Main-track train collision and derailment

Canadian National Railway Company

Freight trains M31851-01 and M31541-03

Mile 50.37, Rivers Subdivision

Portage la Prairie, Manitoba

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Executive summary

On 03 January 2019, about 0610 Central Standard Time,Footnote 1 Canadian National Railway Company (CN) eastbound freight train M31851-01 (train 318) began following eastbound CN train Q11651-30 (train 116) near Rivers, Manitoba, on the CN Rivers Subdivision. Both trains were destined for Winnipeg, Manitoba. Train 318 was a key trainFootnote 2 operating on a key route,Footnote 3 as defined by the Transport Canada (TC)–approved Rules Respecting Key Trains and Key Routes.

At 0906:54, train 318 was travelling at 42 mph, with Trip Optimizer (TO) engaged and the throttle in position 7, as it passed a Clear to Stop signal indication at Mile 52.2. The conductor had called out the signal in the locomotive cab and identified the Clear to Stop indication. However, the conductor did not hear the locomotive engineer (LE) verbally respond to acknowledge the signal, and the LE appeared to be staring straight ahead. At this point, conversation in the cab ceased. TO remained engaged, and the train continued at track speed.

As CN train 318 was proceeding on the south track, a westbound CN freight train M31541-03 (train 315) was transitioning from single track to the north track while exiting the equilateral turnout (Mile 50.37) at Nattress near Portage la Prairie, Manitoba.

At Mile 51.13, while travelling at 46 mph, train 318 passed the head end of train 315. The train 318 conductor then reminded the LE that they were operating under a Clear to Stop indication. Once reminded, the LE disengaged TO and made a full service brake application at 0908:34; 24 seconds later, he inadvertently placed the brake handle into the suppression position (rather than the emergency position), and then applied the locomotive independent brake. After a further 10 seconds, as Stop Signal 504S came into view, the LE placed the train in emergency and the crew evacuated the locomotive cab.

Train 318 side-collided with train 315 while travelling at 23 mph (Figure S1). Shortly thereafter, the train 318 crew members jumped from the locomotive to the south side of the track and sustained minor injuries.

As a result of the collision, the 2 head-end locomotives on train 318 and 8 cars on train 315 derailed. Although no cars loaded with dangerous goods were involved, the head-end locomotives on train 318 lost a combined total of about 3500 imperial gallons of diesel fuel. The released diesel fuel was contained locally and cleaned up with no waterways affected.

The investigation concluded that:

- The train 318 crew had formed the expectation that they would follow train 116 clear through to Winnipeg, without stopping at Nattress, because that is what had happened on the previous 9 eastbound trips along the Rivers Subdivision.

- Train 318 had accelerated to 42 mph by the time it encountered Advance Signal 522S. From that point on, the train 318 crew should have been preparing to stop the train before arriving at Signal 504S at Nattress.

- The train 318 operating crew did not respond appropriately to the signal indications displayed in the field at Mile 52.2 and Mile 50.4, which ultimately led to the collision.

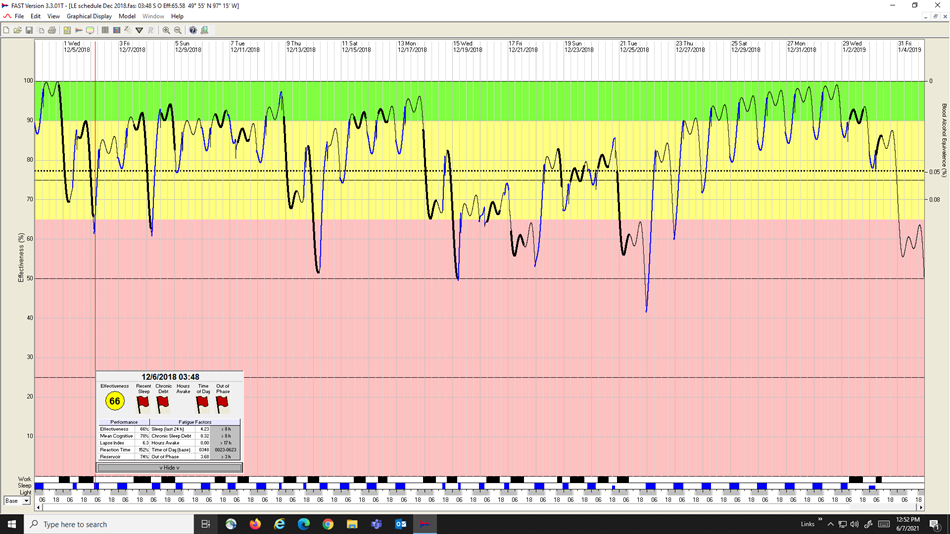

- The train 318 LE was fatigued due to acute sleep disruption brought on by abbreviated and disrupted sleep periods during the 2 nights preceding the accident.

- The train 318 LE experienced decreased vigilance due to the reduced workload while using TO and due to the performance decrements associated with his fatigue, which contributed to his delayed reaction to the restrictive signals at Mile 52.2, and to him selecting an inappropriate braking technique when initially trying to stop the train.

- Due to the inexperience of the train 318 conductor and the authority gradient that existed between the crew members, the conductor deferred to the LE without questioning the operation of the train and, as a result, the crew’s actions to slow and stop the train before Controlled Signal 504S were delayed and ineffective.

- In the absence of a physical defence such as an enhanced train control system, there was no automatic intervention to slow or stop the train when the crew did not initially respond to the Clear to Stop signal displayed in the field.

Safety action taken

Canadian National Railway Company

Following this occurrence, CN distributed System Notice No. 904 to all operating employees in Canada. The notice warned train crews that there had been an increase in Canadian Rail Operating Rules Rule 439 violations across the CN system because of train crews failing to stop at signal indications requiring them to do so, primarily due to a lack of focus on situational awareness. Notice No. 904 stated that “operating crews must not be influenced by other information such as train lineups, detector broadcasts or other crew’s [sic] broadcasts until they themselves positively identify the next signal.”

Safety action required

Enhanced train control for key routes

The basic design of centralized traffic control (CTC) signalling systems in Canada has been well established for some time. Although newer signal circuitry has been integrated into the CTC system over the years, railway operations still rely predominantly on administrative defences, which are the least effective method for mitigating risk. Administrative defences place an over-reliance on a train crew to follow the rules and do not consider the human factors that affect behaviour. For example, the CTC train control system in this case had the administrative requirement for train crews to follow the signal indications displayed in the field, yet this defence did not prevent the accident from occurring.

A signalled CTC system does not provide any advance warning to either the train crew or the rail traffic controller. CTC also does not provide automatic enforcement to comply with speed restrictions in order to slow or stop a train before it passes a restrictive signal. As a result, when a train crew misperceives, misinterprets or does not follow a signal indication, the administrative defences as a whole fail. As demonstrated in this and 80 other TSB investigations since 1990, when an administrative defence fails and there is no secondary defence, it can result in an accident that otherwise could have been prevented.

For comparison, Class 1 railways that operate in the United States (U.S.) have implemented physical fail-safe train control systems known as positive train control (PTC). PTC is designed to prevent train-to-train collisions, overspeed derailments, incursions into work zones, and movement of a train through a switch left in the wrong position. In Canada, the term “enhanced train control” (ETC) has been adopted to describe such systems.

A PTC/ETC system would address the risk of crews misinterpreting or not following signal indications by automatically intervening to slow or stop a train in the event that an operating crew does not respond appropriately to a signal displayed in the field. A fully functioning PTC/ETC system would also offer a physical fail-safe defence against operating crew errors that are influenced by fatigue, which played a role in this accident.

In the U.S., the Rail Safety Improvement Act (RSIA) of 2008 required that PTC be installed on high-hazard routes; as of 31 December 2020, PTC was fully implemented on all required track, a total of 57 535.7 miles, or about 41% of the nearly 140 000 route-miles of the U.S. rail network. The total miles of track that have PTC installed includes the U.S. operations of both CN (3107 miles) and Canadian Pacific Railway Company (CP) (2118 miles).

