200 Promenade du Portage

Gatineau QC K1A 1K8

Letter addressed to:

Director General, Civil Aviation

Transport Canada

Re :

Aviation safety advisory A19C0138-D1-A1

Viking Air Ltd. de Havilland DHC-3 wing strut attachment inspections

On 26 October 2019, while on approach to Family Lake, near Little Grand Rapids, Manitoba, a float-equipped de Havilland DHC-3 (registration C-GBTU) operated by Blue Water Aviation experienced an in-flight breakup that led to a loss of control and subsequent collision with the surface of the water on Family Lake. The pilot and 2 passengers were fatally injured. The aircraft was destroyed by impact forces. The accident occurred at 0837 Central Daylight Time. The TSB investigation into this occurrence (A19C0138) is ongoing.

The occurrence aircraft was operating under Supplemental Type Certificate (STC) SA95-32, which authorizes operations up to a gross weight of 8367 pounds, and under STC SA01-111, which authorizes operations with the General Electric Aviation Czech H75-200 turbine engine.

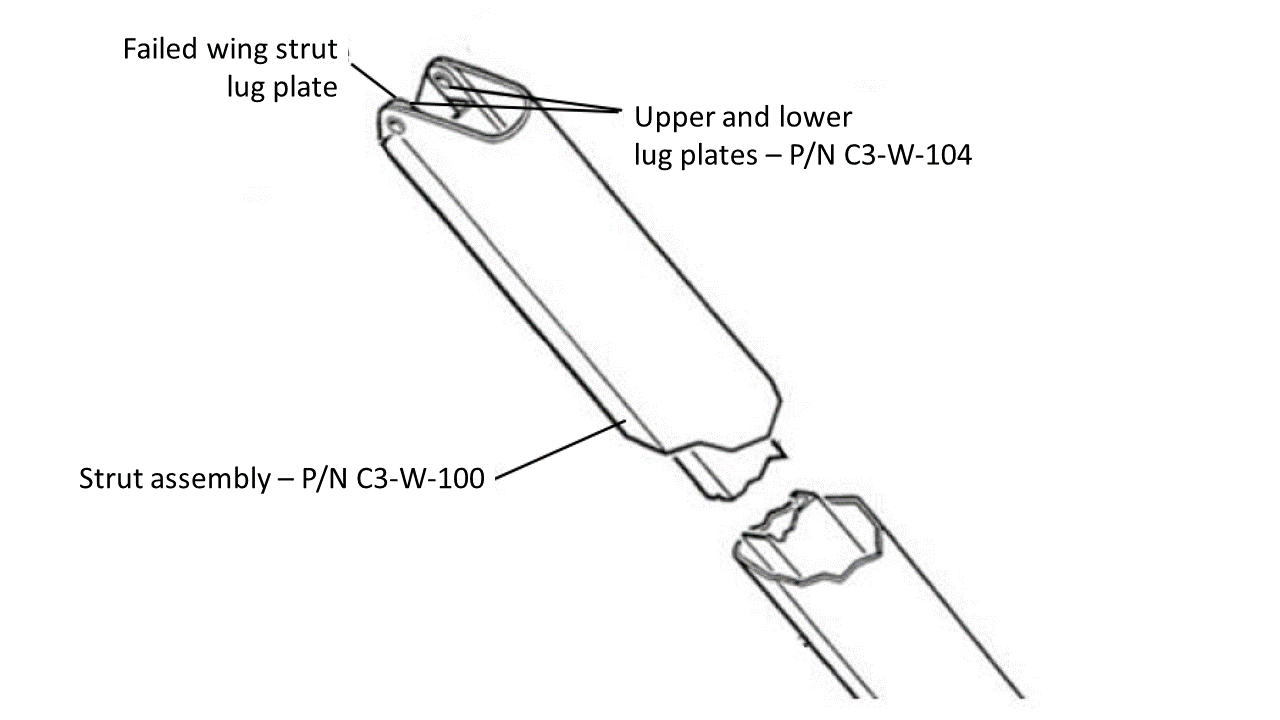

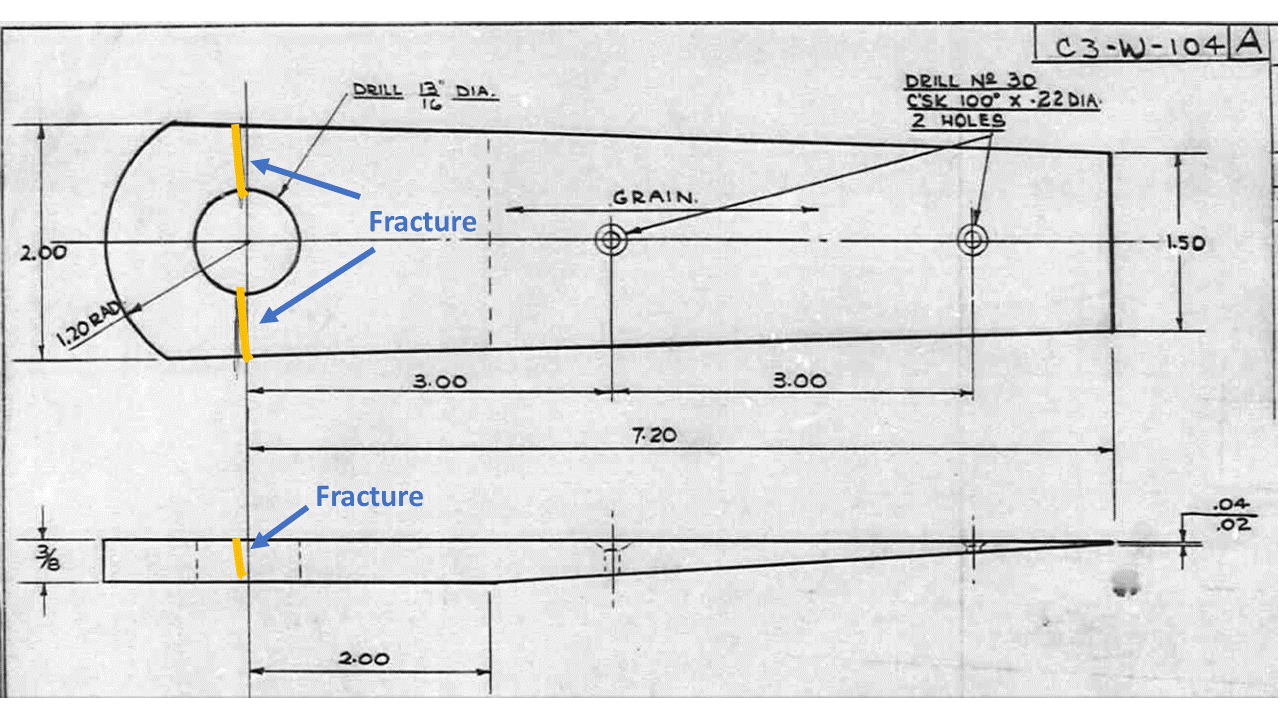

The investigation has revealed that the right wing separated from the fuselage in flight, prior to the impact with the surface of the water. TSB investigators were able to recover the separated wing and noted a suspicious fracture on the lower strut lug plate (P/N C3-W-104) at the strut-to-wing attachment (Figure 1). The failed parts were sent to the TSB Engineering Laboratory in Ottawa, Ontario, for inspection.

The inspection of the failed lower strut lug plate revealed fatigue cracking across the aluminum surface on the trailing edge side of the bolt bore. The fatigue crack originated at the bottom of the bolt bore and propagated over time until the remainder of the lug plate failed under overload forces during the occurrence flight (Figure 2 and Figure 3).

