Potentially defective bathtub gondola cars in scrap iron and steel service

200 Promenade du Portage

Place du Centre

4th Floor

Gatineau QC K1A 1K8

16 September 2019

617-09/19

R19T0107

Director General, Rail Safety

Transport Canada

14th Floor, Enterprise Building

427 Laurier Avenue

Ottawa, ON K1A 0N5

Associate Administrator for Railroad Safety

Chief Safety Officer

Federal Railroad Administration (FRA)

West Building W35-328

1200 New Jersey Avenue SE

Washinton, DC 20590

SUBJECT: Rail safety advisory letter 09/19

Potentially defective bathtub gondola cars in scrap iron and steel service

On 28 June 2019, westbound Canadian National Railway (CN) freight train M38331-27 (the train) was a key train operating on the CN Strathroy Subdivision, which is a key route. The train consisted of 2 head-end locomotives, 1 mid-train distributed power (DP) remote locomotive (situated between the 81st and 82nd car) and a total of 140 cars, including 125 loaded cars, 12 empty cars, and 3 residue cars. The train was 9541 feet long and weighed 15 674 tons.

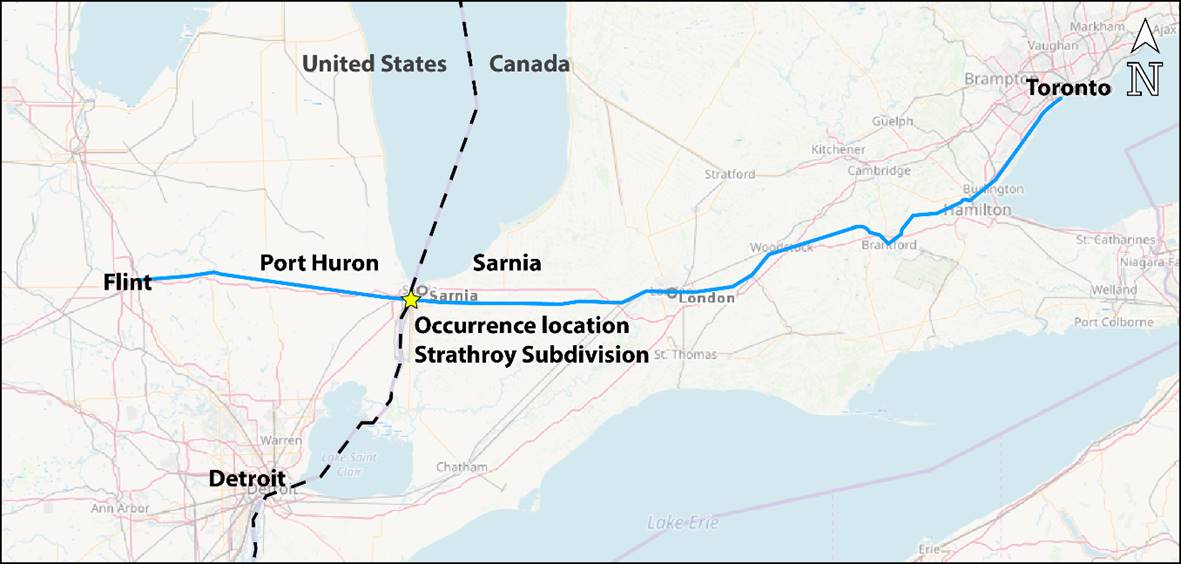

The Strathroy Subdivision consists of a single main track that extends from Mile 0.0 (London, Ontario) to Mile 61.7 (Port Huron, Michigan, United States), where it joins Mile 334.2 of the CN Flint Subdivision. Train movements are governed by the centralized traffic control system method of train control, as authorized by the Canadian Rail Operating Rules (CROR), and are supervised by a rail traffic controller (RTC) located in Toronto, Ontario. The allowable speed for freight trains is 60 mph.

At about 0402 Eastern Daylight Time,Footnote 1 the train, operated by a 3-person crew (i.e., locomotive engineer, conductor and brakeman) departed from Sarnia, Ontario, en route to Port Huron. The train proceeded though CN’s Paul M. Tellier Tunnel (the tunnel) under the St. Clair River, which connects Sarnia to Port Huron and traverses the international border between Canada and the United States (Figure 1).