In comparison, the Canadian rail network comprises about 26 000 route-miles of track. Key routes account for a combined total of about 10 940 miles of main track, which represents about 42% of the Canadian rail network. However, in contrast to the U.S., there is no requirement to install PTC or ETC on routes that carry dangerous goods in Canada.

Since 2000, the Board has issued 2 recommendations related to the need for additional train control defences:

- Recommendation R00-04 was issued following its investigation into the 1998 collision between 2 CP trains near Notch Hill, British Columbia.Footnote 4 The Board recommended that the railway industry implement additional backup safety defences to help ensure that signal indications are consistently recognized and followed.

- Recommendation R13-01 was issued following a TSB investigation into the 2012 derailment and collision of VIA Rail Canada Inc. passenger train 92 (VIA 92) near Burlington, Ontario.Footnote 5 The Board recommended the implementation of physical fail-safe train controls, beginning with Canada’s high-speed rail corridors.

In 2014, in response to the 2 TSB recommendations, a joint TC–industry train control working group (TCWG) was established and contracted a report from the Canadian Rail Research Laboratory (CaRRL). After these activities, there were a series of ongoing meetings, discussions, and studies related to the development and implementation of ETC systems in Canada with no implementation plan or other tangible results to date. While TC did publish a Notice of Intent in the Canada Gazette, Part I, in February 2022 signalling its intent to require the implementation of ETC in Canada, there is still no implementation plan. In the time it took TC and industry to strike the TCWG, study the issue, produce the TCWG Final Report, contract a follow-on report from the CaRRL and study the CaRRL results, PTC had been fully implemented in the U.S. on all of the high-hazard trackage required by the RSIA legislation.

The CN Rivers Subdivision is a key route and is also an integral part of one of the major rail traffic corridors in Canada. This also means that the cities, towns, and villages along this key route are continually exposed to the risks associated with key trains transporting dangerous goods (DG). Any collision or derailment involving a key train presents a risk of a DG release and potential adverse consequences to people, property or the environment.

The implementation of physical fail-safe train control technologies such as ETC would provide an extra layer of safety when operated in conjunction with existing administrative defences. However, the Canadian railway industry continues to rely solely on administrative defences to protect against train crews not responding appropriately to signal indications displayed in the field.

If TC and the railway industry do not take action to implement physical fail-safe defences to reduce the consequences of inevitable human errors, the risk of collisions and derailments will persist, with a commensurate increase in risk on key routes in Canada. Therefore, the Board recommends that

the Department of Transport require major Canadian railways to expedite the implementation of physical fail-safe train controls on Canada’s high-speed rail corridors and on all key routes.

TSB Recommendation R22-04

Recurrent crew resource management training

In general, railway companies do not use closed-loop communication methods. Rail operating rules require that when a train encounters a signal indication displayed in the field, 1 crew member must communicate the signal indication aloud within the locomotive cab to the other crew member. While the other crew member is required to repeat the message back, there is no requirement for the original sender to confirm that the message was received accurately or understood by the other crew member.

As demonstrated by this occurrence, when there is a significant difference in level of experience between operating crew members, an authority gradient may develop in which the less experienced crew member may not always intervene to ensure compliance with all of the rules. In these situations, there is a danger that safety-compromising behaviour will be overlooked because a less experienced employee may be reluctant to question the actions of a more senior employee or intervene in the operation of the train even when it may be critical to do so, such as occurred in this accident.

Crew resource management (CRM) is a concept introduced in the aviation and marine industries to limit or eliminate human errors by recognizing the importance of cognitive and interpersonal skills, thereby improving safety. CRM training seeks to improve a crew’s skills, abilities, attitudes, communication, situational awareness, problem solving, and teamwork. Crew members must successfully interact with each other, their equipment, and their environment to effectively manage threats, errors, and unexpected conditions that may be encountered.

Crew actions need to be based on a common understanding of the state of the equipment, the intended route to be taken, and any other potential threats. When this understanding is consistent, crews are better able to effectively anticipate and coordinate their actions to achieve their common goal. This common understanding between crew members is referred to as team or shared situational awareness.

Shared situational awareness is developed and maintained by a crew through a number of discrete and continuous behaviours. These behaviours include in-trip briefings, the identification of key points throughout the trip, threat and error management (TEM), callouts to any change in the state of the equipment, the instrument setting or mode, and the communication of any change in plans to ensure that all crew members have a common understanding of activities.

CRM training teaches personnel to approach their activities from a team perspective rather than from an individual perspective. Significant safety benefits were experienced in the aviation and marine industries with the introduction of CRM. Given the prevalence of human factors in rail accident statistics, this type of training could yield significant safety benefits in the rail industry.Footnote 6

However, the adoption of CRM training in the rail industry has been sporadic and the approach differs between railways. Similarly, the Railway Employee Qualification Standards Regulations have no requirement for operating crews to complete a separate module on CRM when they qualify or re-qualify in accordance with the regulations.

The TSB has investigated 8 other rail occurrences, dating back as far as 1996, where ineffective CRM practices were identified as a factor that contributed to the accidents.Footnote 7

If operating crew members do not receive enhanced initial and recurrent CRM training to develop skills in crew communication, the coordination of decision making and activities, and dealing with authority gradients that may exist within a locomotive cab environment, there is an increased risk that inadequate crew communication will lead to unsafe operations. Therefore, the Board recommends that

the Department of Transport require, under the Railway Employee Qualification Standards Regulations, Canadian railways to develop and implement modern initial and recurrent crew resource management training as part of qualification training for railway operating employees.

TSB Recommendation R22-05

1.0 Factual information

1.1 Canadian National Railway Company freight train Q11651-30

Eastbound Canadian National Railway Company (CN) freight train Q11651-30 (train 116) originated in Roberts Bank, British Columbia.Footnote 8 Train 116 consisted of 2 head-end locomotives hauling 137 loaded intermodal cars. It was 9210 feet long and weighed 8106 tons. On 03 January 2019, a crew was ordered for 0400Footnote 9 for train 116 at Rivers, Manitoba, located at Mile 143.2 of the Rivers Subdivision. Train 116 departed Rivers at about 0445, destined for Winnipeg, Manitoba.

1.2 Canadian National Railway Company freight train M31851-01

Eastbound CN freight train M31851-01 (train 318) originated in Edmonton, Alberta, and was destined for Winnipeg. It was classified as a key trainFootnote 10 according to the Transport Canada (TC)–approved Rules Respecting Key Trains and Key Routes. The power for train 318 consisted of four 6-axle road locomotives. There were 3 locomotives on the head end and 1 distributed power (DP) remote locomotive located at Line 99; the 1st, 2nd and DP locomotives were on-line while the 3rd head-end locomotive was isolated. Train 318 was hauling 160 cars (134 loaded and 26 empty), which included 33 loaded dangerous goods (DG) tank cars and 6 residue DG tank cars.Footnote 11,Footnote 12 It was 9613 feet long and weighed 19 275 tons.

At 0430 on 03 January 2019, a CN operating crew was ordered for train 318 in Rivers. The crew consisted of a locomotive engineer (LE) and a conductor. The LE was familiar with the subdivision; the conductor had transferred to Winnipeg in October 2018. Between 04 November 2018 and 03 January 2019, the conductor had completed the requisite 2 familiarization trips and 29 other tripsFootnote 13 over the Rivers Subdivision.

Both crew members were qualified for their positions and met fitness requirements. Their work histories were in compliance with the TC–approved Work/Rest Rules for Railway Operating Employees (Work/Rest Rules). At about 0610, train 318 departed from the Rivers Yard eastbound on the Rivers Subdivision, which is also a key routeFootnote 14 (Figure 1). The train 318 crew operated the train from the lead locomotive (CN 3009).

1.3 Canadian National Railway Company freight train M31541-03

Westbound CN freight train M31541-03 (train 315) originated in Winnipeg and was destined for Edmonton. There were 5 locomotives on the head end; 2 locomotives were on-line and the remaining 3 locomotives were isolated. Train 315 was hauling 136 cars (57 loaded and 79 empty), which included 9 tank cars loaded with DGFootnote 15 and 52 DG residue tank cars.Footnote 16 It was 9189 feet long and weighed 8301 tons.