In February 2018, Transport Canada issued Airworthiness Directive (AD) CF-2018-04, which requires operators of DHC-3 aircraft to inspect parts of the aircraft for corrosion, wear, and fatigue cracking in accordance with Viking Product Support Manual (PSM) 1-3-5 DHC-3 Otter Supplementary Inspection and Corrosion Control Manual (SICCM). This manual requires an annual detailed visual inspection (DVI) of the wing strut fittings and attachment lug plates. The operator of the occurrence aircraft last complied with this AD in November 2018.

As a result of this occurrence, Viking Air Ltd. (the aircraft type certificate holder) issued Alert Service Bulletin V3/0011, which calls on operators of DHC-3 aircraft to inspect the wing strut assembly using more advanced and comprehensive methods than those required in the SICCM, such as bolt hole eddy current inspections, fluorescent dye penetrant inspections, and an eddy current surface scan.

As this occurrence shows, the DVI procedure prescribed in the SICCM, as required by AD CF-2018-4, may not be adequate to identify cracks that form in this lug plate area. If more advanced methods, such as those prescribed in the manufacturer’s Alert Service Bulletin are not used, the cracks may continue to go undetected, possibly resulting in a re-occurrence of a similar nature. Therefore, Transport Canada is encouraged to work with Viking Air Ltd. to amend the SICCM or issue a new AD to include inspection requirements outlined in Viking Air Ltd. Alert Service Bulletin V3/0011.

The TSB would appreciate being advised of any action taken in this regard. Upon completion of this occurrence investigation (A19C0138), the Board will release its investigation report.

Original signed by

Natacha Van Themsche

Director of Investigations — Air

Transportation Safety Board of Canada

cc:

- Acting Director, Policy and Regulatory Services, Transport Canada

- President & CEO, Viking Air Limited

Background information

Occurrence No.: A19C0138

This Safety Communication No.: A19C0138-D1-A1