The track into (and through) the tunnel is mostly tangent Class 4 single main track. The track has an approximate 2.00% descending grade from Mile 59.32 to near the international border (Mile 60.63), where it levels out slightly, followed by an ascending grade of up to 2.10% to just past the west end of the Strathroy Subdivision in Port Huron.

At about 0420, while travelling at 44 mph in the tunnel, the train experienced a train-initiated emergency brake application while the head-end locomotive was at Mile 61.19. Examination of locomotive event recorder data by both the Transportation Safety Board of Canada (TSB) and the National Transportation Safety Board (NTSB) of the United States determined that the initial point of derailment occurred in Canada. The head end of the train came to rest outside the tunnel (Mile 61.46), about 1670 feet west of the tunnel portal in Port Huron.

A total of 46 rolling stock (between lines 51 and 98 inclusive) had derailed and came to rest on both sides of the international border inside of the tunnel. The derailed cars included dangerous goods (DG) tank car UTLX 95205 (line 68), which was loaded with sulfuric acid (UN 1830, Class 8, PG II). During the derailment, this tank car was breached and released most of its load in the tunnel (about 12 000 U.S. gallons).

The trailing end of the 51st car and all wheels of the 52nd car were derailed. Behind (east) the 52nd car, the south rail had rolled and there was a separation of 696 feet leading up to the leading A-end of the 53rd car, bathtub gondola DJJX 30478. The A-end of DJJX 30478 appeared to have collapsed, exhibited extensive damage and had a broken knuckle. The fracture surface of the knuckle displayed brittle fracture characteristics, but had no visible pre-existing defects. The A-end truck of car DJJX 30478 had skewed diagonally and the south rail had rolled to the south side of the tunnel (Figure 2). Car DJJX 30478 was likely the first car to derail.

The adjacent tunnel reinforcement walls and the trailing end of the preceding 52nd car showed no visible signs of impact. There were no obvious track defects.

Following the accident, the TSB and NTSB inspected the head end of the train that had not derailed. As a result of the inspection, 5 cars from the head end of similar vintage and type were identified. These cars, along with wreckage from car DJJX 30478, were set aside for further examination.

In late July 2019, the TSB and NTSB conducted a more detailed examination of the failed car (DJJX 30478) and of the 5 cars of similar vintage and type that were selected from the head end of the train.