At 0530 on 03 January 2019, a CN operating crew was ordered for train 315 at Winnipeg, located at Mile 0.0 of the Rivers Subdivision. The crew consisted of an LE and a conductor. Both crew members were qualified for their positions and met regulatory fitness and rest requirements. At about 0730, train 315 departed westbound from Winnipeg on the Rivers Subdivision.

1.4 Train activity on the Rivers Subdivision before the accident

Eastbound train 116 departed Rivers at 0445 ahead of train 318, which departed Rivers Yard at approximately 0610.

Throughout the duration of the trip, train 318 was operated in Trip Optimizer (TO)Footnote 17 mode three times:

- between 0610 (Mile 142.6) and 0620 (Mile 136.7);

- between 0700 (Mile 126.8) and 0740 (Mile 96.1);

- between 0900 (Mile 56) and 0908 (Mile 51.4).

As train 318 approached Elk Crossing (Mile 89.9), it started to receive Advance Clear to Stop and Clear to StopFootnote 18 signal indications until just west of Bloom (Mile 64.3). In response to these restrictive signals, braking action was delayed in anticipation of a less restrictive signal being displayed. As anticipated, these signals changed to a Clear signal before train 318 passed.

Train 318 stopped at the Bloom west siding switch behind train 116, which was stopped at the Bloom east siding switch for a meet with another westbound train. Since both train 318 and train 116 were in close proximity, the train 318 crew overheard the train 116 crew calling signal indications on the radio and the automated hot box detectors broadcasting automated talker reports on the radio.

When the westbound train 315 cleared into the siding at Bloom, train 116 received a Clear signal indication to depart eastward, and train 318 followed up to the Bloom east siding switch governed by a Clear to Stop signal indication requiring that the crew be prepared to stop at the next signal. Train 318 subsequently received a Clear signal indication at the Bloom east siding switch and departed Bloom after train 116 had cleared 2 blocks aheadFootnote 19 in the direction of travel.

After passing a Clear signal indication at West Tower (Mile 56.1), train 318 was placed in TO mode and received Clear signal indications at the next 2 stations of Kearns (Mile 55.7) and Portage la Prairie (Mile 55.3), Manitoba, respectively.

As train 318 approached Portage la Prairie, the train 318 crew overheard a radio conversation between the rail traffic controller (RTC) and train 116. During the conversation, it was indicated that train 116 had been lined right through to St. James Junction, which meant that train 116 would be cleared straight to Winnipeg without any additional train meets.

In light of the conversation between the RTC and train 116, the train 318 crew expected that they would continue to follow train 116 straight into Winnipeg without stopping; any westbound traffic train 318 might encounter would likely have been stopped at Nattress (Mile 50.4), as was the case for the train 318 crew’s most recent trips. However, unknown to the train 318 crew, the RTC had planned to hold train 318 at Nattress to allow westbound train 315 to pass after train 116 had cleared Nattress. As train 318 continued on the south main track, the LE continued to operate the train with TO engaged.

During the trip eastward, the train 318 conductor regularly called out the signal indications displayed in the field within the locomotive cab as required by Rule 34(b) of the Canadian Rail Operating Rules (CROR).Footnote 20 However, the conductor did not always hear the LE verbally respond to acknowledge the signal indication. In addition to their normal work duties, the LE and the conductor engaged in conversation about the Rivers Subdivision because the conductor was still learning details about the territory.

1.5 The accident

At about 0903, while proceeding at 31 mph with the throttle in position 5, train 318 encountered Controlled Signal 542S (Mile 54.2),Footnote 21 which displayed a Clear to Limited indication. The signal indication identified that the train could “[p]roceed, approaching next signal at LIMITED speed.”Footnote 22 Limited speed is defined as “[a] speed not exceeding 45 miles per hour.”Footnote 23 The conductor called out the signal indication in the cab and the LE responded and verbally acknowledged it. The train continued with the TO feature engaged and the air brake pipe pressure steady at 89 psi. Conversation in the cab continued.

Between 0903:26 and 0906:01, the train horn was sounded in advance of the crossings at Mile 54.22, Mile 53.58, and Mile 52.89.

At about 0906, while at the Mile 52.89 crossing, the train 318 conductor observed Advance Signal 522S (Mile 52.2), which was the next signal in the progression. Signal 522S displayed a Clear to Stop indication.Footnote 24 The conductor called out the Clear to Stop indication displayed by Advance Signal 522S in the locomotive cab as the headlight from westbound train 315 that was travelling on the north track came into view. However, the conductor did not hear the LE verbally respond to acknowledge the signal. The LE appeared to be staring straight ahead and unresponsive. At this point, conversation in the cab ceased. The TO remained engaged, and the train continued at track speed.

At 0906:54, eastbound train 318 was proceeding on the south main track at 42 mph with the throttle in position 7 as it passed the Clear to Stop indication (Mile 52.2) while westbound train 315 was proceeding on the north main track at about 38 mph. At this time, the train 318 TO was engaged and the air brake pipe pressure was 89 psi. Normally, the LE would disengage TO after passing an indication other than Clear, but in this instance, he did not.

At 0907:36, while the train was proceeding at 44 mph and as was normal practice, the LEs on both train 318 and train 315 extinguished their lead locomotive headlights as they approached each other. On train 318, TO remained engaged, the throttle was in position 6, and the air brake pipe pressure was 89 psi.

At 0908:22, the head-end locomotives of both train 318 and train 315 passed each other at Mile 51.13, just past a private farm crossing located at Mile 51.3. As this occurred, the train 315 crew noted that train 318 was approaching at a higher than expected speed. At about the same time, the train 318 conductor reminded the LE that they were proceeding on a Clear to Stop indication. The LE initially seemed unresponsive but then appeared to regain awareness. The LE had no recollection of the conductor calling the Clear to Stop signal in the cab nor of the events that subsequently transpired until the conductor reminded him that they were proceeding on a Clear to Stop indication. At that time, the train 318 TO remained engaged, the throttle was in position 6, the air brake pipe pressure was 89 psi, and the headlight remained off.

At 0908:33, train 318 was proceeding at 46 mph at Mile 50.99 when the LE disengaged TO in order to assume manual operating control of the train.

At 0908:34, with the air brake pipe pressure at 88 psi, the LE reduced the throttle to idle and went directly to a full service brake application (reduction of 25 psi) using the automatic brake handle to apply the train automatic air brakes.

At 0908:58, train 318 was proceeding at 43 mph at Mile 50.68. The throttle remained in idle and the air brake pipe pressure was 68 psi. The LE intended to place the automatic air brake handle into the emergency position but inadvertently placed it into the suppressionFootnote 25 position. At the time, train 318 was quickly approaching the Nattress main track equilateral turnoutFootnote 26 at Mile 50.37, where the double main track transitions to a single main track (between Mile 50.37 and Mile 50.1) and the track traverses the Assiniboine River.

At 0909:00, train 318 was proceeding at 39 mph at Mile 50.66 when the LE noticed that the train was not slowing sufficiently and applied the locomotive independent brakes (IB). The throttle remained in idle, the train air brake pipe pressure was 67 psi, and the locomotive brake cylinder pressure was 1 psi. At about this time, the train 318 LE called the train 315 crew to ask them to increase their speed in order for train 315 to clear the turnout more quickly.

At 0909:06, train 318 was proceeding at 39 mph at Mile 50.59 when the locomotive IB were fully applied. The throttle remained in idle, the air brake pipe pressure was 64 psi, and the locomotive brake cylinder pressure was 70 psi.

At 0909:08, train 318 was proceeding at 39 mph at Mile 50.57 when the LE activated the emergency toggle on the input and display unit (IDU), initiating a train emergency brake application from the sense and braking unit (SBU)Footnote 27 at the end of the train (EOT). At this time, the throttle remained in idle, the air brake pipe pressure was 63 psi (full service application), the head-end locomotive brake cylinder pressure was 70 psi, the EOT brake pipe pressure was 73 psi, and Signal 504S would have just become visible from the locomotive cab. This pressure differential between the head end and EOT indicated that the full service brake application had not yet fully propagated to the tail end of train 318.

