. The unscheduled nature of train operations can make it more difficult for employees to effectively manage their sleep, given that it can be difficult to predict when they will be required to report for work.

In this case, the LE was originally anticipating a call to go to work in the afternoon. However, after becoming aware that the train line-up had changed, the LE did not take an opportunity to sleep prior to accepting the overnight work period. If operating employees do not use the rest opportunities provided, there is a risk that trains may be operated by fatigued employees, increasing the risk of accidents.

Although the LE recognized that he was not properly rested, he did not use the unfit clause in the collective agreement to book unfit. This is despite the fact that the collective agreement states that employees will not be disciplined for using the unfit clause if they are unable to report for work in a rested state. If operating employees do not remove themselves from work when they are not adequately rested, trains may be operated by fatigued crew members, increasing the risk of accidents.

The LE had previously been disciplined in the form of a temporary suspension for pattern absenteeism. Consequently, he believed his continued employment would be in jeopardy if he did not accept the call. If railway industry fatigue management procedures do not provide opportunities for potentially fatigued employees to remove themselves from eligibility for duty without fear of discipline, there is an increased risk that fatigued employees will report for duty.

Canadian Pacific Railway internal investigation

The FMP commits the company to actively investigate fatigue following incidents and accidents in order to learn from these events and continually improve its fatigue management. Following this occurrence, CP conducted an internal investigation. However, CP's investigation did not effectively examine the employee's sleep history. Instead, it relied on asking the LE if he was rested and fit for duty, and CP did not carry out a fatigue analysis. Despite the fact that the LE was fatigued at the time of the occurrence, this was not identified by CP's incident investigation process, and a significant opportunity to examine and improve fatigue management practices was lost. If internal company investigations into situations where human performance may have played a role do not collect and analyze data related to employee sleep history, issues contributing to employee fatigue may go undetected and unmitigated, increasing the risk of fatigue-related accidents.

Findings

Findings as to causes and contributing factors

- The accident occurred when several wheels came off the rail while the train was operating through a 12-degree curve.

- The lateral-to-vertical forces at the wheel-rail interface reached a critical level where the car wheels climbed the inside rail.

- The tractive effort of the locomotives reached 135 000 pounds when the throttle was increased to position 6, which was above the maximum throttle position for that train in this area. At this point, the train brakes at the rear of the train had not started to release.

- Specific train-handling requirements relating to the use of the locomotive throttle for the occurrence location were not followed. Although the train crew members had a copy of the related bulletin, they did not review it prior to the train's arrival in Calgary.

- The locomotive engineer was likely fatigued due to poor-quality sleep in the 2 weeks prior to the occurrence and being awake for at least 23 hours at the time of the accident.

- The locomotive engineer's working memory and vigilance were likely limited due to fatigue, contributing to the improper train handling.

Findings as to risk

- If train crews do not review the relevant information relating to train operations in a given location prior to performing tasks at that location and if there is no other trigger to recall critical operational information, there is an increased risk of inappropriate train handling.

- If operating employees do not use the rest opportunities provided, there is a risk that trains may be operated by fatigued employees, increasing the risk of accidents.

- If operating employees do not remove themselves from work when they are not adequately rested, trains may be operated by fatigued crew members, increasing the risk of fatigue-related accidents.

- If railway industry fatigue management procedures do not provide opportunities for potentially fatigued employees to remove themselves from eligibility for duty without fear of discipline, there is an increased risk that fatigued employees will report for duty.

- If internal company investigations into situations where human performance may have played a role do not collect and analyze data related to employee sleep history, issues contributing to employee fatigue may go undetected and unmitigated, increasing the risk of fatigue-related accidents.

Safety action

Safety action taken

The TSB is not aware of any safety action taken following this occurrence.

This report concludes the Transportation Safety Board's investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .

Appendices

Appendix A – Locomotive engineer's work/rest history

Key:

- AD = awake and on duty

- A = awake and off duty

- BL = bereavement leave

- R = booked rest (unavailable to be recalled to work)

| Home Base Time -> | 0000 0100 |

0100 0200 |

0200 0300 |

0300 0400 |

0400 0500 |

0500 0600 |

0600 0700 |

0700 0800 |

0800 0900 |

0900 1000 |

1000 1100 |

1100 1200 |

1200 1300 |

1300 1400 |

1400 1500 |

1500 1600 |

1600 1700 |

1700 1800 |

1800 1900 |

1900 2000 |

2000 2100 |

2100 2200 |

2200 2300 |

2300 0000 |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Day | Date | ||||||||||||||||||||||||

| Tuesday | 2 Feb | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | ||||||||||||

| Wednesday | 3 Feb | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL |

| Thursday | 4 Feb | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL |

| Friday | 5 Feb | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL |

| Saturday | 6 Feb | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL | BL |