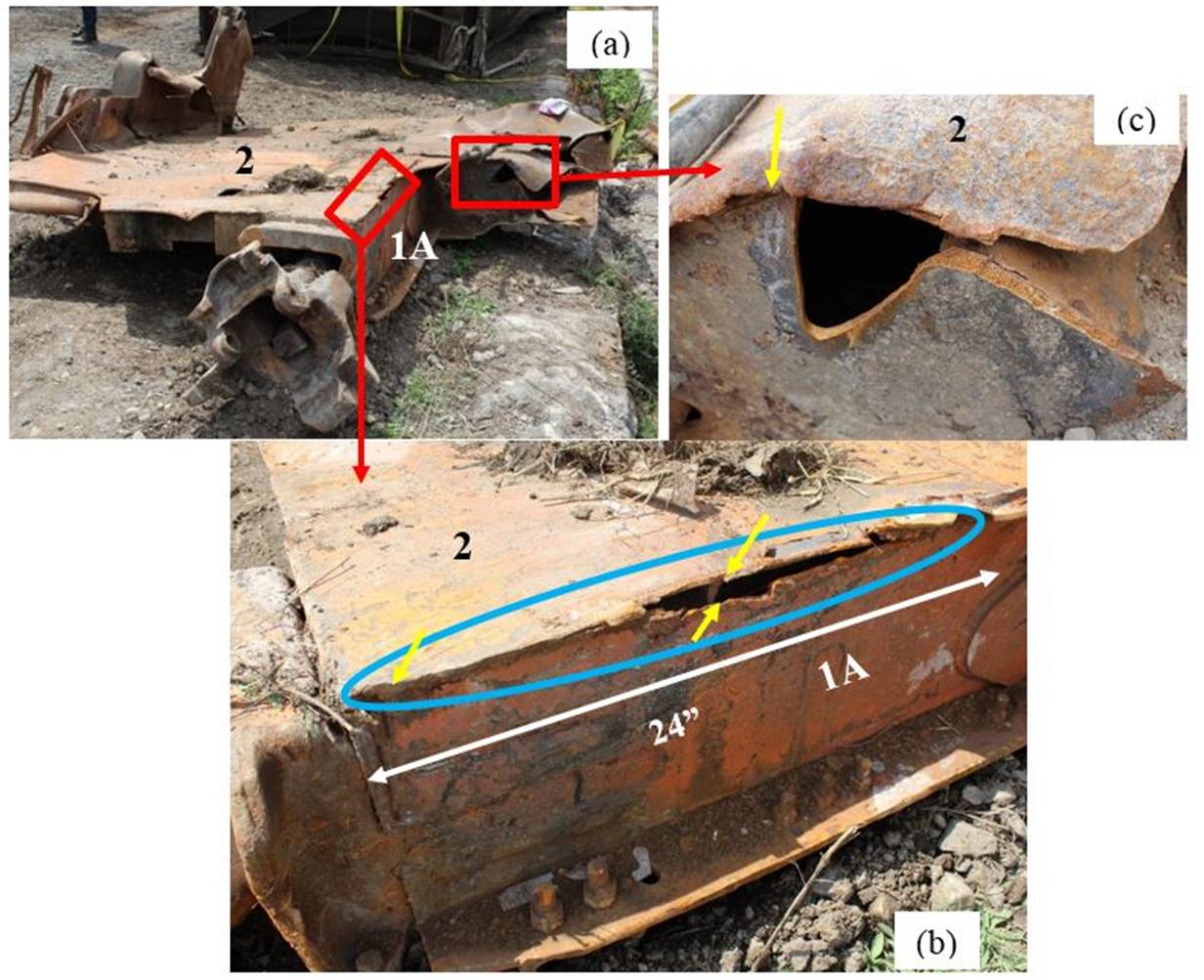

The examination of DJJX 30478 identified that the A-end of the car likely sustained a structural failure when subjected to elevated in-train buff (compressive) forces while travelling within the tunnel. The car had a number of pre-existing defects, such as corrosion and cracks up to 24 inches long in the welds that secured the A-end shear plate to the stub sill, car body bolster and side sills (Figure 3).

Similar pre-existing cracks were observed in the welds that secured the B-end shear plate to the stub sill, car body bolster and side sills (Figure 4).

(a) Bottom of B-end showing stub sill and car body bolster; (b) and (c) Zoomed views of cracks found on the shear plate (yellow arrows); (d) and (e) cracks found in the joint between the car body bolster and side sill (Source: TSB)

Cracks in these areas can result in increased stress and negatively affect the ability to transfer in-train forces through the car structure as per the original design. In some cases, this can result in structural failure. Bathtub gondola car DJJX 30478 was manufactured in 1978 by Berwick Forge, which is no longer in business. The car had initially been used in utility coal service until about 2012, when it was purchased by the David J. Joseph Company (DJJ Company) and placed in scrap iron and steel service. Variations of this car design were also constructed by ACF, National Steel Car and Thrall in the late 1970s/early 1980s. It is not uncommon to find cars of this type (Figure 5) and vintage that have transitioned into maintenance-of-way or scrap iron and steel service.

Based on the examination of the 5 cars of similar vintage and type from the head end of the occurrence train, the following observations were made:

- Two (2) of the cars, which were in good condition, had been extensively repaired and the side sills were reinforced.

- Similar to the failed car (DJJX 30478), the other 3 cars (DJJX 30156, DJJX 950782, and DJJX 950965) exhibited similar cracking in the welds that secured the shear plates to the stub sill, car body bolster and side sills at each end of the car.

On 19 August 2019, the TSB examined 2 additional bathtub gondola cars (TFOX 3251 and TFOX 3279), which were of similar vintage and construction, in CN MacMillan Yard in Toronto, Ontario. Similar cracks to the failed car (DJJX 30478) were also present in each of these cars.