The LE called to the conductor to get out, then grabbed him in preparation to evacuate. The LE and the conductor subsequently evacuated the locomotive cab through the right-side rear door located behind the LE control stand onto the locomotive platform.

At 0909:17, with train 318 proceeding at 34 mph at Mile 50.48, the air brake pipe pressure had dropped to 0 psi at both the head end and tail end of the train, which indicated that the train brakes were fully applied in emergency throughout the train.

At 0909:26, train 318 passed Signal 504S (Mile 50.4), which displayed a Stop indication, while travelling at 27 mph.

At 0909:30, while train 318 was proceeding at 23 mph, it side-collided with the 95th car of train 315 at Mile 50.37 (Figure 2). Shortly after the collision, the crew members jumped from the locomotive to the south side of the track.

By about 0910:00, the lead locomotive of train 318 had derailed and come to a stop on the south side of the track at approximately Mile 50.33.

During their egress, the train 318 crew members sustained minor injuries. They were transported to hospital where they were treated and released.

At the time of the accident, the temperature was about 3 °C with 13 km/h winds from the southwest. The skies were overcast and visibility was good.

1.6 Site examination

The 2 lead head-end locomotives on train 318 (CN 3009 and GECX 7371) both remained mainly upright but had derailed all wheels. The lead locomotive (CN 3009) came to rest at about a 45-degree angle from the track, partway down the south embankment. The north side of both locomotives had sustained damage. Lead locomotive CN 3009 was extensively damaged (Figure 3) while GECX 7371 exhibited some impact damage and scrapes. The fuel tanks on both locomotives were punctured, which resulted in the loss of a combined total of about 3500 imperial gallons (15 911 litres) of diesel fuel. The fuel was contained locally during site remediation and was subsequently cleaned up. No waterways were affected.

On train 315, the 95th to 102nd cars (inclusive) behind the head-end locomotives were derailed. The 95th and 102nd cars remained upright while the 96th to 101st cars were derailed onto their side (Figure 4). All train 315 derailed cars displayed various forms of impact damage sustained during the accident. Two empty non-DG Class DOT 111 tank cars were located in the 95th and 96th positions (UTLX 204215 and UTLX 204234). The south side of the 95th car tank shell was punctured, and the 96th car was derailed onto its side but was not punctured. Although it is not unusual for empty tank cars to have residue product remaining inside, no product was released during the accident.

1.7 Recorded information and train 318 crew actions

Table 1 provides a summary of the events, including train 318 crew actions, based on the review of the locomotive event recorder (LER) data from train 318 lead head-end locomotive CN 3009 and the forward-facing video camera recordings from both train 318 and train 315.

| Time | Train speed (mph) | Mile | Event / train 318 crew actions | Distance from Controlled Signal 504S at Mile 50.4 |

|---|---|---|---|---|

0903:26 |

30 | 54.29 |

The train horn began sounding 0.13 miles in advance of the crossing at Mile 54.22 while travelling at 30 mph and lasted 15 seconds.* |

3.89 miles |

0903:37 |

31 | 54.2 |

The head end of train 318 passed East Tower Controlled Signal 542S (Mile 54.2), which displayed a Clear to Limited indication. TO was on, the throttle was in position 5, and the air brake pipe pressure was 89 psi. |

3.8 miles |

0904:27 |

33 | 53.75 |

The train horn began sounding 0.26 miles in advance of the crossing at Mile 53.58 while travelling at 33 mph and lasted 27 seconds. |

3.35 miles |

0905:58 |

39 | 52.83 |

The train horn began sounding at the crossing at Mile 52.89 while travelling at 39 mph and lasted 3 seconds. |

2.43 miles |

0906:54 |

42 | 52.2 |

The head end of train 318 passed Advance Signal 522S (Mile 52.2), which displayed a Clear to Stop indication. TO was on, the throttle was in position 7, and the air brake pipe pressure was 89 psi. |

1.8 miles |

0907:36 |

44 | 51.7 |

The LE turned off the headlight for a meet with train 315. The train 318 TO was on, the throttle was in position 6, and the air brake pipe pressure was 89 psi. |

1.3 miles |

0908:22 |

46 | 51.13 |

The head-end locomotives of train 318 and train 315 met just past a farm crossing (Mile 51.3). The train 318 TO was on, the throttle was in position 6, and the air brake pipe pressure was 89 psi. The headlight remained off and the horn was not sounded. |

0.73 miles |

0908:33 |

46 | 50.99 |

The LE disengaged TO. |

0.59 miles |

0908:34 |

46 | 50.98 |

The LE reduced the throttle to idle and initiated a full service brake application (25 psi) to apply the train automatic air brakes. The air brake pipe pressure was 88 psi. |

0.58 miles |

0908:58 |

43 | 50.68 |

The automatic air brake handle was placed into the suppression position. The throttle remained in idle, and the air brake pipe pressure was 68 psi. |

0.28 miles |

0909:00 |

39 | 50.66 |

The locomotive IB were initially applied. The throttle remained in idle, the air brake pipe pressure was 67 psi, and the locomotive brake cylinder pressure was 1 psi. |

0.26 miles |

0909:06 |

39 | 50.59 |

The locomotive IB were fully applied. The throttle remained in idle, the air brake pipe pressure was 64 psi, and the locomotive brake cylinder pressure was 70 psi. |

0.19 miles |

0909:08 |

39 | 50.57 |

The LE activated the IDU, which initiated an emergency brake application from the SBU on the EOT. The throttle remained in idle, the air brake pipe pressure was 63 psi, the locomotive brake cylinder pressure was 70 psi, and the EOT brake pipe pressure was 73 psi. |

0.17 miles |

0909:17 |

34 | 50.48 |

Train 318 air brake pipe pressure dropped to 0 psi at the head end and tail end, which indicated that the train emergency brakes were fully applied. |

0.08 miles |

0909:26 |

27 | 50.4 |

Train 318 passed Controlled Signal 504S (Mile 50.4). |

0 miles |

0909:30 |

23 | 50.37 |

The lead locomotive (CN 3009) of train 318 side-collided with the 95th car on train 315 and derailed. |

−0.03 miles |

About 0910:00 |

0 | 50.33 |

The derailed lead locomotive (CN 3009) of train 318 came to rest. |

−0.07 miles |

* For trains travelling in excess of 44 mph, Rule 14(l) of the Transport Canada–approved Canadian Rail Operating Rules requires the locomotive horn to be sounded, from the whistle post positioned ¼ mile in advance of a public crossing until the crossing is fully occupied, by using 2 long, 1 short, and 1 long whistle. For trains travelling 44 mph or less, the horn sounding must provide at least 20 seconds of warning prior to entering the crossing.

1.7.1 Locomotive voice and video recorders

The use of in-cab locomotive voice and video recorders (LVVR) is an objective and reliable method of more clearly determining the role that human factors, such as crew intra-cab communication, distraction and fatigue, may play in a railway occurrence. Although TC has developed the Locomotive Voice and Video Recorder Regulations that identify the technical requirements for the LVVR equipment and the privacy protections for employees, the new LVVR Regulations will not fully come into force until 02 September 2022.

Because there was no in-cab LVVR in use, the events in the cab could not be immediately confirmed and the train’s process through Signal 504S, which displayed a Stop indication, could not be quickly explained.

1.8 Train braking systems

Locomotives are equipped to manage 2 air brake systems: the train automatic brakes and the locomotive IB.

The automatic brake system applies the brakes to each car and locomotive on the train, and is normally used for service brake applications and emergency brake applications during train operations to slow and stop the train.

The locomotive independent air brake system applies brakes only on the locomotives. It is primarily used to control locomotive speed when switching, to control or stop a train when travelling below 15 mph, and to stop locomotive wheel slips. The IB is generally not used during main line train operations.

Each freight car is equipped with a service brake valve and an emergency brake valve. A car’s air brake system is further equipped with an accelerated application valve (AAV) and a quick service feature that directly exhausts air brake pipe pressure and provides a faster service brake application.