| Sunday | 7 Feb | BL | BL | BL | BL | BL | BL | BL | |||||||||||||||||

| Monday | 8 Feb | ||||||||||||||||||||||||

| Tuesday | 9 Feb | Call 0110 |

AD | AD | AD | AD | AD | AD | Off 0815 |

R | R | R | R | R | R (1415) |

||||||||||

| Wednesday | 10 Feb | Call 0055 |

AD | AD | AD | AD | AD | Off 0630 |

R | R | R | R | R | R | R | R | R | R | R | R | R | R | R | R | R |

| Thursday | 11 Feb | R | R | R | R | R | R (0529) |

Call 0950 |

AD | AD | AD | AD | AD | AD | AD | Off 1615 |

R | R | R | R | R | R (2215) |

|||

| Friday | 12 Feb | Call 0450 |

AD | AD | AD | AD | Off 0906 |

R | R | R | R | R | R | R | R | R | R | R | R | R | R | ||||

| Saturday | 13 Feb | R | R | R | R | R | R | R | R | R | R (0905) |

Call 1335 |

AD | AD | AD | AD | Off 1825 |

R | R | R | R | R | |||

| Sunday | 14 Feb | R | R | R (0215) |

Call 0800 |

AD | Off 1030 |

R | R | R | R | R | R | R | R | R | R | R | R | R | |||||

| Monday | 15 Feb | R | R | R | R | R | R | R | R | R | R | R (1029) |

Call 1700 |

Off 2300 |

R | ||||||||||

| Tuesday | 16 Feb | R | R | R | R | R | R (0500) |

Call 0700 |

AD | AD | AD | AD | AD | AD | Off 1215 |

R | R | R | R | R | R | R | R | R | |

| Wednesday | 17 Feb | R | R | R | R | R | R | R | A 0700 |

R | R | R | R | R | R | R (1214) |

Call 2220 |

AD | |||||||

| Thursday | 18 Feb | AD | AD | AD | AD | AD | AD | X 0623 |

|||||||||||||||||

Appendix B – Collective agreement provisions that allow time off between shifts

At Canadian Pacific Railway (CP), the collective agreement contains provisionsFootnote 35 allowing conductors and locomotive engineers to take time off between shifts in the following circumstances:

- Article 4.19: "Engineer on yard engine may have rest after having been 11 hours on duty. Engineer in yard service will give at least two hours notice of his desire to book rest."

- Article 5.09 (8): "Employees may book personal rest upon completion of RQ [rules qualification] training and will be paid lost earnings in accordance with the following:

Assigned Service Employees –

Shall be entitled to book up to 12 hours personal rest upon completion of RQ training and shall be entitled to lost earnings on other than the last day of training.

Note: Where RQ training is completed at other than the employee's home location, 12 hours personal rest may be booked upon arrival at the home location.

Unassigned Service Employees

Shall be entitled to book up to 24 hours personal rest upon completion of RQ training and shall hold their turn.

Note: Where RQ training is completed at other than the employee's home location, 24 hours personal rest may be booked upon arrival at the home location." - Article 10.03: "Engineers at the home terminal cancelled prior to commencing work will be entitled to book between five and eight hours rest."

- Article 27.01: "Employees will have the right to book up to 24 hours rest at home terminals and up to 8 hours rest at away from home terminals if desired. Such rest must be booked upon tie up. Employees will not be required to leave the terminal until they have had the amount of rest booked."

- Article 27.03: "Employees, being the judge of their own condition, may book rest after being on duty 10 hours, or 11 hours when two or more Brakepersons are employed on a crew in addition to the Conductor."

- Article 27.04: "Employees desiring rest en route will give their notice within the first 5 hours on duty to the Rail Traffic Controller or other designated Company employee. Notice will include the amount of rest required, 8 hours considered maximum at other than home terminal, except in extreme cases."

Employees may also book rest under the following circumstances pursuant to other provisions, as noted:

- Booking rest after vacation: letter from Alia Azim Garcia, Director Labour Relations, CP, June 17, 2010.

- Compassionate leave: 2007 Teamsters Canada Rail Conference (TCRC) Memorandum of Settlement, Appendix 11.

- 24 hours' rest booked at the home terminal: 2007 TCRC Memorandum of Settlement, Appendix 12.

- Home terminal rest (ability to have one's pool turn drop to the bottom of the board at the expiration of personal rest): 2007 TCRC Memorandum of Settlement, Appendix 12.

- Personal rest after being off for miles (OFM): 2012 TCRC Negotiated Changes, Rest After OFM.

- Earned days off: 2007 TCRC Memorandum of Settlement, Appendix 14.

- 48 hours off at mid-point and end of mileage period: 2015 Adams Award.