To date, the TSB and NTSB have examined a total of 8 bathtub gondola cars (including failed car DJJX 30478). These cars, which were equipped with stub sills, were each at least 35 years old and were being used in scrap iron and steel service (Appendix A). Defects were present in welds that secure the shear plates to the stub sills, car body bolsters and side sills in 6 of the 8 cars. Some of these cars also exhibited bulges, buckles, cracks and/or sagging in key structural components such as stub sills and side sills.

In May 2018, a U.S.-based railroad had issued an internal early warning letter relating to bathtub gondola cars of similar type and vintage, after having had some of these cars experience a catastrophic failure of the car body resulting from cracks in the side sills. It is not known if this information was shared with the rest of the North American rail industry.

Following the Sarnia Tunnel derailment, CN researched the Universal Machine Language Equipment Register (UMLER)Footnote 2 system and identified about 2130 cars of similar type and vintage that are currently being used in scrap iron and steel service in North America. However, there are challenges with accurately identifying the number of these car types that remain in service. The UMLER does not always identify car manufacturers and does not record the car built date or identify the type of car body centre sill (i.e., full or stub). Consequently, there may be even more than 2130 cars of this type and vintage that are currently being used in scrap iron and steel service throughout North America. To date, CN has inspected 416 of the 2130 cars identified as they come onto CN lines, and has found 149 (36%) with defects.

Given the circumstances of the Sarnia Tunnel derailment, in addition to observations made by other Class I railways and the TSB, it would appear that bathtub gondolas cars, which are equipped with stub sills and were constructed in the late 1970s and early 1980s, may be susceptible to structural failure, particularly if subjected to elevated in-train buff (compression) forces.

The consequences of a freight car sustaining structural failure during train operations can be significant. Therefore, Transport Canada and the Federal Railroad Administration may wish to ensure that railways and car owners have procedures in place to identify, inspect and repair (as required) bathtub gondola cars that are equipped with stub sills, particularly those that are being used in scrap iron and steel service, which were constructed in the late 1970s and early 1980s.

Yours sincerely,

Kirby Jang

Director

Investigations, Rail/Pipeline

Original signed by

Kirby Jang

Director

Investigations, Rail/Pipeline

Cc.

- Assistant Vice President, Safety

Canadian National Railway - Senior Counsel, Regulatory Affairs

Canadian National Railway - Assistant Vice President, Technical Services

Association of American Railroads - Senior Director, Operations and Regulatory Affairs

Railway Association of Canada - Assistant Vice President, Safety and Sustainability

Canadian Pacific Railway - General Manager – Mechanical Services

The David J. Joseph Company – Rail Equipment Group

Appendix A – Bathtub Gondola Cars Examined

| Line | Car # | Car type | Equip Code | Built by - MFG | Built date | Sill Type | GRL | Service |

|---|---|---|---|---|---|---|---|---|

1 |

DJJX 950782 |

Bathtub Gondola - GT |

J312 |

ACFX - ACF Industries |

Oct-80 |

Stub |

263K |

Scrap iron or steel service |

13 |

DJJX 30156 |

Bathtub Gondola - GTS |

E106 |

BERW - Berwick Forge |

Mar-78 |

Stub |

263K |

Scrap iron or steel service |

47 |

DJJX 1576 |

Bathtub Gondola - GT |

J302 |

ACFX - ACF Industries |

May-81 |

Stub |

263K |

Scrap iron or steel service |

48 |

DJJX 882062 |

Bathtub Gondola - GT |

J302 |

ACFX - ACF Industries |

May-81 |

Stub |

263K |

Scrap iron or steel service |

50 |

DJJX 950965 |

Bathtub Gondola - GT |

J312 |

ACFX - ACF Industries |

Dec-80 |

Stub |

263K |

Scrap iron or steel service |

53 |

DJJX 30478 |

Bathtub Gondola - GTS |

E106 |

BERW - Berwick Forge |

Nov-78 |

Stub |

263K |

Scrap iron or steel service |

Mac Yd |

TFOX 3251 |

Bathtub Gondola - GT |

J312 |

National Steel Car |

May-82 |

Stub |

286K |

Scrap iron or steel service |

Mac Yd |

TFOX 3279 |

Bathtub Gondola - GT |

J312 |

National Steel Car |

May-82 |

Stub |

286K |

Scrap iron or steel service |

Background information

Occurrence No.

R19T0107