CN 3009 is a General Electric model ET44AC locomotive built in August 2015, capable of producing up to 4400 HP. It is equipped with train controls placed on a control stand located to the left of the LE seat (Figure 5). The automatic brake handle is located on the left side of the control stand and is identified by the red handle.

1.8.1 Automatic brakes (service brake application)

A train’s automatic brake system is supplied with air from compressors located on each operating locomotive. The air is stored in the locomotive’s 2 main reservoirs. Number 2 main reservoir supplies approximately 90 psi of air to a brake pipe that runs along the length of the entire train, connecting to each locomotive and individual car. During operation, the locomotive compressors charge the train air brake pipe as needed. Air pressure reduction within this brake pipe activates the brakes on the entire train.

To make a service brake application, an LE moves the automatic brake handle to the desired position (Figure 6).

Internally, the handle positions are notched so that there is a natural stop at each position; additional effort is needed to move the handle to the next position. LEs are trained to place a train into emergency by moving the automatic brake handle to the right, as far as it will go, until it encounters a stop.

To activate the air brakes, air is removed from the brake pipe. As each car’s service air brake valve senses the pressure reduction, it allows air to flow from a reservoir located on each car into that car’s brake cylinder, applying the brake shoes to the wheels.

To release the brakes, the LE moves the automatic brake handle to the release position. This causes air to flow from the No. 2 main reservoir on the locomotive into the brake pipe, restoring pressure to 90 psi throughout the train air brake pipe. Subsequently, as each car senses an air brake pipe pressure increase, its service air brake valve allows air to be released from its brake cylinder, and the brake shoes are removed from the wheels.

1.8.1.1 Split-service brake application

When making a service brake application, CN’s LEs are trained to use a split-service brake application to take advantage of the freight car air brake AAV and quick service feature. A split-service brake application requires an initial minimum reduction of 7 psi in the brake pipe, which activates the AAV and quick service feature on the freight car air brake valves. The LE monitors the IDU in the locomotive cab and once air pressure begins to reduce at the EOT, the LE makes a second reduction to complete the service brake application to the desired level, up to a total air pressure reduction of 25 psi in the brake pipe.

If an LE goes directly to a full service brake application, the AAV action and quick service feature that directly exhaust air brake pipe pressure locally at each car are bypassed. When these features are bypassed, the air brake pipe pressure exhausts only from the control valves on the head-end and remote locomotives. This subsequently delays the air brake pipe pressure reduction and corresponding service brake application and brake cylinder pressure build-up.

1.8.2 Locomotive independent brakes

The locomotive IB are also supplied with air from the No. 2 main locomotive air reservoir. When an IB application is required on a 6-axle road locomotive, an LE moves the IB handle, which, in turn, injects up to 72 psi of air pressure directly from the No. 2 main reservoir into the brake cylinders of the locomotive. This causes the brake shoes to apply to the wheels.

To release the IB, an LE moves the IB handle to the release position. This causes air to be released from the locomotive’s brake cylinders, and the brake shoes are removed from the wheels.

1.8.3 Emergency brake application

An emergency brake application is the maximum application of a train’s air brakes, during which the brake pipe pressure is rapidly reduced to 0 psi, either from a separation of the brake pipe or train crew-initiated action. In either case, once a train goes into emergency, the air brake pipe pressure reduction propagates throughout the train air brake pipe. As the air brake pressure reduction propagates, the air is directly exhausted from the locomotive brake valves and locally at each car through its emergency brake valve. The exhausting air makes a distinct sound that is clearly audible within a locomotive cab. As well, the pneumatic control switch (PCS) open light illuminates (red) on the locomotive main screen display, the tail-end air brake pipe pressure indicates 0 (red), the equalizing No. 2 reservoir pressure indicates 0 (red), the locomotive brake pipe pressure indicates 0 (red), a message indicating the emergency brakes have been applied appears (yellow) and, on the occurrence locomotive, the overhead cab light illuminates (red).

The CN Locomotive Engineer Operating ManualFootnote 28provides train handling instructions for LEs. Regarding the application of the emergency brakes, section G2.8 Emergency Brake Application states the following in part:

In response to any emergency brake application (including UDE):Footnote 29

- The emergency toggle switch on the IDU must be activated to initiate an emergency application from the rear of the train,

- The throttle must be moved to IDLE, and

- The automatic brake valve handle must remain in EMERGENCY position until the train stops.

After the train has stopped, wait for the PC [power cut out] to reset (60 to 90 seconds). When safe to do so, move the automatic brake valve to the RELEASE position.

To prevent wheel slide or excessive in-train (buff or draft) forces during an emergency brake application, use the following procedure to regulate locomotive brake cylinder pressure:

Head-End Stretched

- (i) Until the train brakes become effective, keep the independent brake handle in the RELEASE position while actuating to maintain head-end slack stretched.

1.8.3.1 Company follow-up for train emergency brake applications

When a CN train goes into emergency, whether train-initiated or crew-initiated, select railway managers receive instant notification, and the information from the train is downloaded. This allows managers to react immediately to a potential emergency and evaluate the operation of the train.

1.8.4 Penalty brake application

A penalty brake application is similar to a full service brake application but occurs as a result of a “penalty” applied by the system. This type of braking reduces the brake pipe pressure to 0 psi, requiring a moving train to stop and recharge the brake pipe in order to recover from the penalty brake application.

Penalty brake applications can be initiated when a locomotive overspeedFootnote 30 occurs, or when an LE fails to respond to the reset safety control (RSC) alertFootnote 31 and does not reset the RSC. A penalty brake application reduces the air brake pipe pressure to 0 psi, but does not deplete all of the air in each car’s reservoir.

1.8.5 Suppression

The suppression position is at a specific location on the locomotive’s automatic brake valve handle. It provides a full service brake application of the brake pipe pressure, since the brake valve handle has already moved through the full service zone in order to reach this position. The propagation rate of the air pressure reduction through the brake pipe when the brake valve handle is placed in the full service zone or the suppression position is the same; both are less than the propagation rate during an emergency application of the brakes. Suppression is used to suppress or recover from penalty brake applications.

As a result of a penalty brake application, a train is brought to a stop. The automatic brake handle must then be placed and left in the suppression position for 60 seconds in order to recover from the penalty brake application and be able to charge the brake system once again.

When operating with a fully charged brake pipe, placing the automatic brake handle into the suppression position during regular train operations does not provide any additional braking force compared to a full service brake application. At no time should suppression be used when a train is moving.

1.9 Stopping distance calculations and observations

The LER data were reviewed, and braking calculations were made to verify the braking function of train 318 and estimate various stopping distances. It was determined that the train 318 air brakes were fully functional at the time of the accident.

Advance Signal 522S (Mile 52.2), which displayed a Clear to Stop indication, and Controlled Signal 504S (Mile 50.4), which displayed a Stop indication, are located 9504 feet apart.

1.9.1 Estimated stopping distances using alternate train handling scenarios

Additional calculations provided estimated stopping distances for train 318 for various train handling techniques to bring the train to a stop from the speeds of 46 mph and 39 mph respectively, if no accident occurred.

The estimated braking distances are conservative and based on the make-up (train length, total tonnage and distributed power [DP] configuration) of train 318. The calculations are based on reasonable assumptions using industry-wide accepted air brake stopping distance formulas. The calculations assume there was an initial air brake pipe (BP) pressure of 89 psi and include estimated air brake propagation time throughout the train as well as brake cylinder build-up time for each car.

The calculations also assume that the mid-train DP remote locomotive would propagate either a service or an emergency brake application signal forward and backward, as it receives the radio signal from the lead locomotive. The air brake application on the front half of the train ahead of the DP remote locomotive would take the least amount of time to activate as air propagates backward from the lead locomotive and forward from the DP remote locomotive simultaneously.

For service brake applications, the following assumptions were made:

- Each car takes approximately 0.30 seconds to develop full brake cylinder pressure for a full service application.

- The service air brake propagation signal travels throughout the air brake pipe at about 600 feet/second.

For a split-service brake application, the following assumptions were made:

- The split-service brake application would activate the AAV and quick service feature of the freight car brakes, which would reduce brake cylinder build-up time slightly to about 0.25 seconds per car.

- The service air brake propagation signal travels throughout the air brake pipe at about 600 feet/second.

For emergency brake applications, the following assumptions were made:

- Each car takes approximately 0.1 seconds to develop full brake cylinder pressure.

- The emergency air brake propagation signal travels throughout the air brake pipe at about 900 feet/second.

Assumptions for the calculations used for estimating stopping distances are outlined in the scenarios below:Footnote 32

- A full service brake application (air brake pipe pressure reduction of 25 psi) is activated using the automatic brake handle only. The estimated stopping distances assume a total of 32.5 seconds for air brake propagation time throughout the train and the brake cylinder build-up time for each car.

- A split-service automatic brake application requires an initial minimum reduction of 7 psi to activate the AAV and quick service feature on the freight car air brake valves, followed by a further reduction of 18 psi for a total air brake pipe pressure reduction of 25 psi. The estimated stopping distances assume a total of 28.75 seconds for air brake propagation time throughout the train and brake cylinder build-up time for each car.

- A full emergency brake application is performed using the automatic brake handle in conjunction with activating the toggle on the IDU to initiate a simultaneous emergency brake application from the EOT.Footnote 33 Because the emergency application is activated from 2 locations, 1 on either end of the train, the air brake propagation time throughout the train and the brake cylinder build-up time for each car is reduced to 8.4 seconds of total activation time.

The estimated stopping distances, for scenarios 1 to 3, from 46 mph and 39 mph respectively, are contained in Table 2.

| Scenario | Braking assumption | Estimated time to activate full brake (seconds) |

Speed (mph) | Estimated stopping distance (feet) |

|---|---|---|---|---|

1 |

Full service brake application (25 psi BP reduction) |

32.5 |

46 | 4744 |

| 39 | 3778 | |||

2 |

Split-service brake application (initial reduction of 7 psi followed by a further reduction of 18 psi for a total reduction of 25 psi) |

28.75 |

46 | 4416 |

| 39 | 3499 | |||

3 |

Emergency brake application with head-end and IDU EOT activation |

8.4 |

46 | 2316 |

| 39 | 1760 |

1.10 Rivers Subdivision and track information

The CN Rivers Subdivision extends from Mile 0.0 at Winnipeg, westward to Mile 280.30 at Melville, Saskatchewan. It is part of one of CN’s main traffic corridors and consists of both double and single track. Train movements on this subdivision are governed by the centralized traffic control (CTC) method of train control, as authorized by the CROR, and are dispatched by an RTC located in Edmonton. A total of 23 wayside inspection systems (hot box detectors) and 2 dragging equipment detectors are located at various intervals along the subdivision.

Traffic on the Rivers Subdivision consists of an average of 35 freight trains and 1 passenger train per day. It is one of the busiest subdivisions on the CN system and transports a significant amount of DG, about 60% of which are Class 3 flammable liquids. Due to the number of car loads of DG transported on the Rivers Subdivision, it meets the criteria to be designated as a “key route.” The total annual traffic (in millions of gross tons per mile) and the DG traffic (in car loads) on the subdivision are listed in Table 3. The DG traffic that traverses the Rivers Subdivision includes over 150 different DG products.

| Year | Total annual traffic (millions of gross tons per mile) | Total DG traffic (car loads) |

|---|---|---|

| 2015 | 107 | 184 824 |

| 2016 | 104 | 89 818 |

| 2017 | 117 | 97 314 |

| 2018 | 123 | 144 789 |

Data source: CN

This section of track meets the criteria of Class 4 track as defined by the TC–approved Rules Respecting Track Safety, also known as the Track Safety Rules (TSR). The authorized track speed for Class 4 track is 60 mph for freight trains and 80 mph for passenger trains. In the vicinity of the accident, the train speed listed in the CN Rivers Subdivision timetable is 50 mph for freight trains and 60 mph for passenger trains. Key trains are restricted to a maximum speed of 50 mph while operating on main track. There is a permanent slow order of 45 mph in effect between Mile 49.5 and Mile 51.0 for both freight and passenger trains. At the time of the accident, there were no other slow orders in place.

In the vicinity of the accident, the rail is 136-pound continuous welded rail. The track structure was inspected in accordance with regulatory and company requirements and was in good condition.

1.10.1 Track configuration and signal conspicuity in the vicinity of the accident

The area of the accident is primarily double-track territory. Equilateral turnouts (with a speed limit of 45 mph) are located at Mile 50.37 and Mile 50.1 in order to transition the parallel north and south tracks to a single main track that traverses the Assiniboine River. Signals 504S and 504N at Nattress are 2-aspect signals permanently positioned on either side of the track (Figure 7).

The signals stand about 15 feet higher than the surrounding area and are designed to be relatively eye-level for an approaching eastbound train crew when the approach to the signal is unobstructed. A dark backing or target is located behind the signal aspect to aid signal indication visibility in bright ambient lighting conditions.

The westward facing signals display indications that govern eastbound movements accessing the equilateral turnout at Mile 50.37 (Figure 8).

From about Mile 50.84 to Mile 50.51 (approximately 1700 feet), the track curves to the left (in the direction of travel for train 318) as the track nears the equilateral turnout at Nattress (Mile 50.37). For an eastbound train operating on the south main track with an unobstructed view, the signal indications at Signal 504S (Mile 50.4) are normally visible from an estimated 1600 feet to the west (Mile 50.7). Beyond 1600 feet, the signals become obscured by brush and foliage along the railway right-of-way.

When the adjacent north track is occupied by a train, the combination of the adjacent train and track curvature obscures the signal indications at Signal 504S (Mile 50.4) up to an estimated 900 feet to the west (Mile 50.57).

1.11 Centralized traffic control system

Train control systems provide for safety during the operation of trains, during track work, and during maintenance on one or more main tracks. In particular, CTC uses track circuits interconnected with signals displayed in the field to control train movements. While the basic fundamentals of CTC are over 100 years old, there have been some improvements over the years, such as newer circuitry. CTC is currently the most advanced method of rail traffic control used by railways for main track train operations in Canada.

A “signal” is the physical location of the signal mast. Each individual light on a signal mast is an “aspect.” The combination of aspects displayed on a signal mast form the “signal indication” that governs the train movement. At each signal location in the field, CTC track circuitry and associated systems allow for the display of a variety of signal aspects. The CTC system displays a combination of red, yellow, green, and sometimes flashing signal aspects to train crews. Signal indications are differentiated by colour, position of colours, flashing of the lights, or combinations thereof.

The CTC system has several types of signals:

- Controlled signals are fixed signal installations situated in the field at the entrance to a block to govern a movement entering or using that block. These signals display a Stop indication until requested to display a less restrictive indication by the RTC. The signal system determines how permissiveFootnote 34 each signal indication will be.

- Advance signals are fixed signal installations used in connection with one or more other signals to govern the approach of a movement to that signal. If an advance signal displays a Clear to Stop indication, it is, in effect, informing train crews of the next potential signal indication.

Signal indications are used to control train movements by visually conveying advance information to train crews about such things as authorities, speed, and other limits within which the train may operate.

Signal indications identify if the block ahead is occupied by another movement, and provide protection against some conditions, such as an occupied block, broken rail, or a switch left open. Signal indications are progressive: the preceding signal indicates what the next signal will potentially display.

Signal indications are displayed on an RTC screen as either a Stop or a permissive indication. On an RTC screen, an advance signal located between controlled signals is actuated by the presence of a train; however, the system does not differentiate between the direction of the train occupying the block. While the CTC system allows the RTC to monitor a train’s progress along blocks in a subdivision, the train’s exact location within a specific block is not displayed on the RTC screen. Only the occupied blockFootnote 35 that the train is in is displayed.

If a train is about to pass beyond an authorized point, the CTC system does not provide any advance warning to either the train crew or the RTC. CTC also does not provide automatic enforcement to comply with speed restrictions in order to slow or stop a train before it passes a restrictive signal.

For this occurrence, the signal logs were reviewed to determine the sequence of signals for train 318. The investigation confirmed that the signal system functioned as designed.

1.12 Canadian Rail Operating Rules governing signals

The following CROR rules provide context for compliance with signals displayed in the field.

CROR Rule 33 states the following:

If speed requirements for their movement are exceeded, crew members must remind one another of such requirements. If no action is then taken, or if the locomotive engineer is observed to be non-responsive or incapacitated, other crew members must take immediate action to ensure the safety of the movement, including stopping it in emergency if required.Footnote 36

CN Special Instructions to CROR Rule 33 further state:

Speeds indicated are maximum authorized speeds between locations named, but do not modify any rule or instruction that may require a lower speed. Maximum speed must be maintained to the extent possible, consistent with safety and efficiency. Unnecessary delays must be avoided.Footnote 37

CROR Rule 34 (Fixed Signal Recognition and Compliance) states the following:

- (a) The crew on the controlling engine of any movement and snow plow foremen must know the indication of each fixed signal (including switches where practicable) before passing it.

- (b) Crew members within physical hearing range must communicate to each other, in a clear and audible manner, the indication by name, of each fixed signal they are required to identify. Each signal affecting their movement must be called out as soon as it is positively identified, but crew members must watch for and promptly communicate and act on any change of indication which may occur.

The following signals/operating signs must be communicated:

- (i) Block and interlocking signals;

- (ii) Rule 42 and 43 signals;

- (iii) One mile sign to interlocking;

- (iv) One mile sign to hot box detector;

- (v) Stop sign;

- (vi) OCS begins sign;

- (vii) Red signal between the rails;

- (viii) Stop signal displayed by a flagman;

- (ix) A switch not properly lined for the movement affected;

- (x) One mile to Cautionary Limit Sign;

- (xi) Cautionary Limit Sign;

- (xii) Advance Permanent Slow Order (PSO) Signs; and

- (xiii) Zone speed Signs where there is a reduction in speed from the previous zone

- (c) If prompt action is not taken to comply with the requirements of each signal indication affecting their movement, crew members must remind one another of such requirements. If no action is then taken, or if the locomotive engineer is observed to be incapacitated, other crew members must take immediate action to ensure the safety of the movement, including stopping it in emergency if required.Footnote 38

CROR Rule 34 does not specify which employee should be the first to call out the signals during a trip.

1.13 Signal indications

Train crews are required to understand all signal indications specified in the CROR and control their trains accordingly. Crew members are expected to know their operating territory, including the location of individual signals. This knowledge is used to facilitate the detection of signals and to help recognize the presence of an imperfectly displayed signal or absence of a signal.

Train crews must communicate their understanding of signal indications displayed in the field to those within hearing distance in the locomotive cab, and take appropriate action to comply with the indication. According to CROR Rule 34, if there is uncertainty, the crew must take immediate action to ensure the safety of the movement, including stopping it in emergency if required.

In this occurrence, eastbound train 318 was proceeding on the south main track when it encountered a progression of 3 signal indications displayed in the field that governed the approach to Nattress:

- The first signal in the progression was 2-aspect Controlled Signal 542S at Mile 54.2, which displayed a Clear to Limited indication (CROR Rule 406). The signal indication identified that the train could proceed, approaching the next signal at limited speed not to exceed 45 mph.

- The next (second) signal in the progression was single-aspect Advance Signal 522S at Mile 52.2, which displayed a Clear to Stop indication (CROR Rule 411) that identified that the train could proceed but must prepare to stop at the next signal.

- The final (third) signal in the progression was 2-aspect Controlled Signal 504S at Mile 50.4, which displayed a Stop indication (CROR Rule 439) because westbound train 315 was still occupying the track ahead.

The signal indications and associated CROR rules that are relevant to this occurrence are detailed in Table 4.

| Signal aspects displayed | CROR rules |

|---|---|

|

Rule 405—Clear Signal—Proceed (at track speed) |

|

Rule 406—Clear to Limited—Proceed, approaching next signal at limited speed (not exceeding 45 mph) |

|

Rule 411—Clear to Stop—Proceed, preparing to stop at next signal |

|

Rule 439—Stop—Unless required to clear a switch, crossing, controlled location, or spotting passenger equipment on station platform, a movement not authorized by Rule 564 must stop at least 300 feet in advance of the Stop signal. |

1.14 Locomotive Trip Optimizer

Trip Optimizer (TO) is a closed-loop energy management systemFootnote 39 that functions similarly to a car’s cruise control system. TO is an industry initiative driven primarily by operational efficiencies. There is no regulatory oversight or rule that governs the use of TO.

TO uses complex algorithms derived from information such as global positioning system (GPS) location, track profile and train characteristics to maintain track speed and reduce train crew errors, and to maximize fuel conservation and reduce in-train forces, all of which contribute to either improvements in safety or operational efficiencies. Once TO has been activated by an LE, the LE is no longer manually controlling the speed of the train. TO automatically controls the throttle and dynamic braking functions while the LE monitors the TO running screen on the Smart Display Integrated System (SDIS) in order to ensure the train’s safe operation and to resume manual control when required. TO is activated and operated through the LE display screen and the screen soft keys. The display screen contains a rolling track map showing the exact location of the train and approaching track features.

TO remains engaged until the LE transitions to manual control mode either in planned areas of manual control or in response to any event that requires the LE to take control to stop the train, such as when operating on a restrictive signal.

TO is disengaged below 12 mph. It neither receives nor responds to any signal indications.

1.14.1 Canadian National Railway Company Trip Optimizer Procedure Guide

The operating requirements in CN’s Trip Optimizer Procedure GuideFootnote 40 specify the following:

When locomotive engineers are trained in TO operation and circumstances permit, TO must be activated and the train operated in Auto Control. However, if an employee is receiving locomotive engineer training, the train must be operated in Manual Control, unless the training is specific to the TO system. Crews must advise the RTC when operating in Auto Control.

As the locomotive engineer, you are responsible for all braking. You must maintain full vigilance and apply situational awareness at all times to ensure the train is operating within safe limits.

You are responsible for controlling the train through any region in which the train is required to stop or operate at a speed less than that given through permanent or temporary speed restrictions.

TO does not consider signal indications or limits of authority. Compliance with all operating rules and safe train handling procedures remains the responsibility of the locomotive engineer.

TO allows Trip Initialization while the locomotive is moving. During this time, you must always be aware of changing conditions outside the cab related to collision avoidance, authority limits and safe train operation.

You must remain cognizant of track signals, train conditions, grade and environmental conditions to ensure that the required stopping distance of the train is preserved.

Anytime the train is operating on a restrictive signal indicationFootnote 41 or is approaching limits of authority, it’s the locomotive engineer’s responsibility to take manual control of the train to meet the reduced speed conditions.

TO does not provide the ability to ensure required stopping distances are preserved. Failure to apply proper vigilance and to provide for adequate stopping distances may result in a train movement passing a signal.

Any anomaly detected by the locomotive engineer which impacts safety shall be a cause for immediate termination of TO use.

1.14.2 Trip Optimizer use on the Rivers Subdivision

When TO is available for a particular subdivision, such as the Rivers Subdivision, it is the preferred method of train operations at CN. Employees are expected to use the system when operating locomotives equipped with TO on subdivisions that are mapped for its use.

To enable the system to operate on the Rivers Subdivision, the track profile, track speeds, switch locations and other subdivision-specific information are pre-loaded into TO, while train-specific information (e.g., train length and weight, as well as temporary speed restrictions) is uploaded into the system for each individual train.

The train 318 LE had used TO on the 9 previous eastbound trips in the month preceding the collision. During these previous eastbound trips, the train 318 LE had always received permissive signals from West Tower (Signal 562) to, and through, Nattress.

1.15 Human factors issues associated with train operations

In railway operations, a variety of human factors issues can have an influence on the outcome of any given situation. In a complex system, such as rail transportation, even the most rigorous set of rules may not cover every contingency and interpretation by individuals. In addition, even motivated and experienced employees are subject to the normal slips, lapses,Footnote 42 and adaptationsFootnote 43 or other mistakes that characterize human behaviour.

1.15.1 Situational awareness

Situational awareness is the perception of the elements in the environment, the comprehension of their meaning, and the projection of their status in the future.Footnote 44 In a dynamic environment, situational awareness requires extracting information from the environment, integrating this information with relevant internal knowledge to create a coherent mental picture of the current situation, and using this picture to anticipate future events. Fatigue can cause lowered vigilance and situational awareness, and reduced attention span.

Shared situational awarenessFootnote 45,Footnote 46 between an LE and a conductor depends on the extent to which the respective situational awareness of each crew member is similar. Train crew members who have a shared situational awareness can anticipate and coordinate their actions, and therefore act with cohesion and efficiency.

1.15.2 Train crew perception of signals displayed in the field

Train crew awareness of signal indications displayed in the field relies on visual detection and perception. A train crew’s accurate and timely visual perception of signals is essential for compliance. The visual perception of signal indications and the associated crew action is a sequential process involving the following steps: detect and see, identify and call, confirm indication between crew members, and adjust train speed accordingly.

Familiarity with a territory improves a train crew’s knowledge of signal locations and enables crew members to take forward-planning (proactive) measures to detect and see signals. The knowledge of signal locations in a specific territory increases with the frequency of trips. When less familiar with a territory, train crews can refer to track schematics provided by CN, which identify the location of each signal. Alternatively, signals can be detected without prior knowledge of their locations; this is considered reactive, as opposed to proactive, detection.

When signal indications are not obscured or obstructed, and there is good visibility, signal perception can be accomplished rapidly from relatively long distances. However, signal perception can be affected by a crew’s fitness for duty, distraction, as well as mental models and expectations.

1.15.3 Mental models and expectations

People use their prior experience and knowledge to rapidly categorize the situation they are experiencing, expect what is to happen next, and select an appropriate course of action based on these expectations.Footnote 47 In highly practiced situations, attention and expectations are often driven by a person’s existing mental model of the situation, given that previous experience will dictate what information is important and how the situation will unfold.Footnote 48

Mental models are critical for effective performance in dynamic time-critical environments because they reduce the need for time-consuming evaluation of the situation and enable quick actions. However, when mental models of situations are inaccurate, they can also lead to errors in how information is perceived, making it less likely for a train crew to detect information that is opposite of what is expected, and to reassess the initial assessment.Footnote 49

1.15.4 Use of Trip Optimizer

When operating a train using TO, the LE’s tasks shift from a proactive, anticipatory driving strategy, toward a more reactive monitoring strategy and lower workload.Footnote 50

Low workload and monotonous tasks can lead to

- increased feelings of sleepiness and tiredness because they reduce an individual’s arousal levels.Footnote 51

- a reduction in vigilance. Vigilance is associated with a state of sufficient alertness to monitor the environment effectively, with a particular emphasis on scanning for stimuli that signal a potential hazard.Footnote 52 Decreased vigilance has been shown to reduce the overall detection rate of critical stimuli over the duration of a task.Footnote 53

- reductions in situational awareness. The U.S. Department of TransportationFootnote 54 compared different levels of train automation (from cruise control to full auto-pilot) and found that, for normal operations, full automation (like TO) facilitated situational awareness of the overall driving task because the automation freed up attentional resources to perform secondary tasks and fault monitoring. However, operators reported they felt out of the loop with the primary task. This indicated potential problems with respect to maintaining awareness of the primary task, especially in the presence of fatigue.

1.15.5 Authority gradient

The concept of authority gradient is universal and has been demonstrated in other transportation modes.Footnote 55,Footnote 56,Footnote 57 When an authority gradient exists, there is usually a difference in level of experience and/or authority between the operating crew members. In these situations, safety-compromising behaviour can be overlooked because a less experienced or subordinate employee is often reluctant to question the actions of a more senior employee.

Railway operations are governed by rules and instructions that place equal responsibility for safe train operations on all crew members. However, when an authority gradient exists between crew members in a locomotive cab, intra-cab crew communication can fail and lead to adverse outcomes. To encourage open lines of communication among crew members, strategies such as crew resource management (CRM) practices can be used.

1.16 Crew resource management

Crew resource management (CRM) is understood to mean the effective use of all available resources—human, hardware, and information—to conduct operations safely and efficiently. CRM includes skills, abilities, attitudes, communication, situational awareness, problem solving, and teamwork.

CRM principles include emphasizing critical cognitive and interpersonal skills with the objective of reducing human error. When operating in a 2-crew environment, crew members must successfully interact with each other, their equipment, and their environment to effectively manage threats, errors, and unexpected events that may be encountered.

From a CRM standpoint, effective communication plays a critical role in the crew’s shared understanding of the situation. However, communication skills require practice and reinforcement to be effective, particularly during periods of high workload or an unexpected situation.

Modern CRM programs highlight barriers to effective communication and provide multiple communication strategies that allow individuals to select the most appropriate strategy, depending on the severity of the situation, the time available, and the other people involved in the communication process.

1.16.1 Closed-loop communication

Closed-loop communication is a technique used to avoid misunderstandings and requires that, when the sender communicates a message, the receiver repeats the message back and the sender confirms whether the message has been received accurately.

A TSB marine investigation reportFootnote 58 recently highlighted the importance of closed-loop communication that incorporates some CRM fundamentals. The investigation identified that the crew relaxed their adherence to operational guidance for navigation, resulting in helm orders that were informal and communication that was not closed-loop, which likely contributed to navigation errors.

In the present occurrence, the investigation determined that communications between the 2 crew members were not always closed-loop, as the callouts by the conductor were not always acknowledged or repeated back by the LE, and the conductor did not confirm that the LE had understood the communication.

1.16.2 Crew resource management in the air and marine transportation sectors

Flight crew actions need to be based on a common understanding of the current state of the aircraft, the intended flight plan, and the threats to crew and flight activities in order to perform in a coordinated, efficient, and safe manner. This common understanding between the crew members is referred to as team or shared situational awareness.Footnote 59,Footnote 60 When this understanding is consistent, crews are better able to effectively anticipate and coordinate their actions to achieve their common goal.

Shared situational awareness is developed and maintained by a crew through a number of discrete and continuous behaviours. These behaviours include in-flight briefings, and identification of key points in the flight, such as those communicated during descent, approach, and landing checklists. These activities are carried out at planned checkpoints to describe current state and future plans, and to provide an opportunity for checking that all crew members have a common understanding.

Continuous behaviours include threat and error management (TEM), callouts of changes of aircraft state and instrument setting or mode, and communication of changes to plans. These behaviours ensure that information and state changes are communicated between crew members to update the shared situational awareness on an ongoing basis.

The 3 core elements of TEM in air transportation are threats, errors, and undesired aircraft states. Every flight has hazards that the crew must manage. These hazards, referred to as threats, increase flight risks and may include environmental threats (adverse weather conditions, runway contamination, etc.) or operational threats (short runways, etc.). TEM stresses the principles of anticipation, recognition, and recoveryFootnote 61 and is based on the proactive detection of threats that could reduce safety margins. Crews can establish countermeasures during the planning stage or during flight, modifying the plan according to circumstances.

Effective error management is associated with specific behaviours by the flight crew, the most common being vigilance, a propensity to ask questions or provide feedback, and assertiveness. Although threats exist and errors occur during most flight segments, they are rarely accompanied by serious consequences, because the crew is managing them effectively.

Transport Canada Civil Aviation (TCCA) has developed updated CRM training standards, which were implemented in the fall of 2019. Under these new standards, air operators are required to provide contemporary CRM training to flight crews, flight attendants, dispatchers, flight followers, ground crew, and maintenance personnel, on an initial and annual basis.

In the marine industry, bridge resource management (BRM) is the effective management and use of all resources, human and technical, available to the bridge team to ensure the safe completion of the voyage. BRM encompasses skills, knowledge, and strategies on effective communication, workload management, problem solving, decision making, teamwork, and situational awareness, especially during critical operations.

Effective communication is a key concept of BRM because it helps to establish a shared mental model among the bridge team. When the bridge team has a shared understanding of how manoeuvres will proceed, team members are able to work together to accomplish these manoeuvres, identify operational or human errors, and intervene as required.Footnote 62